Rapid Prototyping services

Market entry testing with rapid prototyping services

- Your Partner for Reliable Rapid Prototyping Services

- Over 12 years and 2000 types of metal and plastic parts processed

Our rapid prototyping services provide clients with high-quality product and machine prototypes. We use a variety of techniques and materials tailored to your needs. With our expertise, you can ensure efficient and precise prototyping.

Why Choose Prototool

Here are some core values of the rapid prototyping that you’ll have in our service.

International level expertise

We have a team of experts with 12 years of experience in providing manufacturing services at the international level. They can offer top-notch services to you in rapid prototyping.

Affordable pricing

Are you worried about the budget for rapid prototyping? You don't have to worry as we'll provide the services at an affordable price. We offer a competitive cost that is worth the offer we are providing.

Easy to use

With our service, you'll get delivery fast, right after your door. You'll get your products with no difficulty or hassle.

Unlimited options

Rapid prototyping provides you with a lot of different options for your order. You can have access to these while you place the order. These include material, tolerance, finishing, and markings.

Our Working Process

Here is the typical working order to expect when you hire us for our die casting services:

Submit Request

Submit your free quote request with a description and technical drawing of your product. In case of no technical drawing, no worries. We can reverse engineer.

DFM & Quotation

We usually get back to you within 24 hours.

Prototyping

Once you approve the quote and make the deposit, we'll use the latest equipment and materials to start the work that accurately reflects the design.

Refinement

We'll thoroughly test the prototype to ensure it meets your specifications. Based on your feedback and testing results, we'll make any necessary adjustments.

Call us for the best rapid prototyping service now

Machining Method For Rapid Prototyping

We mainly use two methods frequently according to the requirements of our products.

