Plastic Injection Molding services

The most widely applied plastic injection molding services

- Rapid Lead Times

- 100+ Materials for Choosen

- Strict Quality Control System

- On-demand Production

Certifications: IATF16949:2016 | ISO9001:2015

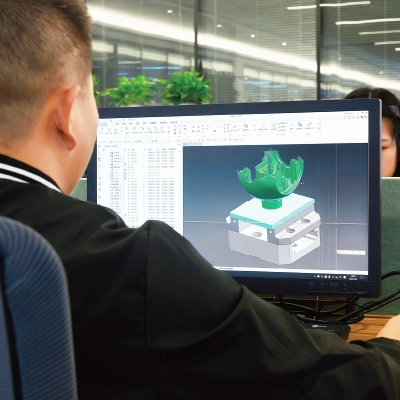

Prototool specializes in plastic injection molding, with a decade of experience that can help you avoid common challenges like insufficient capacity, uncertain design capability, unstable product quality, and untimely delivery. Our expertise extends to various industries, including automotive, aerospace, consumer electronics, and medical. Our injection molding team of 50+ professionals, including designers, programmers, operators, and quality supervisors, work seamlessly with our mold team to deliver exceptional results. Our dedicated and creative team has successfully served hundreds of customers worldwide, earning consistently positive feedback.

Why Choose Us

Experienced Team

- 500+ monthly delivered projects

- 10+ years industry experience

- 100+ high-end technical personnel

Quick Turnaround

- As fast as 7 days

- Free DFM service

- Instant quote within 24hrs

Precision Control

- 10+ Fortune 500 partners

- IATF:16949, ISO9001:2015 certified

- Quality-control team & equipments

In-house Service

- 80+ imported equipments

- 30,000 ㎡ of modern plant

- Cost-effective & superior quality

Global Agility, Localized Excellence

At Prototool, our dual-base injection molding facilities in China and Mexico empower your projects with unparalleled flexibility and compliance. Whether you’re scaling production or navigating regional tariffs, we deliver high-quality, cost-optimized plastic parts tailored to your market.

- Tariff-Smart Production: Choose between our China or Mexico bases to manufacture closer to your target markets, minimizing import duties and logistics costs.

- Speed Meets Precision: Leverage Mexico’s rapid prototyping and high-volume capabilities for North American markets—ideal for just-in-time delivery.

Our Awesome Clients

Find high-quality Plastic Injection Molding Services?

How To Work With Us

The plastic injection molding process may seem simple, but there are many parameters that need to be tightly controlled to ensure the quality and consistency of the plastic components produced.

Submit Request

To obtain a complimentary quote, please provide a product description and technical drawing with your request. Don't have a technical drawing available? Not a problem. We offer reverse engineering services as well.

DFM & Quotation

Our typical response time is within 24 hours. However, please note that the communication process may require ongoing discussions, and the entire process is completely free of charge.

Mold-making

Once the design has been approved, we will start making the mold for your plastic parts. Our team will use advanced technology and equipment to fabricate a high-quality mold that meets your specifications.

