Blogs

The world of various parts machining is full of important knowledge. Even Prototool, which has been in the machining industry for more than ten years, has a lot to learn and innovate. All we have to do is to calm down and enjoy swimming in the sea of knowledge.

Boss Design: Key Elements, Design Guidelines, Common Problems & Solutions

Understand boss design in injection molding, focusing on key elements, design guidelines, and solutions of plastic molded parts.

Read More >>Strategies for Successful Product Design with the Right Materials

Let's discuss the role of material selection for product design, focusing on collaboration with molders for aesthetically pleasing products.

Read More >>Mastering Precision: A Deep Dive into Dimensional Inspection in Injection Molding

The article focuses on the key function of dimensional inspection in injection molding and discuss using types of equipment for measuring.

Read More >>Mastering Blind Holes and Through Holes in Design

Explore blind holes and through holes from this guide specifically aimed at professionals aiming to improve your parts design skills.

Read More >>The Benefits of Using Plastic Molding for Plastic Pallets

Discover the plastic molding for plastic pallets, which has turned manufacturing into advanced technology with enhanced design features.

Read More >>Gear Mold Design for Plastic Gears

Discover the peculiarities of gear mold design for plastic gears and their key characteristics and specialized manufacturing techniques.

Read More >>General Steps In Medical Device Design And Product Development

Discover the key stages in medical device design and product development, ensuring quality and compliance with strict regulations.

Read More >>Creating Strategic Clearance in Mold Design

Explore the essential steps for strategic clearance in plastic mold design, ensuring efficient machining, assembly, and longevity of molds.

Read More >>Factors Affecting the Prototype Cost or Pricing

Discover key factors affecting rapid prototype costs. A concise guide for understanding and estimating rapid prototype pricing.

Read More >>Powder Coating vs Painting in Prototype Surface Treatment

Discover the key differences between powder coating vs painting in prototype, including application methods, and cost-effectiveness, etc.

Read More >>How Top CNC Machining Factories Handle CNC Machining Defects

This article shows how top suppliers tackle CNC machining defects, revealing the ways your high-quality parts undergo to overcome challenges.

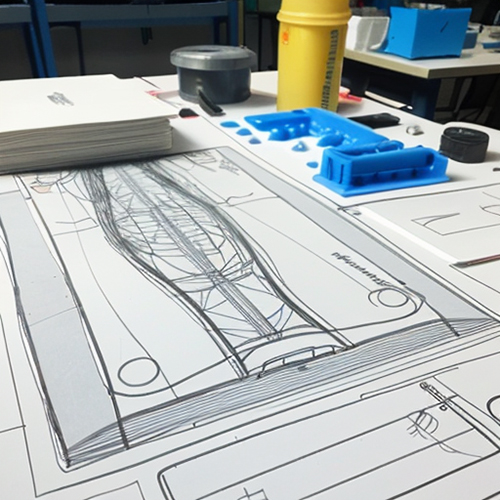

Read More >>The ABCs of Product Styling Design In Industrial Design

Explore the world of product styling design in industrial design. It leads to unique, functional, and aesthetically appealing products.

Read More >>As a Beginner, Which Product Design Software Should I Choose?

Compare the product design software, from CAID and Rhino to CATIA and SolidWorks, and their unique roles in aesthetic and structural design.

Read More >>General Principles of Plastic Part Design For Injection Molding

Experienced product designers deeply understand injection molding processes and consider numerous factors in plastic part design. This article focuses on essential elements such as wall thickness, draft angles, ribs, holes, pillars, snaps, interference fits, and tolerances in plastic molded part...

