Overmolding Services

Combining different materials for enhanced functionality with overmolding services

- Improved Aesthetics

- Strong parts

- Durable Bonding Solutions

- As fast as 1 day delivery

Certifications: IATF16949:2016 | ISO9001:2015

Although in some cases Prototool may recommend you choose our factory’s two-color injection molding technology to complete your particular products, we may also recommend overmolding if you have loose deadlines and want to reduce costs.

Overmolding is obviously a very mature injection molding process in the market. Our professional staff will provide you advice according to our nearly 10 years of injection molding experience to make your products competitive in the market.

Why Choose Us

High-Quality Standards

From using the best materials to employing efficient workflows, precise measurements, and timely deliveries - we follow strict quality control measures to guarantee that only the highest quality parts are produced.

Cost-efficiency

We use advanced automation procedures and other techniques to make sure that the project remains cost-effective for you, suiting your budget.

Excellent Capacity

We have an efficient and exceptional in-house capacity and capabilities, helping us ensure that your parts are made with top quality industry standards from start to finish.

Quick Turnaround

We ensure faster lead times and quick turnaround with our rapid services. We help you reach the market quicker by shortening lead times to weeks or even days.

How Does Our Overmolding Services Work?

Here is the typical working order to expect when you hire us for our overmolding services:

Submit Request

Submit quote request with a description and technical drawing of your product. In case of no technical drawing, no worries. We can reverse engineer.

DFM & Quotation

We usually get back to you within 24 hours.

Mold-making & Machining

Once you approve the quote and make the deposit, we start working on the mold making and machining process.

Shipping

Packaged, labeled, and shipped to your door right on time. You can easily reorder the parts from your molding tool.

Find the Best Overmolding Service?

This is where you get it all. Request your free quote today, and enjoy the best overmolding services.

Different Types Of Overmolding Processes

There are different types of overmolding processes, each of which has different applications. Here are some of the most common types of overmolding structures:

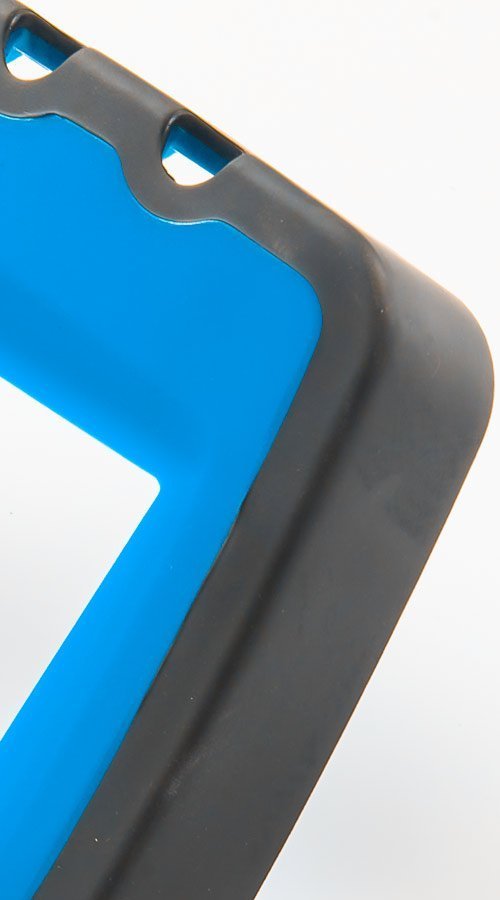

Plastic Over Plastic

This involves the molding of a rigid plastic material, which is later overmolded with another rigid plastic. These plastics can be of different colors, structures, and resins.

Rubber Over Plastic

This involves the molding of a rigid plastic material. Once molded, this plastic is then overmolded with soft rubber or TPE.

Plastic Over Metal

First, a metal substrate is machined, cast, or formed. Then, it is inserted into an injection molding tool, and the plastic is molded over or around the metal.

Rubber Over Metal

First, a metal substrate is machined, cast, or formed. Then it is inserted into an injection molding tool, and the rubber or TPE is molded over or around the metal.

