CNC Turning Services

Your Trusted Partner for CNC Turning Services

- High Precision, Accuracy – Machined in 1 Day or Less!

- Client-Centric Solution With Diverse Processing Methods

- Low-Volume, Mass Production, For Prototypes, Production Parts

Certifications: IATF16949:2016 | ISO9001:2015

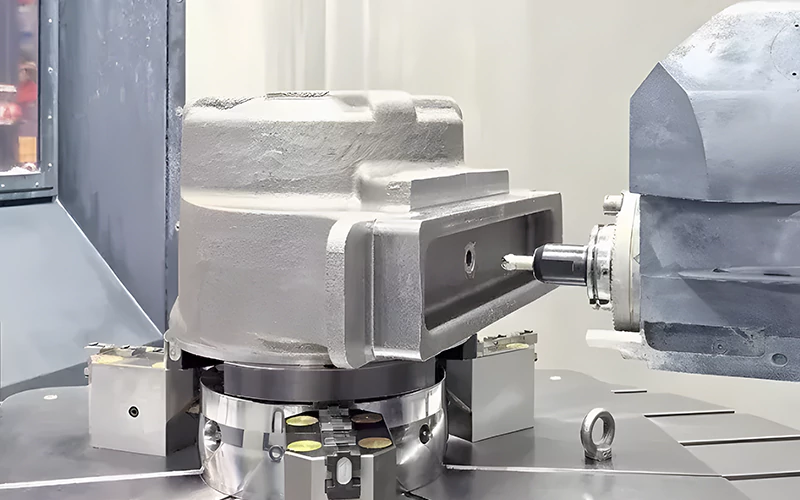

Prototool’s CNC turning services (Lathe machining services) help you get your desired parts, either prototype or production parts developed in a matter of days, hours, and even minutes depending upon the complexity and substance of the part. The process involves rotating the workpiece at high speed in a chuck. Contrary to CNC milling where the tool spins at high speeds, this process rotates the workpiece and the tool moves in accordance with the designing required.

Offering diverse designs with highly market competitive prices, we offer speedy CNC lathe services on the materials of your choice. This includes plastics like polycarbonate, PTFE, PEI, nylon, ABS, POM, PP, PMMA, PEEK and metals like titanium, brass nickel alloy, steel, magnesium, stainless steel copper, etc.

Why Our Turning Services

Pocket-Friendly

Unlike many other providers of lathe machining services, Prototool’s CNC lathe machining is an extremely cost-efficient process ideally suited to high volume production of specialized parts. But we will also guarantee the quality of our products for all our customers at competitive prices.

Ultra-Precise and Accurate

Most projects require precision in the products, and among all these CNC turning is perhaps best suited. The reason is that the machine can approach the workpiece from many directions and turn it in any direction. The part of our CNC turning service team that is most alive involves projects in which high precision and efficiency are required.

Various Turning Materials Options

We understand that no two projects are alike. Where one project may be made using a specific kind of metal, the other may be needed to be made using completely different and dissimilar materials. With the use of our precision CNC lathe machining capabilities, we can delivers a unique combination of functionality and aesthetics to meet your most difficult requirements.

Swift Delivery

Prototool has strict delivery time standards. For different milled parts we have set different levels of lead times, and for simple structures and small quantities required, we can even complete the project in one day. Of course, our sales staff will contact you at any time to get the latest requirements for your project, depending on the priorities of your project.

Steps To Work With Our Turning Services

Request

a Quote

First, get a free quote on our precision CNC turning services. Please give a description and any technical drawings of your product. Not having technical drawings? No problem, our engineers are experts at reverse engineering for CNC lathe machining.

DFM Analysis &

Quotation

You can expect a reply within 24 hours. We'll reply to you with an in-depth Design for Manufacturability (DFM) analysis and a quotation tailored precisely to your CNC turning jobwork services request.

CNC Turning

Begins

After your approval of the quote and deposit, we start work on the project. For precision manufacturing, our team carefully plans out every detail for CNC lathe machining.

Timely

Shipping

CNC-machined parts are carefully packed, labelled and sent directly to you so that they arrive on time. Enjoy the convenience and reliability of our CNC turning solutions.

We Provide the Best Service in Industry

Contact us today and get a free quote to have your work pieces turned.

The Varied CNC Turning Services We Offer

CNC Turning is employed for rapid delivery of highly accurate components, which can either be prototypes or end-users. Moreover, it is used for high volume manufacturing in a variety of processes which include:

Conventional CNC Turning

CNC Turning is traditionally used to make simple medium complex parts with high accuracy. This method will work in both the prototyping phase and when running into mass production where it offers a very flexible being able to machine many different kinds of materials quite precisely.

Multi-Axis CNC Turning

Multi-Axis CNC Turning further expands our range of capabilities in the creation of complex geometries and intricate designs; this system allows us to machine simultaneously from many angles, lowering set up time and increasing overall efficiency as well as precision on parts.

Live Tooling CNC Turning

However, Live Tooling CNC Turning is a type of mill-turn lathe that integrates turning with most any kind of vertical or horizontal machining. We can do several different kinds of cutting all in one setup which shortens production times and allows us to produce very complex parts covering the whole range from curvilinear surfaces through multiplaned plane mirrors right up to some extremely

Hard Turning

Hard Turning is a niche CNC turning process for high hardness materials. It’s an economical substitute to grinding, in which parts with very tight tolerances can be precision machined out of tough metals through this method. This approach becomes particularly suitable when large numbers are being produced as it quickly manufactures long-lasting components using complex standard forms and sections.