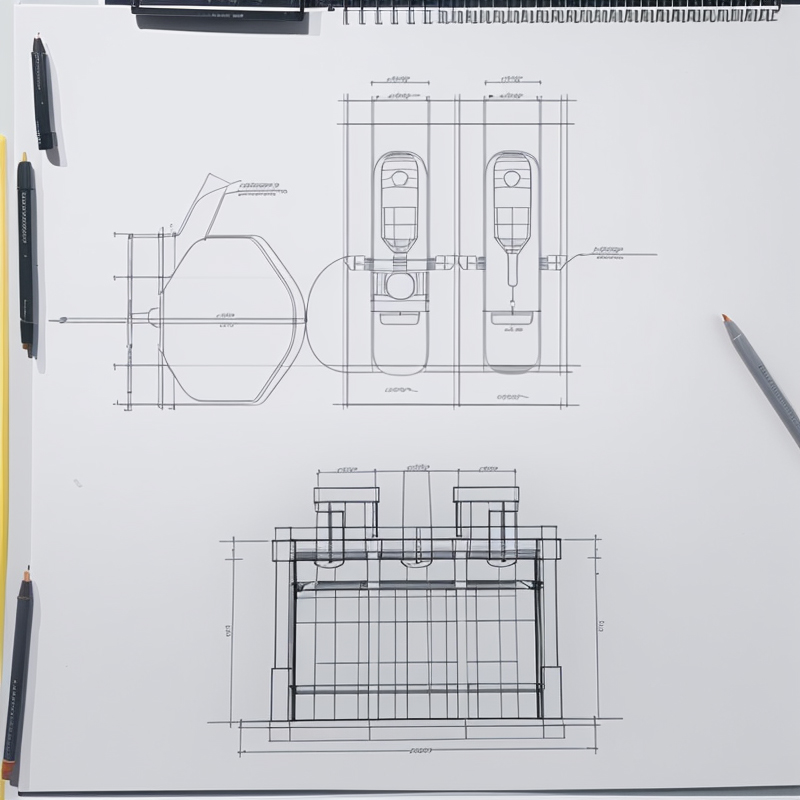

Read More >>What Fundamentals are Needed for Excellent Product Structural Design?

Product structural design refers to the process of designing the physical aspects of products, such as digital devices and home appliances, after their external appearance has been conceptualized. How to understand the definition of “Product Structural Design” This design phase...

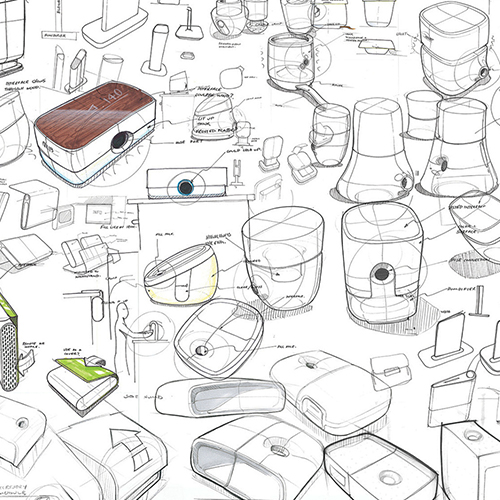

Read More >>Steps to Develop a Successful Product

Steps for successful product development, from idea generation to post-launch evaluation, tailored for entrepreneurs and product managers.

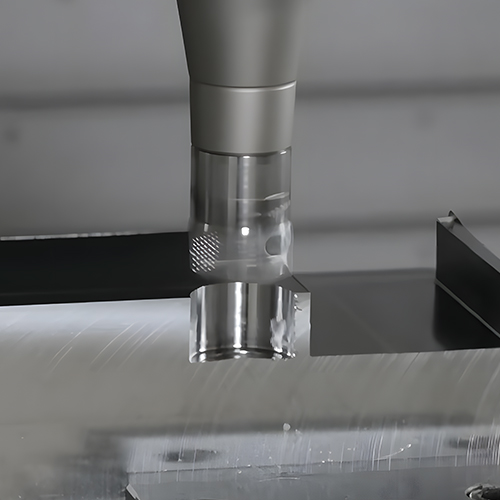

Read More >>Precision in Plunge Milling: Tool Geometry and Cutting Parameter Essentials

If you’re already familiar with basic machining, plunge milling is like adding a powerful tool to your toolkit. Unlike regular cutting, which happens around the edges, plunge milling operations are done right at the end of the tooling. Now, why...