Materials Used for Overmolding

We offer a wide range of materials for overmolding projects, depending upon the geometry, complexity, and requirements of your project. These materials can be divided into three different categories, including:

Rigid Plastics

ABS

Polypropylene

Polycarbonate

Acrylic

Nylon

POM

PTFE

PBT/PBT-PC

PEEK

HDPE

PVC

PPS

PI

PAI

UPE/UHMW

PVDF

ULTEM (PEI)

Flexible Plastics

PE

PS

PET

EVA Foam

EPS Foam

PU Foam

Rubber Plastics

TPE

TPU

Silicon Rubber

Finishing

We offer multiple finishing options to complete the products made with the overmolding process. You can choose from any of the following depending upon your application’s requirements:

Standard Finish

Interior, non-cosmetic finish according to the geometry of the mold.

Mold Texturing

Creating textures on the molds so that it shows on the final product. This finishing option includes matte, swirls, patterns, and lines.

SPI Finishes

Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish. These Finishing options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

Threaded Inserts

We can install the most commonly used and popular standard inserts in UNF and metric sizes.

Pad Printing

Application of an ink-based design to the surface.

As Molded

As the name suggests, the mold will remain ‘as it is’ – without any secondary texturing or polishing.

Painting

Painting the surface with standard colors or Pantone matching, including Primer and topcoat. Masking available; EMI (copper) paint.

Industry application

Overmolding is used to produce customized parts and components for a wide variety of industry applications, including:

Our Strengths

Specialized Services

We offer end-to-end specialized overmolding services to meet your specific design requirements.

Tailored Solutions

From design to final fabrication and packaging, our team of experts will work with you every step of the way to create a tailored solution for your exact needs.

Diverse Material Options

With a variety of materials available and the precise capabilities of our equipment and facilities, we offer highly customizable overmolding services for all your project needs.

Online quote system

We give our customers instant access to a technical team with our online quote system. Once a quote is submitted online, you will have a response within 24 hours.

Overmolding FAQs

Gain important knowledge about Overmolding Services that could be essential for your particular needs.

What is a substrate in overmolding?

The first “shot” is called the substrate, which is typically the more rigid of the two materials being used and is designed to accept the subsequent shots or overmolds.

What is the difference between an overmold and a substrate?

Where the substrate is the first material injected into the mold, the overmold is the second. The substrate is designed to accept the overmold onto or around itself. The substrate is typically more rigid than the overmold.

How do I get a quote for your overmolding services?

To get a quote, please provide us with details of your project, including part dimensions, material specifications, and volume requirements. If available, technical drawings or 3D models are also helpful.

What if I am unable to provide you with a technical drawing when requesting a quote?

If you don’t have a technical drawing, describe your project in as much detail as possible and provide any sketches or reference images. Our team can assist in developing technical drawings if needed.

Can you assist with material selection for overmolding?

Yes, we can guide you in selecting suitable materials for both the substrate and the overmold to ensure compatibility and meet the functional requirements of your part.

What is the minimum order quantity for overmolding projects?

Our minimum order quantity varies depending on the project’s complexity. We cater to both small and large-scale production runs, offering flexibility to meet diverse client needs.

How long does the overmolding process take from start to finish?

The timeline depends on the project’s complexity, mold design and manufacturing time, and the production volume. We can provide a more accurate timeline once we review your project details.

Are there any design constraints I should be aware of for overmolding?

Design constraints include ensuring proper adhesion between materials and accounting for different shrinkage rates. Our team can review your design and suggest any necessary modifications.

Can overmolding be used to improve the durability of a part?

Absolutely. Overmolding can enhance a part’s durability by adding a protective outer layer, which can provide additional shock absorption, wear resistance, or environmental protection.

What types of products are typically created using overmolding?

Overmolding is commonly used for products like tool handles, medical devices, electrical components, and consumer goods that require a soft grip or a durable, sealed exterior.

How do you ensure a strong bond in overmolded parts?

We ensure a strong bond by carefully selecting compatible materials and optimizing the molding process parameters, such as temperature and pressure, for effective material adhesion.

Can overmolding be used for prototypes as well as production?

Yes, overmolding can be used for both prototyping and full-scale production. Prototyping is often a valuable step for testing the design and functionality of overmolded parts before mass production.