Injection Molding

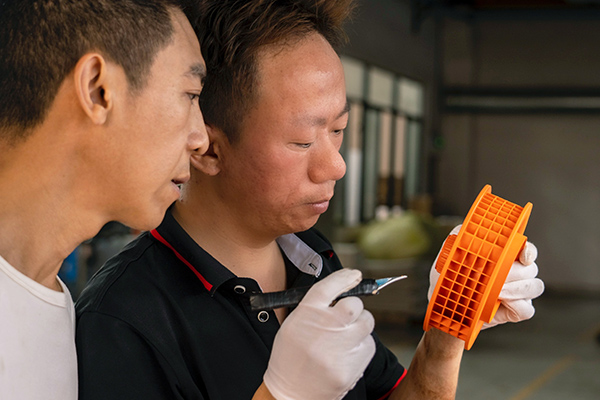

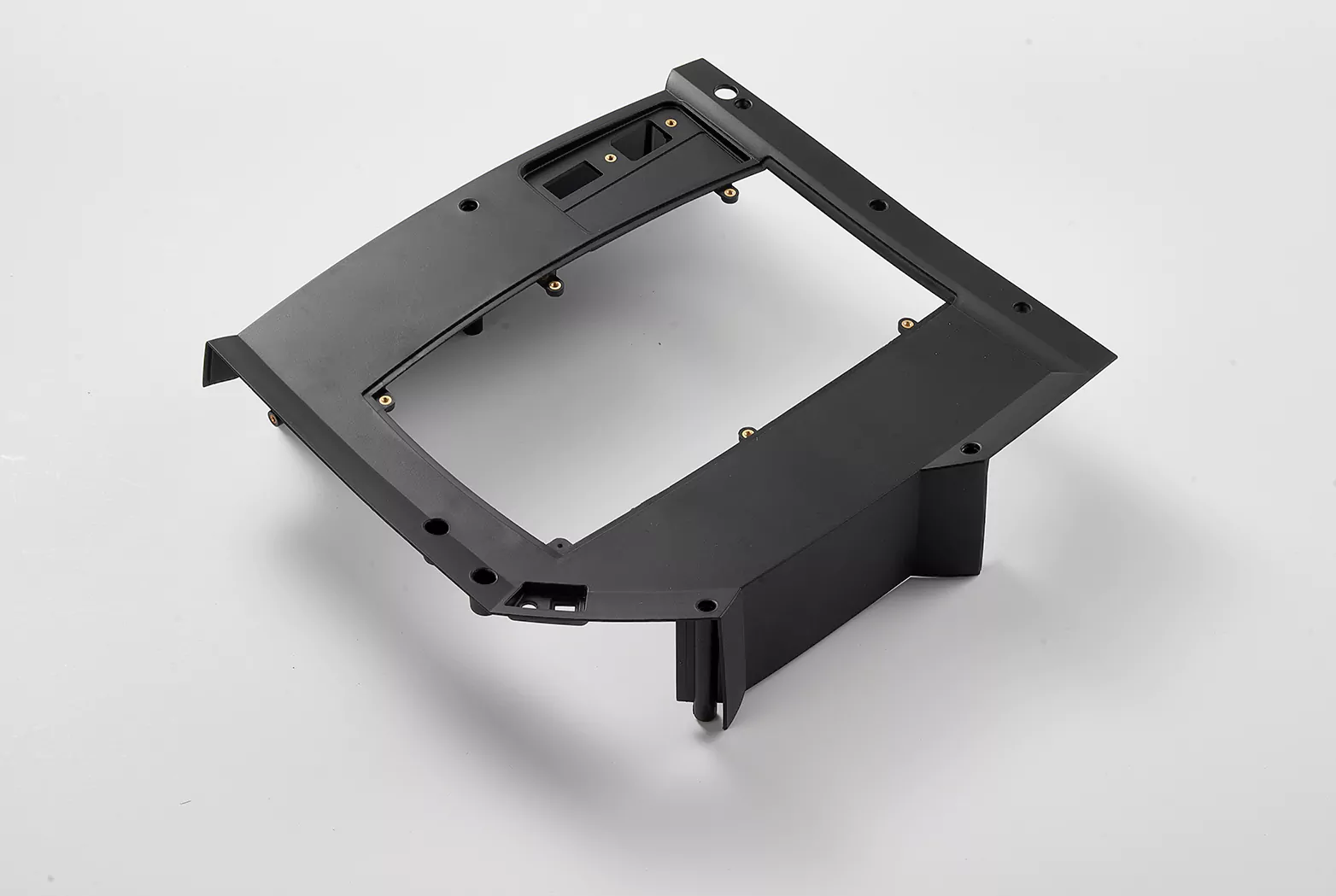

Once the mold is ready, we will begin the injection molding process. Our skilled technicians will use the mold to create high-quality plastic parts consistent in shape and size. We will perform quality control checks throughout the process.

Tolerance

Factors affecting the tolerance of injection molded parts include plastic properties, product design, mold design, injection molding process, etc. When we talk about injection molding product tolerances, it’s better to consider the appearance and function of the finished product and the cost.

Usually, Prototool takes DIN 16742 as our injection molding tolerance standard, and for the automotive industry, we comply with the QC-T-29017-1991 automotive industry tolerance standard as our standard. When the customer has special tolerance requirements, we strictly follow the requirements.

The Plastic Injection Molding Process

1.Clamping

The core and the cavity are the two main pieces of an injection mold. In the first step, during clamping, these two parts of the mold will be extruded and fit together by the machine.

2. Injection

3. Dwelling

Next is the dwelling phase, where the melted plastic is filled to the entirety of the mold through pressure. The pressure is applied directly to the mold such that the liquid fills all mold cavities, and the product comes out accurately and is identical to the mold.