Read More >>Strategic Techniques for Efficient Peripheral Milling Operations

Peripheral milling is a crucial machining operation employed by intermediate and professional manufacturers to enhance metal removal rates and extend tool life. This guide explores various strategies, focusing on plain milling, standard milling, and the distinction between up-milling and down-milling....

Read More >>Side Milling Excellence: A Deep Dive into Techniques and Practical Solutions

Explore side milling about its essential techniques, tool selection, and practical solutions for precision and efficiency in operations.

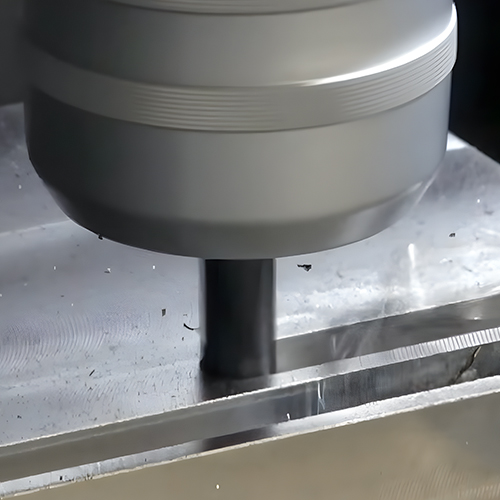

Read More >>Taking Face Milling to the Next Level: Everything You Need to Know

Explore an impressive article about face milling, covering everything from basic to advanced strategies for precision in CNC machining.

Read More >>Optimizing CNC Machining: A Deep Dive into the World of Ramp Milling

When considering precision machining, mastering advanced techniques is not just a skill—it’s a necessity. One such advanced CNC machining technique that should be considered to cater to certain manufacturing needs is “ramp milling.” Why is this essential? Mainly because it...

Read More >>Mold Modification vs. Building a New Mold: What to Choose?

Learn situations where mold modification is sufficient and situations demanding a new mold, along with the cost and steps for modifying it.

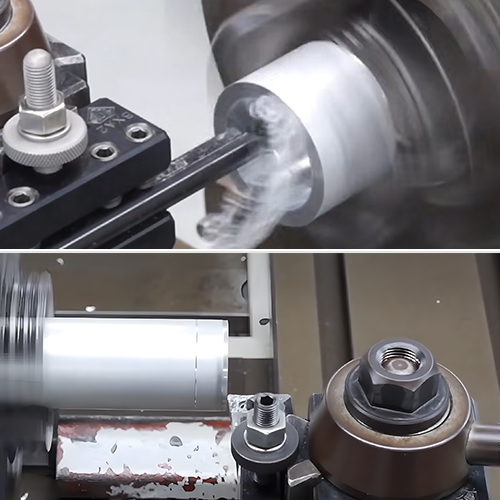

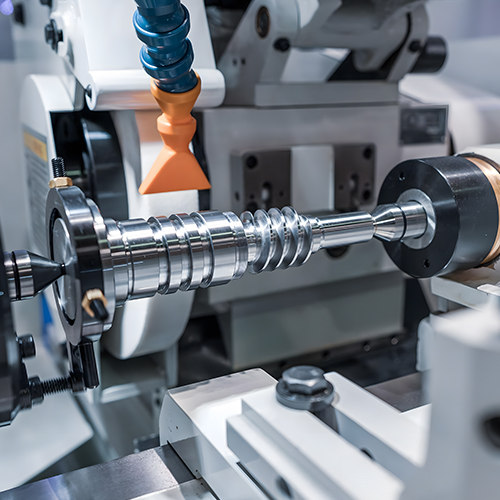

Read More >>Internal Turning vs. External Turning: Understanding the Difference and Usage

Discover the comparison between internal turning and external turning from the mechanisms, tool selection, and advanced strategies.

Read More >>Beyond Basics: Exploring Advanced Taper Turning in Machining

Explore taper turning on lathes, including calculations, methods and key techniques for achieving high-quality parts in CNC manufacturing.

Read More >>What Are The Common Electric Vehicles Molded Parts?

Check the list of common electric vehicles molded parts. Click to learn how these advanced components are made by injection molding companies.