Materials used in our CNC turning services

Prototool provides many different materials for CNC lathe machining. We can meet whatever demands you have with respect to your project. Furthermore, we give customers a choice to source custom materials ideal for their application requirements.

Plastics

CNC turning is ideal for the development of prototypes in plastic. It makes for an overall assessment of your product’s appearance and performance from all angles.

Metals

CNC turning is truly king of metal machining. using a variety of metals to make prototypes and finished parts for production, making sure every element is accurate and lasting.

Other Materials

Besides plastics and metals, we provide CNC turning of other alloys as well as specialized materials upon request.

Common Plastics We Work With

ABS, ABS+PC, Polycarbonate (PC), Polypropylene (PP), PEEK, Polyoxymethylene (POM), Acrylic (PMMA), Teflon, Polystyrene (PS), High-Density Polyethylene (HDPE), Polyphenylene Sulfide (PPS), Low-Density Polyethylene (LDPE), Nylon (PA6, PA66), Polyetherimide (PEI), PVC, PET, PTFE

Common Metals We Work With

Aluminum, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc

Non-standard materials Please contact us or request a quotation.

Tolerance Standards

Our CNC turning service offers highly accurate and tightly precise turning. Please note that tolerance is affected by the type of material used along with the geometry of the part that is turned. For more details, consult the chart below:

Tolerance Lever | Overall Dimension Range | ||||||

Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

Tolerance Standard | |||||||

F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Surface Finishes

When we have turned your part with high degree of accuracy and precision, it is time for surface finish which is available in the following options:

As machined (Ra 3.2μm / Ra 126μin)

Smooth machining (Ra 1.6μm / Ra 63μin)

Fine machining (Ra 0.8μm / Ra 32μin)

Polishing (Ra 0.8μm / Ra 32μin)

Bead blasted

Brushed + Anodized type II (Glossy)

As machined + Anodized type II

Chromate Conversion Coating

Black oxide

Electroless Nickel Plating

Bead blasted + Anodized type II (Matte)

Bead Blasted + Anodized type II (Glossy)

Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

As machined + Anodized type III (Hardcoat)

Brushed (Ra 1.2μm / Ra 47μin)

Powder coated

CNC Turning FAQs

EXPLORE ESSENTIAL INFORMATION ABOUT CNC TURNING SERVICES THAT MAY PROVE INVALUABLE TO YOUR NEEDS.

What is the application of your CNC Turning services?

CNC turning is a process similar to CNC milling which is used for designing machine parts that may either be porotypes or ready to be put into mass production. Being one of the most popular processes for custom manufacturing, it can handle irregular geometries requiring axial and radia holes, grooves, and slots, and internal diameters.

What determines the cost of CNC turned parts?

The cost is influenced by factors like material selection, part complexity, precision requirements, and order volume. Our CNC lathe operations are designed to be cost-effective, ensuring you get the best value for high-quality turned parts.

What types of materials can you turn on your CNC machines?

Our CNC turning centers work with a wide array of materials, including but not limited to, various steels, aluminum, brass, copper, titanium, and diverse plastics. This material versatility allows us to meet a broad range of project requirements.

Can you handle high-precision and tight tolerance turning projects?

Absolutely. Our advanced CNC turning services are adept at handling projects requiring high precision and tight tolerances, ensuring each part meets stringent specifications.

Do you offer finishing services for turned parts?

Yes, we provide a range of finishing options for CNC turned components, including anodizing, plating, and polishing, enhancing both the aesthetic and functional qualities of the parts.

How do you ensure quality in CNC turning?

We maintain rigorous quality control in our CNC turning processes, employing precision inspection tools and techniques to ensure every part meets exacting standards.

What type of file formats do you support for CNC machining and CNC turning?

We support a number of file formats to ensure we always meet the requirements of our clients. This includes popular formats of .stp, .sldprt, and .psm/.par. moreover, we make sure to work with our clients to the end so they get their desired result designed to utter perfection. This is the value we stand for.

Is turning a standalone process?

No it is not. CNC turning is a very versatile process that is combined with other processes like casting & 3D printing. Once CNC turning has carved intricate features and details on a part, the part is then sent for mass production and can be put in aforementioned processes for the prototype to be mass produced.

Can you assist with design optimization for CNC turning?

Definitely. Our team offers expert advice on design for manufacturability, optimizing your parts for our CNC lathe machining process to enhance efficiency and reduce costs.

How do you handle urgent or rush CNC turning orders?

Lead times for CNC milling projects vary based on complexity and volume. Generally, we can turn around small projects in a few days, while larger orders may take a few weeks. We always work to meet your deadlines efficiently.

Do you provide assembly services for CNC turned parts?

We offer assembly services as part of our comprehensive CNC machining solutions. After turning, we can assemble your components, providing an end-to-end manufacturing solution from initial concept to final assembly.

How do you handle complex shapes or designs in CNC turning?

Our advanced CNC turning technology, including multi-axis capabilities, allows us to handle complex shapes and intricate designs. We work closely with clients to ensure their specifications are met, regardless of design complexity.