custom precision parts manufacturing Services

We offer a wide range of processing methods for metal and plastic parts

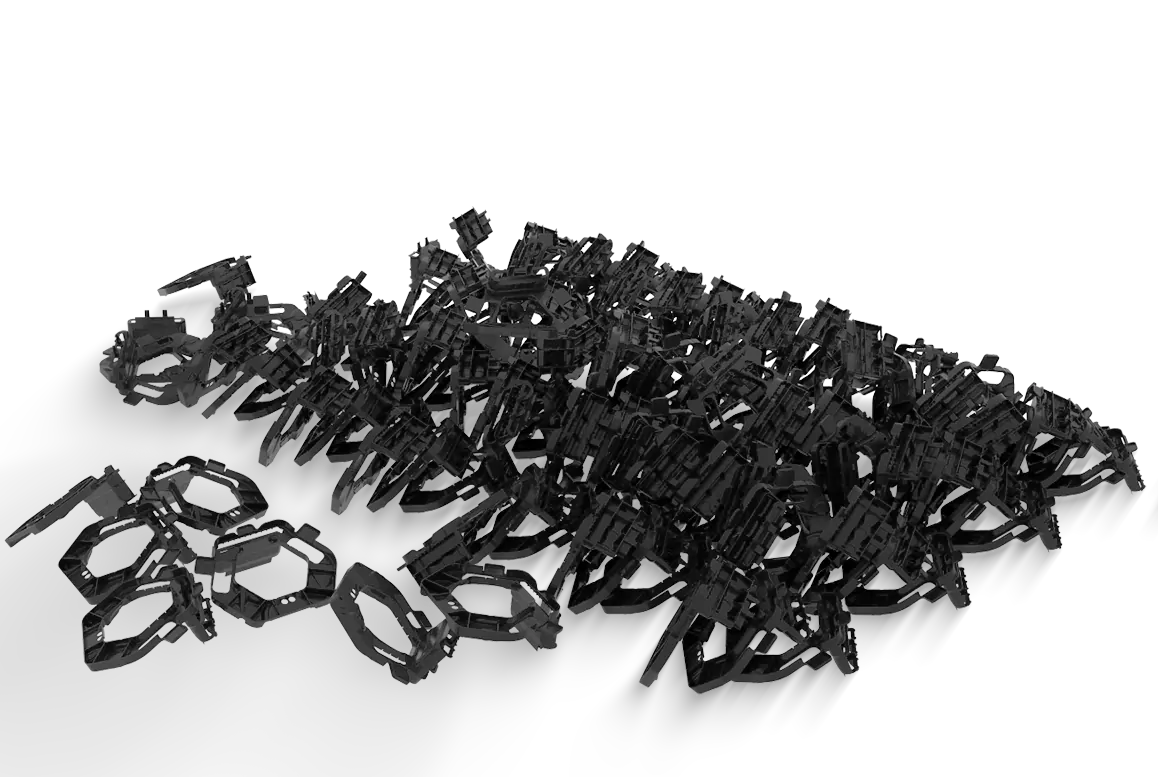

- Injection Molding

- Mold Making

- Rapid Prototyping

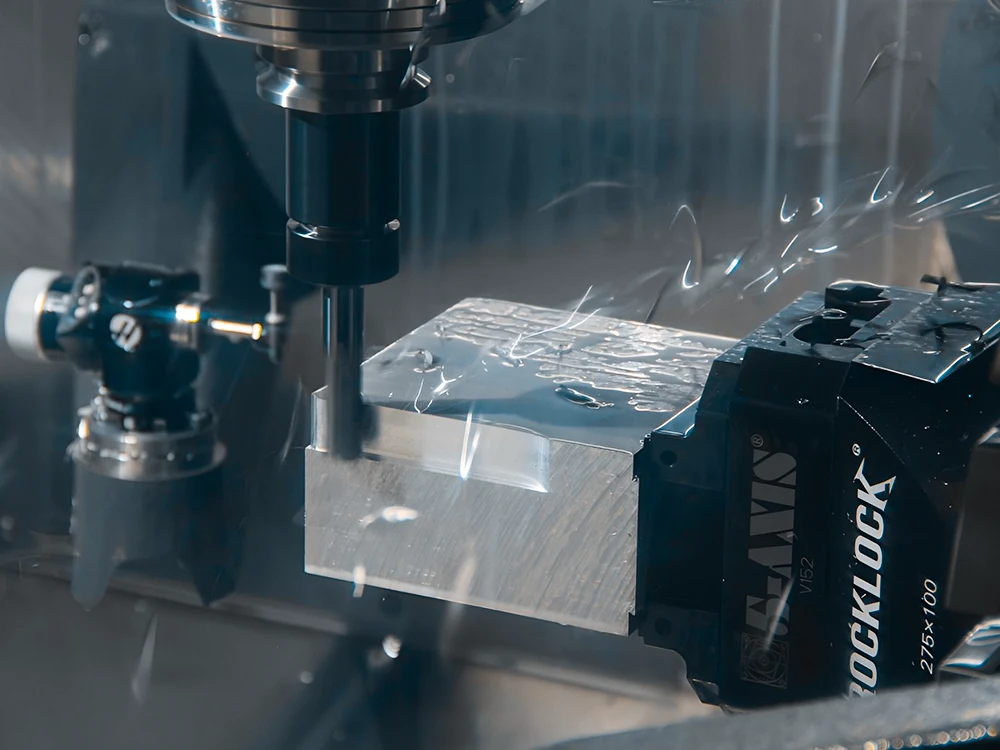

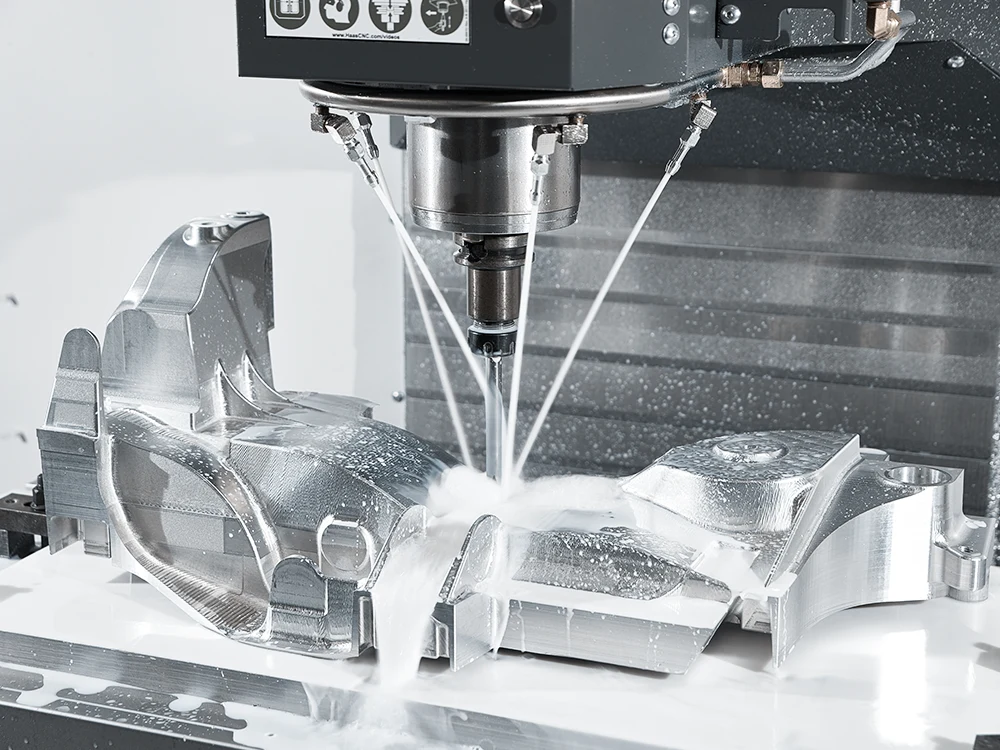

- CNC Machining

- Die Casting

- Vacuum Casting

Prototool started through rapid prototyping services and injection molding services. We have developed into a famous plastic & metal parts manufacturing manufacturer in China in more than ten years. Prototool has a wealth of part machining means (such as plastic injection molding, mold making, rapid prototype, CNC machining, die casting, 3D printing, etc.). We have experiences in the automotive, medical industry to meet your various part machining and production needs, no matter in small-batch or mass production.

What Our Parts Manufacturing Services Offer

Our wide range of form of components manufacturing services can be categorized into two types

Low-volume Manufacturing

Low-volume manufacturing makes use of rapid prototyping services, 3D printing services, CNC machining services and vacuum casting services.

After obtaining the 3D CAD data file for the manufactured parts,, improvements are made and the technique best suited for the demand of parts needed would be analyzed and applied.

Mass production

Our cutting-edge technology offers you a wide range of options for creating your dream machined plastic products or manufactured metal parts. Whether you require advanced, injection molding, mold making, or die casting processes, Prototool has got you covered.

We pride ourselves on delivering exceptional functionality, stunning appearance, and precise dimensions to bring your vision to life.

Advanced Parts Manufacturing Techniques

Multiple professional parts manufacturing or components fabrication technologies are made use of at Prototool which provides technologically advanced solutions for your business. These include:

Choose Your Right Manufacturing Supplier

In this competitive market, it is imperative that you choose the best parts production services for your business as these parts will be the foundation behind its success.

Flexible Production Capability

At Prototool, you can choose from a diverse range of materials, markings, finishings, etc., which are purely catered to your requirements.

Smooth sailing shipping and delivery