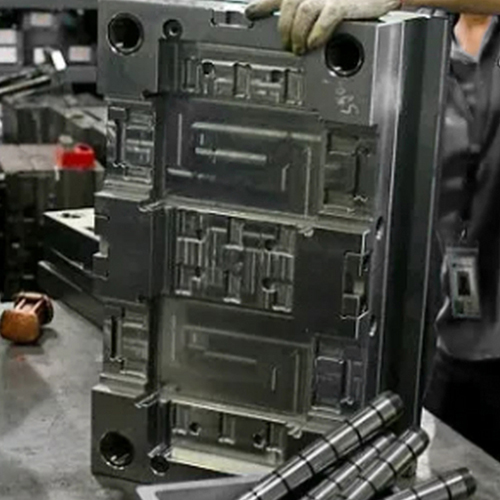

Read More >>The Eight Types of Injection Molds

Explore the types of injection molds used in production. These classifications are based on the structure of the injection mold.

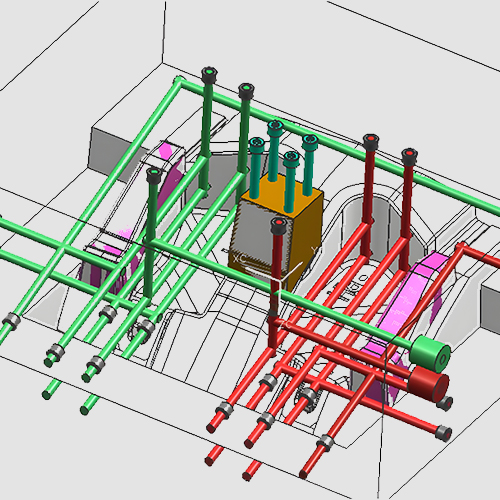

Read More >>Principles of Designing Injection Mold Cooling Systems

Check the key principles for designing effective injection mold cooling systems and see how suppliers ensure the quality of their products.

Read More >>Analysis of Cracking Factors in Large Die Casting Molds

Experienced die casting suppliers analyze the reasons for die casting mold cracking to make customer products more perfect!

Read More >>Understanding the Complete Steps of Mold Closing: Preventing Mold Damage from the Root

See how a good injection molding company can ensure the production quality of their clients' products through the key points of mold closing.

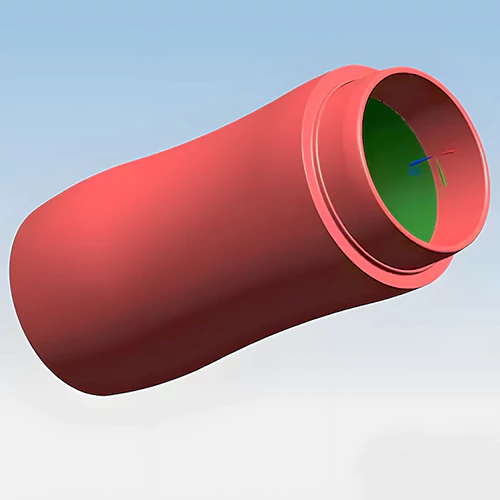

Read More >>Cup Overmold Design Analysis In UG/NX Software

By studying the case of cup overmold design analysis, see how good injection molding companies perfectly complete the whole manufacturing.

Read More >>Key Points and Analysis in Designing Plastic Remote Control Molds

Understand the main considerations, innovative technologies, and standards in plastic remote control mold design used by top suppliers.

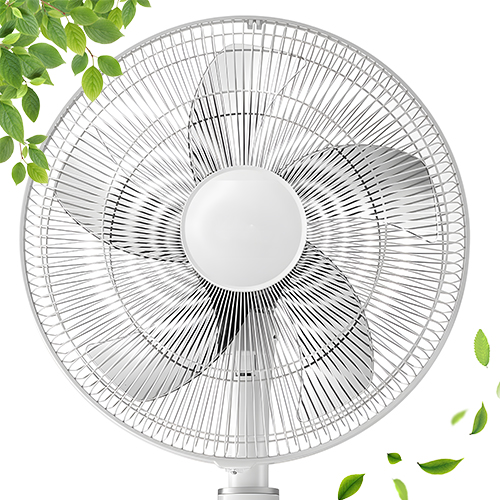

Read More >>Key Points in Mold Design and Injection Molding for a Well-Known Brand’s Fan Blades

Discover the critical aspects of fan blade mold design, including balance principles, material considerations & factory's molding techniques.