4.Cooling

This process step allows the time needed for the mold to cool. If this step is performed too hastily, the products may stick together or become distorted when demolding.

5. Mold Opening

This is the opposite process of clamping. In this step, a clamping motor slowly opens the two parts of the mold to make for the safety and stability.

6. Ejection

Materials Used for Plastic Injection Molding

ABS

ABS/PC

Acetal

Delrin

ETPU

HDPE

LCP

LDPE

LLDPE

Polypropylene

PPA

PPE/PS

PS

PSU

TPU

Finishing

We offer multiple finishing options to complete the plastic products made with the plastic injection molding process. You can choose from any of the following depending upon your application’s requirements:

Standard Finish

Interior, non-cosmetic finish according to the geometry of the mold.

SPI Finishes

Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish. These Finishing options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Threaded Inserts

We can install the most commonly used and popular standard inserts in UNF and metric sizes.

As Molded

As the name suggests, the mold will remain ‘as it is’ – without any secondary texturing or polishing.

Mold Texturing

Creating textures on the molds so that it shows on the final product. This finishing option includes matte, swirls, patterns, and lines.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

Pad Printing

Application of an ink-based design to the surface.

Painting

Painting the surface with standard colors or Pantone matching, including Primer and topcoat. Masking available; EMI (copper) paint.

Industry Application

The Plastic Injection Molding services by us have a large variety of applications across all industries, including:

Aerospace and Defense

Automotive

Consumer Products

Design Services

Education

Electronics and Semiconductors

Medical and Dental

Energy

Hardware Startups

Industrial

Robotics

Supply Chain and Purchasing

Our Strengths

Industry Expertise & Guidance

Our team of plastic injection molding experts is here to build you a plan for success for prototyping, design validation, and production applications.

Production-Grade Tools

We offer production-grade tooling to all our clients with cost-effective and quick solutions.

Complex and Custom Designs

We run tight tolerances and 2D drawings for a wide variety of industries. No matter the complexity and personalization involved, we can make it happen for you.

Plastic Injection Molding FAQs

Get answers about Plastic Injection Molding Services that could be essential for your particular needs.

How do I get a quote for plastic injection molding services?

To receive a quote, please provide us with detailed information about your project, including part designs or drawings, material specifications, and the quantity of parts needed. Any additional requirements, such as finishing or assembly, should also be mentioned.

What types of plastic materials can be used in injection molding?

We work with a wide range of thermoplastic materials, including ABS, polycarbonate, polypropylene, and more specialized resins like PEEK and TPE, depending on the part’s requirements for strength, flexibility, and thermal resistance.

What is the minimum order quantity for plastic injection molding?

Our minimum order quantity varies based on the project. We accommodate both small batch and large-scale production runs, offering flexibility to suit different client needs.

Can you assist with part design for injection molding?

Yes, we offer part design assistance to ensure your designs are optimized for injection molding. This includes advice on wall thickness, rib design, and gate placement for efficient manufacturing.

Are there any design constraints in plastic injection molding?

Design constraints include considerations for mold flow, part ejection, and cooling. Designs should avoid undercuts, maintain uniform wall thickness, and consider draft angles for easy part release.

Can you produce high-precision parts with tight tolerances?

Yes, our plastic injection molding process is capable of producing high-precision parts with tight tolerances. We use advanced machinery and rigorous quality control to ensure precision.

What finishing options are available for injection molded parts?

We offer various finishing options, including painting, plating, silk screening, and texturing, to enhance the appearance and functionality of the injection molded parts.

How do you ensure quality in injection molded parts?

Quality is ensured through stringent process control, regular inspections, and adherence to industry standards. We conduct various tests to verify the dimensional accuracy, material properties, and overall quality of each part.

How do you ensure the confidentiality of proprietary designs in injection molding projects?

We take the confidentiality of our clients’ designs very seriously. We use secure data handling practices and can enter into non-disclosure agreements to protect your proprietary information.

How do you handle short-run or low-volume injection molding projects?

For short-run or low-volume projects, we offer flexible production options and can use more cost-effective tooling solutions to make the process viable and efficient for smaller quantities.

Do you offer mold flow analysis during the design phase?

Yes, we conduct mold flow analysis to simulate the injection molding process, which helps in optimizing the mold design and ensuring the quality of the final part.

How do you ensure color consistency in injection molded parts?

Color consistency is achieved through precise color matching and the use of quality colorants, along with consistent processing conditions throughout the production run.