CNC Milling Services

Get Your Custom Parts Now – Fast, Precise Online CNC Milling Services

- 1-10,000 Flexible MOQ

- Tight Tolerance Down To 0.005 mm

- Fast Turnaround In 1 Day Or Less!

Certifications: IATF16949:2016 | ISO9001:2015

Get your rapid prototypes and custom parts with Prototool’s advanced CNC milling and precision machining services. Our 3 and 5-axis CNC milling delivers high-quality parts, from plastics to metals, with tolerances as low as 0.005 mm. Benefit from competitive pricing and fast turnaround, starting from just 1 day. Upload your CAD file for a free quote and manufacturability analysis. Trust us for end-to-end solutions, including material certifications and diverse finishing options, to ensure your parts are perfect.

Why Our Milling Services

Made-to-Order Fabrication

Our CNC milling and precision machining services are all about flexibility and customization. This means you have the freedom to order parts of any complexity, with no minimum quantity requirements and no restrictions on materials. Each client’s order is meticulously managed by our dedicated team, ensuring personalized attention from start to finish. This includes a range of free services such as DFM consultations and material recommendations.

Compliance with Standards Strictly

Our CNC milling and machining services strictly adhere to internationally recognized standards, ensuring the highest quality and reliability for your projects. We are compliant with ISO 9001:2015, ensuring consistent quality management, AS9100D for aerospace quality systems, and IATF16949:2016 for automotive parts. Our adherence to ASTM standards guarantees material quality and performance, while our commitment to ANSI protocols ensures operational safety and precision.

Rapid Turnaround Time

Our rapid milled parts delivery times stem not only from our expert milling processes but also from our streamlined organizational structure. With specialized departments including Sales, Design, Material Procurement, Milling, Quality Control, Warehousing, and Logistics, we ensure a smooth and efficient workflow. When we say we can deliver as quickly as in one day, it’s not just a claim.

Low-cost & High-grade

Balancing cost-effectiveness with high-quality is a fundamental part of our mission. While we may not be the cheapest milling provider in the market, we pride ourselves on offering the most value for your investment. Our commitment to providing affordable yet high-grade CNC machining services is evident in the continuous praise we receive from our clients.

Trusted by Worldwide Partners Including Fortune 500 Company

Steps To Start Your Milling Projects

1. Submit Request

Initiate your project by submitting a detailed request for CNC milling services. Provide comprehensive information including CAD designs, material specifications, and specific requirements for your custom CNC milling project.

2. DFM & Receive Quotation

After your precision milling inquiry, we will conduct a DFM analysis, crucial for ensuring efficient and effective CNC milling. Following this, you'll receive a detailed quotation for the proposed computer-aided milling services, reflecting the cost and scope of your project.

3. Custom Milling Process

This stage involves the actual production process, where your parts are created using advanced CNC milling techniques. If your project requires, surface finishing will be after the precision machining process.

4. Quality Control & Final Inspection

Prior to shipping, a rigorous quality control and final inspection are conducted. This step is integral to ensure that all parts produced through our CNC manufacturing services meet the highest standards of precision and quality.

