Injection Molding Services

Our injection molding services specializing in serving global customers for more than a decade

- Design + Manufacturing one-stop solution

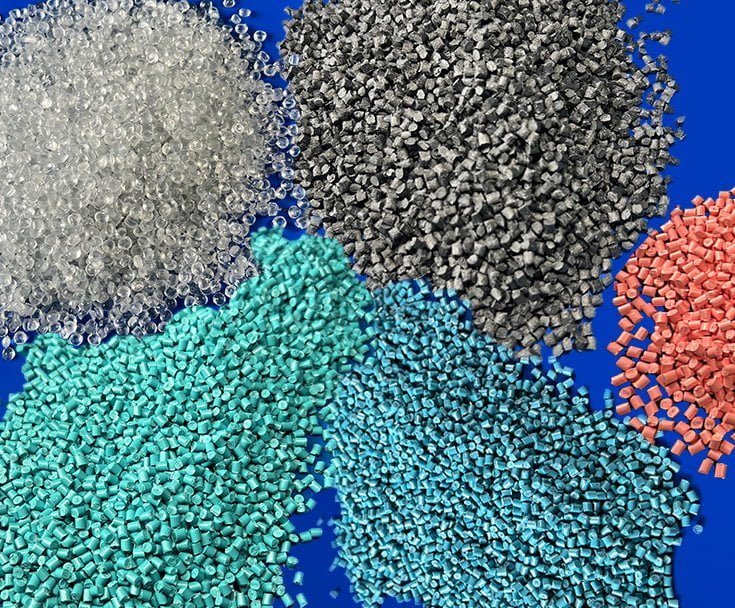

- 100+ Material & color options available

- Highly efficient & faster turnarounds

- Clamping force up to 1000T

Certifications: IATF16949:2016 | ISO9001:2015

A good injection molding factory must have rich experience, well-equipped equipment, professional staff in all positions, customer-oriented corporate culture and good service consciousness.

Yes, Prototool is such a company best for you. Our injection molding services have been serving a wide range of sectors, including the automotive, cosmetics, consumer goods, and many others for more than ten years. Based on our experience, we understand what every client desires the most when they engage in one-stop injection molding collaboration with us.

Why Choose Prototool for Injection Molding?

10+ Years Professional one-stop service

We offer a distinctive array of experienced and passionate team members in our plastic molding services. They guarantee a high-precision final product, from the initial mold design and creation through to the manufacturing process and secure delivery to your location.

100+ & Custom materials for choosen

PPS, PP, POM, ABS, C-GF, HDPE, LDPE, PBT, TPV, PC, POE, PMMA, PA66, PA-GF, PS-PPE, TPE, TPU and more. We immensely value our customer’s business needs, so we can process customers provided injection molding materials too.

High-Caliber Molding, Budget-Friendly Pricing

While we may not claim to offer the cheapest injection molding services in the world, we assure you that our pricing represents the best value for your money. Over the past decade, we've tirelessly worked to enhance the quality of our clients' products. This commitment involves upgrading the precision of our injection molding machines, continuously learning about new and modified materials, and applying this knowledge in practical ways to deliver exceptional results.

Leading-Edge Internal Manufacturing Capabilities

Our injection molding expertise is backed by over 100 advanced machines with clamping forces up to 1000T. We are committed to staying at the forefront of technology, continually investing in our equipment; This ongoing investment plan is a testament to our dedication to excellence in injection molding. Our in-house capabilities extend to custom mold design, material specialization, swift prototyping, automated production lines, rigorous quality assurance, comprehensive finishing options, large-volume production, and environmentally responsible practices.

Collaborate with Us for Your Injection Molding Needs

Initiate Your Own Project

Start by requesting a quotation with full description and 3D technical drawing of your product for our precision injection molding services. Our engineers are standingby whether it's complex design or simple part--you come first!

Free DFM Analysis & Quote

We try to respond within 24 hours. After receiving your request, we'll take the time for a thorough rendering of DFM with our corresponding quotation on custom injection molding services that are suited specially to you alone.

Mold Making & Molding

Once you approve the quote and we are informed of your deposit, our people prepare the machines and begin on mold design fabrication. After that, we'll start the injection molding production for your projects.

Post Treatment & Reliable Delivery

All of your injection-molded parts are well packed, properly labeled and sent direct to you in good time. See how effective and dependable our machine processing and quality assurance is!

Efficient, Cost-Effective, Durable and High-Precision Injection Molding Service

We are the best in class for injection molding. Order us now! You’ll find it well worth your while when you will use our products and it will definitely bring value to your business.

Our Advanced Injection Molding Options

We can produce thousands of parts to pace up your product development cycle. You can choose from a large variety of materials. We keep over 100 plastic resins materials in the inventory to kick start the production. For molded end products, we have many finishing options. Our injection molding capabilities are plastic molding, insert molding, over molding, and family molding.

We employ finest thermoplastic materials to produce superior quality injection molded parts. We scientifically execute whole process from gathering requirements to design evaluation, die and mold production and up to final product.

In insert molding, we use a pre-manufactured part (mostly a metal) which is inserted into a mold. To get the final product, preformed mold is over molded with required thermoplastic resin. Availing our insert molding services, you can have exceptional quality products.