Read More >>Soymilk Maker Housing Mold Design Analysis

Explore expert solutions in soymilk maker housing mold design and production. Connect with leading suppliers skilled in crafting high-quality

Read More >>Cosmetic Mold Design Analysis for Cream Jar Lids

Discover how cosmetic molds for cream jar lids are designed and analyzed. Learn about the beauty-focused details important in making molds.

Read More >>Helical Milling: An In-Depth Guide

Learn the applications of Helical milling in drilling, contour milling, and thread machining, and how it enhances precision in metalworking.

Read More >>Unlocking Precision: The Art of Super-Finishing in Manufacturing

Learn about the application of super-finishing from aerospace to medical, and understand how they revolutionize precision.

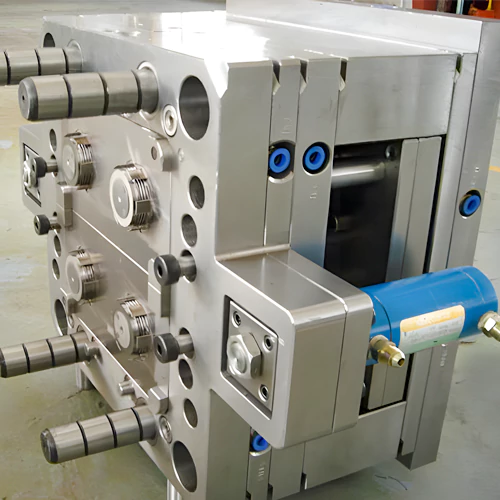

Read More >>Mold Design Essentials: The Importance of Injection Mold Slides

Have you ever wondered how intricate and complex features are seamlessly molded into plastic parts? The answer lies in the fascinating world of injection mold slides. These specialized components are the unsung heroes behind creating undercuts, threads, and other intricate...

Read More >>Maximizing Efficiency and Longevity in Injection Mold Life Cycles

Have you ever wondered how long an injection mold lasts? It’s a tricky question with lots of factors at play. We can’t predict it perfectly, like we can’t predict when a car will break down. But we can estimate. This...

Read More >>Mastering Mold Side Action for Precision Molding

Amidst the evolving global markets and shorter product life cycles, mold design faces escalating challenges, and mold side action emerges as a strategic solution, especially when dealing with intricate part geometries or challenging undercuts. Understanding these scenarios forms the foundation...

Read More >>Decoding Mold Shut-Offs: A Comprehensive Guide to Design and Functionality

Amidst the ever-changing realm of injection molding, it’s crucial to delve into the nuances of mold design. Mold shut-offs, often overlooked but crucial, take center stage to tackle challenging tooling and design hurdles. Think of them as the masterminds working...

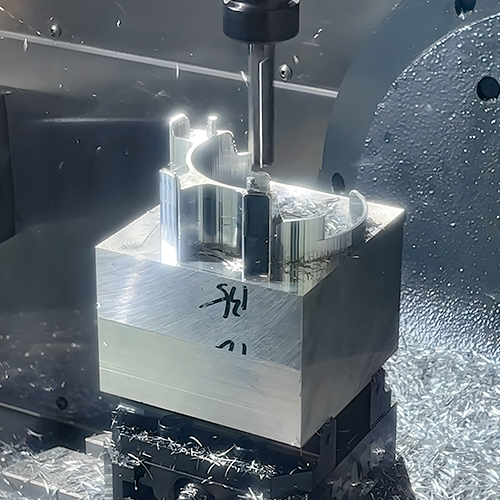

Read More >>Fine-Tuning Your CNC Projects: A Guide to Finish Machining

Surface finish or finish machining, a critical aspect of machining, delves into the fine details of perfecting a workpiece’s external quality and functionality. This precise process involves a meticulous surface adjustment, either by material removal or addition, to meet the...