CNC Milling Experts at your service

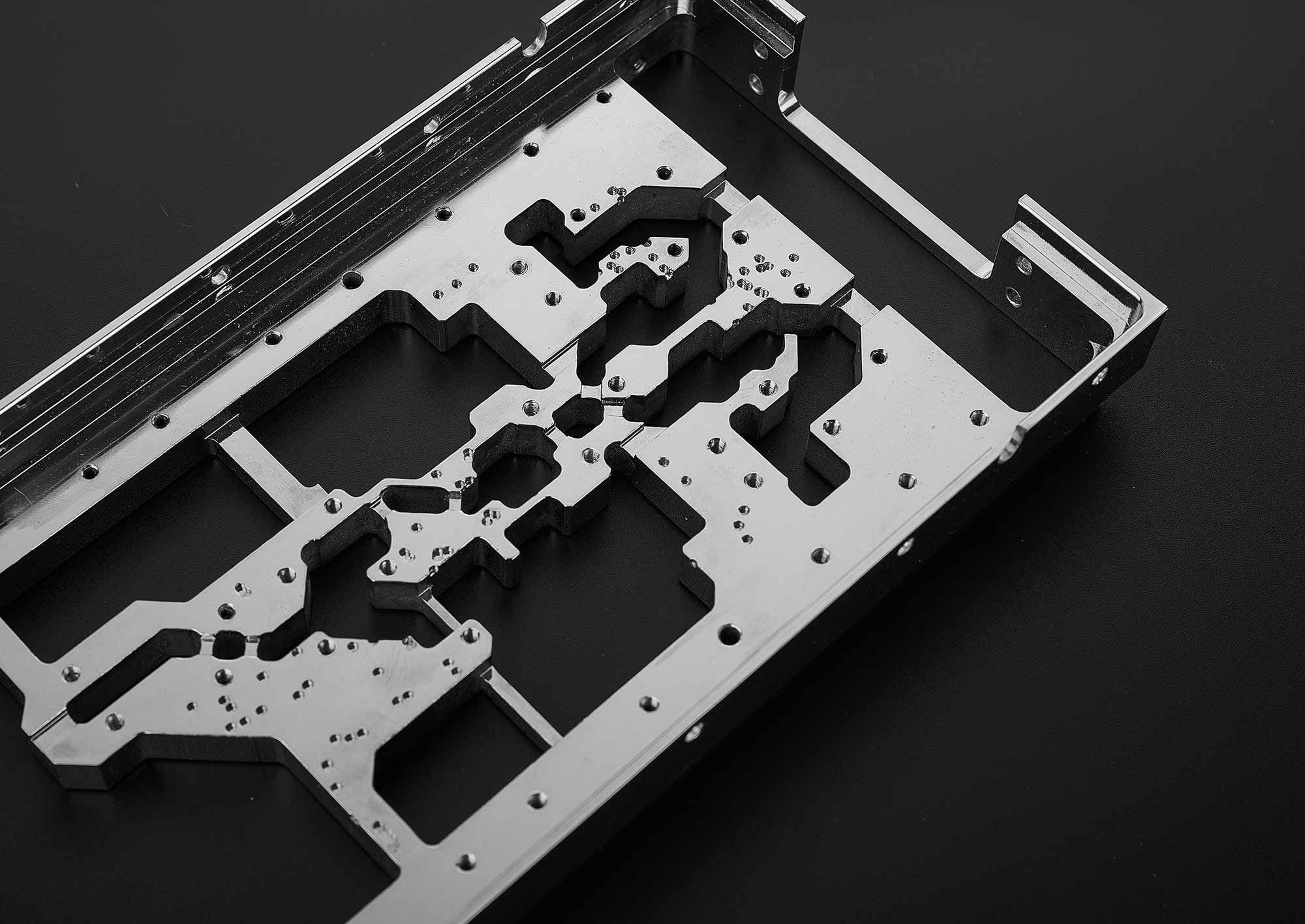

What We Can Do

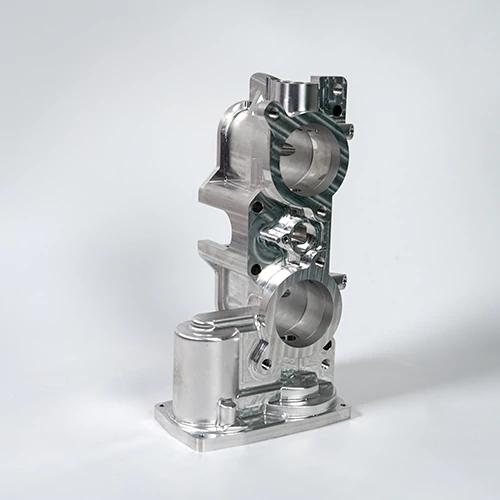

Prototool's CNC milling services extend far beyond what you might imagine, capable of machining a vast array of parts and products across virtually every industry. Our precision milling expertise brings your most complex designs to life, no matter the sector.

Prototypes

With our advanced CNC machining services, we specialize in creating accurate and high-quality prototypes. Our precision milling processes are perfect for both one-off prototypes and small batch production.

Medical Parts

In medical manufacturing, our CNC milling services are invaluable. We produce complex, high-precision components essential for medical devices and implants.

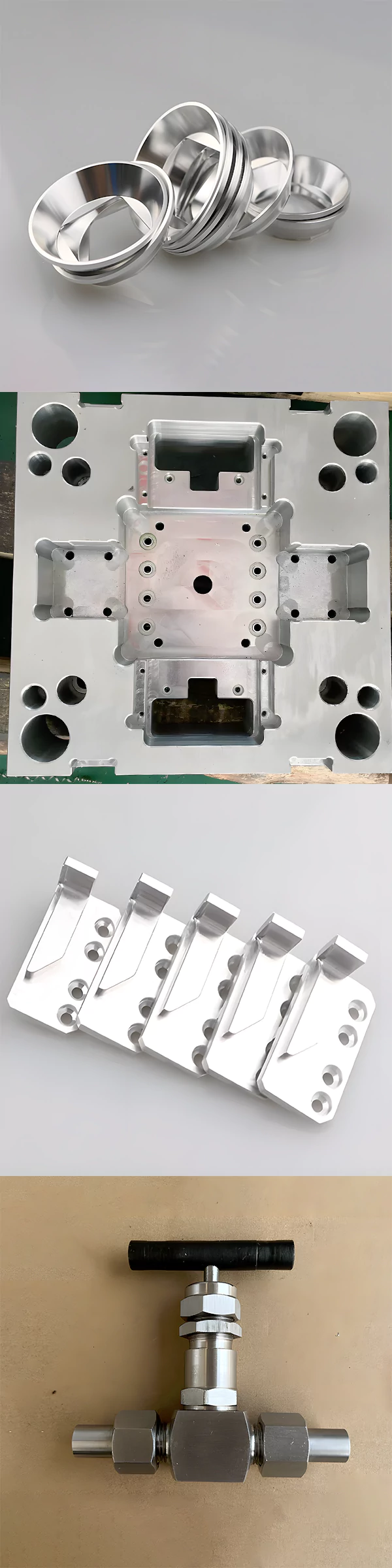

Mold Components

For tooling and molding applications, our computer-aided milling services provide the high level of precision required for intricate mold components. We excel in handling complex shapes and fine details, crucial for producing high-quality molds for casting and injection molding processes.