Your orders will be delivered directly to your door and help you avoid the entire hassle of shipping and delivery.

Professionals on the job

We have a certified network of a reliable, trusted, and skilled team of experts who ensure to provide you with exactly what you need.

Premium quality and supreme techniques

Only the best, technologically advanced techniques are used along with premium quality materials for your machine parts.

How To Work With Us

Request a matchless quote

Make a quote request by providing a few basic details and a description of your project along with the part number, material choice, finishing type, and quantity of parts you require.

Refine and approve your selection

Once we send you the best, most reasonable quote back and you approve, we can proceed with the specifics of building your dream parts.

Diving into the big launch

After you make the deposit, manufacturing will commence, keeping you updated every step of the day.

Instant delivery to your doorstep

It ends in the result being shipped and delivered to you as soon as the parts are ready to go.

We Provide the Best Service in Industry

Helping you achieve your ideal prototyping, manufacturing, and production parts specifically catered to your business; Prototool promises to help your business grow in no time!

Our Happy Clients!

Material We Used

Prototool offers a remarkable variety of materials for your parts depending on your needs. We have the best quality of plastic (ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, etc.) available. In terms of metal parts, we offer premium quality Aluminum, Copper, Titanium, Brass, Tin, Zinc, Stainless Steel, Magnesium, and more. These are the most common materials used and if your business is in search of any other materials, we can arrange them as well for you.

Industry Applications

Prototool strongly values the importance of economic growth and industrial enrichment. With the quality parts that we offer to produce and deliver, these can be well suited and built for a wide range of industries such as automotive or aerospace industries. The electronics and robotics industries also are one of our best demanding industries. Prototool manufacturing has also expanded to medical, dental, and educational industries as well as energy-producing industries that are always in need of effective, durable, and reliable mechanical parts.