Read More >>Optimizing Production with Semi-Finishing in Machining

The manufacturing industry highly values the role of semi-finishing. This crucial process involves refining a product to a specific level of completion before reaching the final finishing stage. It is pivotal in ensuring the end product meets the required specifications...

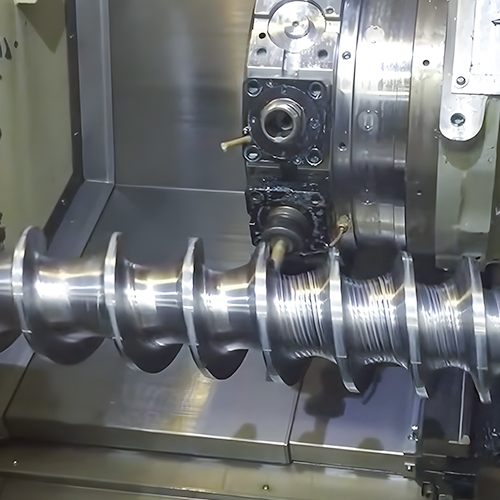

Read More >>From Raw to Refined: Exploring Rough Machining Methods

Rough machining is a process that involves swiftly and efficiently eliminating excess material to bring your workpiece one step closer to its final design. This CNC machining approach employs larger cutting tools, making broad and powerful cuts to eliminate any...

Read More >>Injection Molding Trends: What to Watch For in 2024

The injection molding industry is in constant motion, adapting to emerging technologies, evolving market demands, and growing environmental consciousness. In this dynamic landscape of injection molding industry trends, several key developments in the injection molding industry have taken center stage....

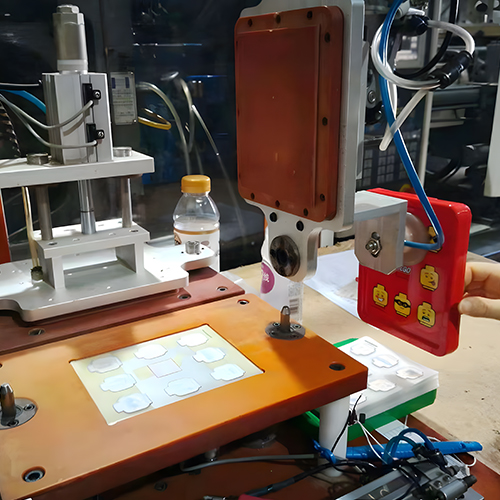

Read More >>The Process Behind In-Mold Labeling

Explore In-Mold Labeling (IML) with Prototool: a game-changer in container production for durability, quality, and efficiency.

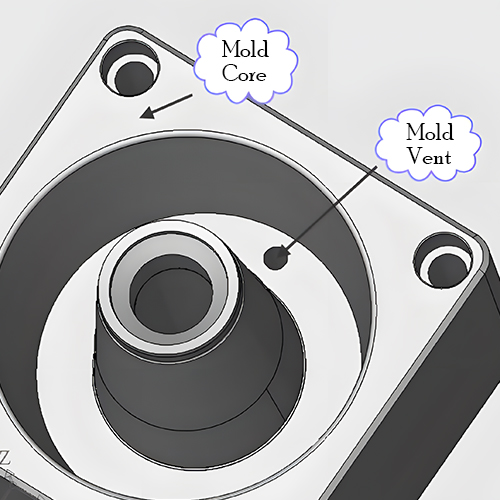

Read More >>Where and How to Vent in Injection Molding?

Learn strategic mold venting placement, methods, and design tips to improve part quality, protect molds, and boost efficiency with Prototool.

Read More >>Guide to Self-Degating in Injection Molding

Explore self-degating in molding: mold opening strokes, its principle, precision gate benefits, 3 tips, and mold finishing comparisons.

Read More >>Essential Tips for Effective Injection Mold Repair

Uncover when and how to repair an injection mold, crucial maintenance parameters, an 8-step repair guide, and 4 major benefits.

Read More >>