Plastic & Metal Valves

Valves are difficult components that have intricate geometry, which is why they are difficult to be milled very accurately. With our highly proficient team of engineers, we can make valves with out of any material with out 3-5 axis CNC milling service.

The Milling Materials We Specialize In

Among a variety of materials that we offer our customers and work with, we also offer our customer the option to source material for them from the market that will fit their desired application.

Plastic

A highly preferred way to develop prototypes is to have your product milled in plastic. Not only it will allow you to review your product from all angles, but also allow you to test its design and functionality.

Metal

Milling Metals is where CNC milling shines the brightest. There are a variety of metals that can be milled to develop prototypes as well as develop end-user parts to put into manufacturing.

Other Materials

Aside from plastics and metals, CNC milling is used to Mill a variety of allows and other custom materials as per you requested.

Common Plastics We Work With

ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE.

Common Metals We Work With

Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc

If your desired material is not listed above, contact us and order a free quote today!

Our Milling Tolerance Standard

Our CNC milling service offers highly accurate and tightly precise milling. Please note that tolerance is affected by the type of material used along with the geometry of the part that is milled. For more details, consult the GB/T1804-2000(mm) below:

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

In the default state, the products or parts we machine for customers are executed at the F level. In fact, this standard is not sufficient to reflect our strong machining capabilities, as we can control the minimum tolerance to 0.005mm.

Finishing For Milled Parts

When we have milled your part with high degree of accuracy and precision, it is time for surface finish which is aviable in the following options:

As machined (Ra 3.2μm / Ra 126μin)

Smooth machining (Ra 1.6μm / Ra 63μin)

Fine machining (Ra 0.8μm / Ra 32μin)

Polishing (Ra 0.8μm / Ra 32μin)

Bead blasted

Brushed + Anodized type II (Glossy)

As machined + Anodized type II

Chromate Conversion Coating

Black oxide

Electroless Nickel Plating

Bead blasted + Anodized type II (Matte)

Bead Blasted + Anodized type II (Glossy)

Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

As machined + Anodized type III (Hardcoat)

Brushed (Ra 1.2μm / Ra 47μin)

Powder coated

CNC Milling FAQs

You might discover valuable insights regarding CNC milling services that could be beneficial for you

What industries commonly use your CNC milling services?

Our precision CNC machining and milling services cater to a wide range of industries, including aerospace, automotive, medical, and electronics, sports goods, cosmetics, etc. Our advanced milling technology is versatile enough to meet the diverse needs of these sectors.

What are the precision and tolerance capabilities of your CNC milling machines?

Our state-of-the-art CNC milling equipment can achieve high precision and tight tolerances, typically within +/- 0.005 mm. This precision is crucial for complex and detailed parts, ensuring they meet exact specifications.

Can you handle both small and large volume orders in CNC milling?

Absolutely. Our flexible CNC machining operations are equipped to handle orders of any size, from prototype batches to large-scale production runs, without compromising on quality or efficiency.

What types of CNC milling machines do you use?

We utilize a variety of advanced CNC milling machines, including 3-axis, 4-axis, and 5-axis milling centers. This range allows us to perform precision machining for a wide array of part geometries and sizes, ensuring high-quality results for every project.

How do you handle urgent or expedited CNC milling requests?

For urgent CNC machining needs, we offer expedited services. Our efficient workflow and flexible milling operations allow us to prioritize and fast-track projects while maintaining our high standards of quality and precision.

Can you assist with the design and optimization of parts for CNC milling?

Yes, our team can provide design assistance and optimization services. We offer expert advice on how to adapt your designs for optimal CNC milling efficiency and cost-effectiveness, ensuring your parts are machined in the most effective manner.

Do you offer assembly services for CNC milled components?

Yes, we provide assembly services as part of our comprehensive CNC machining solutions. After milling, we can assemble your components, offering a complete manufacturing solution from initial concept to final assembly.

What post-processing services do you offer for CNC milled parts?

We offer a range of post-processing services, including anodizing, painting, and plating, to enhance the appearance and functionality of CNC milled parts, ensuring they meet your final application requirements.

How do you manage and protect intellectual property for custom CNC milling projects?

Protecting your intellectual property is a top priority. We adhere to strict confidentiality agreements and ensure that all custom CNC machining projects are handled with the utmost discretion and security.

What are the typical lead times for CNC milling projects?

Lead times for CNC milling projects vary based on complexity and volume. Generally, we can turn around small projects in a few days, while larger orders may take a few weeks. We always work to meet your deadlines efficiently.

Can you mill parts from solid blocks or do they need to be pre-formed?

We can mill parts directly from solid blocks of material, offering greater design flexibility and material integrity. Pre-formed materials can also be used depending on the project requirements.

Can you work with customer-supplied materials for CNC milling?

Yes, we can work with materials supplied by customers, provided they are suitable for CNC milling and meet our quality standards.