In over molding process, we can mold a thermoplastic material into a second thermoplastic or liquid silicone rubber material. Which provides us the ability to achieve required product attributes and functionality.

When customer demands speedy project deliveries then we use family injection mold. It gives us the ability to manufacture multiple parts with the same material in a single cycle. This injection molding technique has more than one cavity cut into the mold. Each cavity can make different part.

Materials Options for Injection Molding Services

We can process numerous plastics and polymers. We have in-house capacity of a large collection of different injection molding materials. That includes PPS, PP, POM, ABS, C-GF, HDPE, LDPE, PBT, TPV, PC, POE, PMMA, PA66, PA-GF, PS-PPE, TPE, and TPU. We can process customers provided materials too.

Different Surface Finishing Options

With various surface finishing options, Prototool can make your injection molded products look and work better. Different finishing methods can be chosen for different needs. Below are some of the techniques we use to refine your injection molded parts:

Bead Blasting

Bead blasting is a way in which injection molded parts are cleaned and refined. It uses high-pressure glass or steel beads to blast the surface into a uniform, matte finish. It's a good method if you want to look uniform and professional.

Pad Printing

The multi-functional pad printing process is excellent for applying company logos and brand names, as well as all kinds of decorative designs, to the surface of injection molded products. This is a good choice if you're looking to customize your own personalization and increase the attractiveness of your parts.

Etching

To raise the roughness of injection molded parts, our surface etching method is used. By chemical or physical means, we can create texture and finish that meets your needs.

Laser Finishing

Injection molded parts can undergo laser surface treatment. This is a very exacting thermal process. It engraves fine lines and pictures, firm company taglines or little logos with great precision. It can heat up to several hundred degrees Celsius by absorbing the light on its surface layer.

Industrial Application of Injection Molding

Due to its manufacturing friendly properties, injection molding is being harnessed in many sectors in the world. It is employed in almost every industry in one or the other way.

Marine

Robotics

Oil and Gas

Transportation

General Goods

Our Capabilities for Injection Molding

We have decades of experience of manufacturing injection molded parts. We have served numerous industries. We are fulfilling the needs of various industries not locally but also globally with our strong commitment to deliver excellence through our services and generate value for our customers.

Well-Equipped and Advanced Machines

We keep on updating our machines with the latest models to be a leading name in this sector. Our R&D department works very hard on research and development. So that we can thrive ourselves in serving our customers and helping them to achieve their business targets.

Quick Services

When anyone reach out to us to acquire our services, we inquire customers’ requirements and propose them the best options. After approval, a dedicated team consisting of designers, engineers, technicians and QC experts starts immediately working on the project. They ensure quality productions in timely manners.

Superb Durability and Efficiency

Well-Equipped and Advanced Machines

FAQs For Injection Molding Services

Get essential information about Injection Molding Services that may prove invaluable to your needs.

How do I Come to know Whether Injection Molding Service is Suitable for my Business or Not?

If you are confused whether this service is meant for your business needs or not. Then don’t worry! You just contact us. We ask your requirements and your product use. After doing assessment, we will let you know if injection molding is suitable for you or not.

What Injection Molding Capabilities do you have?

We are exceptionally capable to provide reliable and efficient injection molding services. Our state of the art machinery and seasoned team makes us a leading player in this field. Our injection molding capabilities are plastic molding, insert molding, over molding, and family molding.

How long does Your Injection Molding Process Take to Complete?

The time to complete injection molding process generally depend on material availability, design complexity, required surface quality etc. and customer requirements. But generally, it takes 7 – 10 days to complete your project.

What materials can you use in injection molding?

We work with a wide range of injection molding materials, including ABS, polycarbonate, polypropylene, and more specialized resins like PEEK and TPE.

Can you assist with part design for injection molding?

Yes, we offer part design assistance to ensure your designs are optimized for injection molding, focusing on factors like wall thickness, rib design, and gate placement.

What is the minimum order quantity for injection molding?

Our minimum order quantity depends on the specific project. We cater to both small and large-scale production runs, offering flexibility to meet diverse client needs.

Do you offer rapid prototyping for injection molding projects?

Yes, we provide rapid prototyping services to help you validate your designs before moving to full-scale production.

How do you ensure quality in your injection molded parts?

We employ strict quality control measures, including regular inspections and using advanced measurement tools, to ensure each part meets the required specifications.

Can you produce complex and intricate parts with injection molding?

Absolutely. Our advanced injection molding technology allows us to produce parts with complex geometries and intricate details.

What finishing options are available for injection molded parts?

We offer various finishing options, including painting, plating, silk screening, and pad printing, to enhance the appearance and functionality of the parts.

What are the typical tolerances achievable with your injection molding process?

Our injection molding process can achieve tight tolerances, typically within +/- 0.005 inches, depending on the material and part design. We ensure high precision for each part to meet your specific requirements

How do you address undercuts in injection molded parts?

We use advanced techniques like side-actions, lifters, or hand-loaded inserts to effectively manage undercuts in injection molded parts, ensuring complex geometries are accurately produced.