1

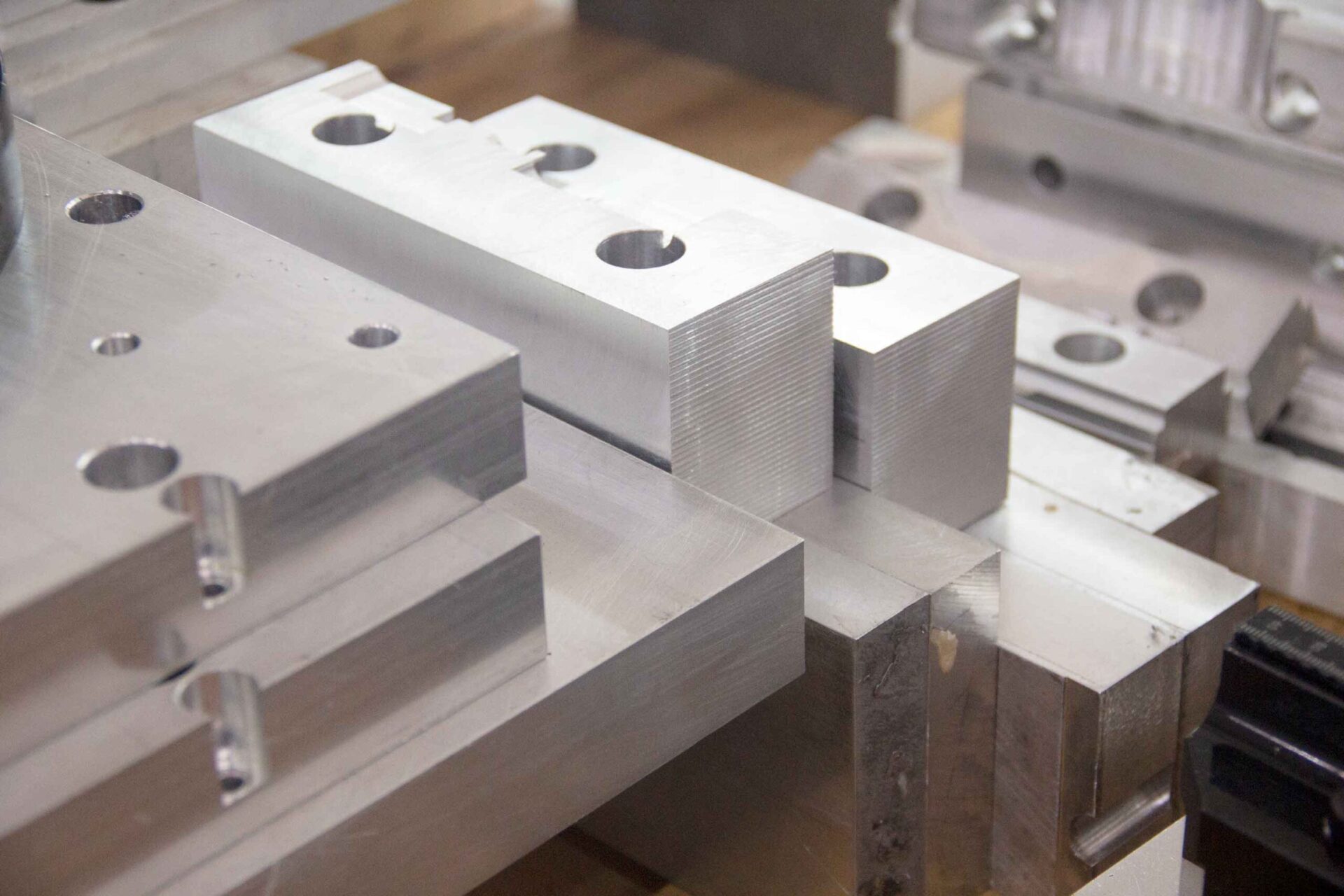

CNC MACHING RP

It offers fast processing speeds, low costs, and high processing accuracy. With a wide range of material selection, they can ensure consistency between the material of the hand-made model and the material of the mass-produced parts.

2

VACUUM CASTING PROTOTYPE

It uses liquid PU as its material, which offers characteristics similar to ABS, PC, and other plastics. This process is ideal for small quantities of about 10-100 sets of plastic products and is cost-effective with a shorter production cycle.

Rapid Prototyping in a Variety of Materials

Once exporting your rapid prototypes, it is necessary to seek a reputable fast prototyping company that can manage a variety of materials and be able to preserve the entire immediate prototyping project in one area. In this regard, we are an excellent choice. We can create prototype parts out of plastics, metals, and ceramics.

Plastics

We offer a wide range of plastic materials for rapid prototyping, including ABS, PC, PMMA, PA, POM, PP, and more. Our team has extensive experience in selecting the right material for each project, ensuring the best performance and cost-effectiveness for your prototypes.

Metals

We offer a variety of metal materials for rapid prototyping, including aluminum, stainless steel, brass, copper, and more. Each metal material has its own unique properties, such as strength, ductility, and thermal conductivity, allowing us to create parts with different functional requirements.

Tolerance for Our Rapid Prototyping

Straightness: Tolerance levels can range from 0.05 mm to 0.5 mm, depending on the length of the feature and the technology used.

Flatness: Tolerance levels can range from 0.05 mm to 0.5 mm, depending on the size of the feature and the technology used.

Roundness: Tolerance levels can range from 0.05 mm to 0.5 mm, depending on the diameter of the feature and the technology used.

Cylindricity: Tolerance levels can range from 0.05 mm to 0.5 mm, depending on the diameter and length of the feature and the technology used.

Surface Treatment

- Painting

- Plating

- Anodizing

- Sandblasting

- Powder coating

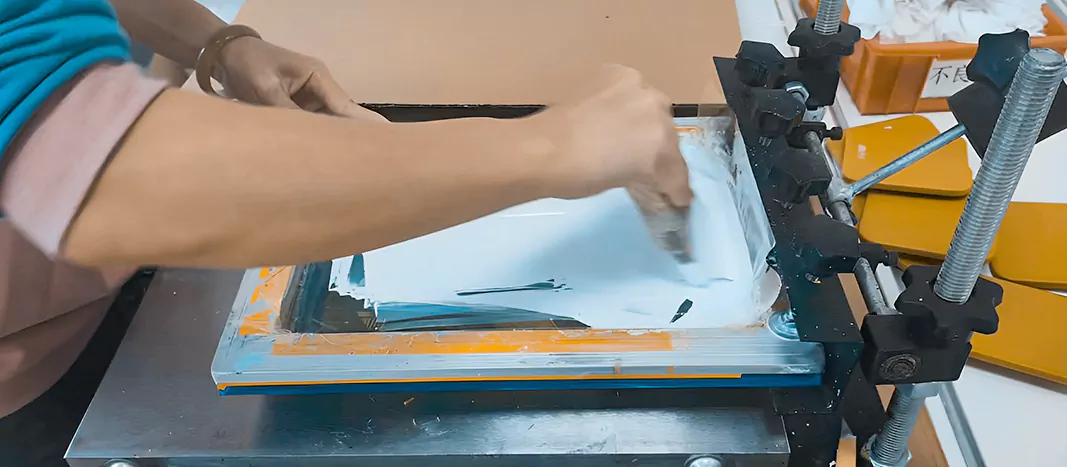

- Screen Printing

Automotive | Aerospace | Medical | Consumer Electronic | Industry Equipment |

|---|---|---|---|---|

Engine Components | Turbine Blades | Prosthetics | Phone Cases | Gears |

Dashboard Prototypes | Structural Components | Surgical Guides | Laptop Casings | Valves |

Light Housings | Prototype Engine Parts | Dental Implants | Keypads | Conveyor Systems |

Air Ducts | Orthotics | Speaker Grilles | Pump Parts |

Galleries

Rapid Prototyping Services FAQs

information about RAPID PROTOTYPING Services for Your projects

How quickly can I receive a prototype using your rapid prototyping services?

Our quick-turn prototyping typically delivers parts within a few days, depending on the complexity and the chosen method. 3D printing can often produce parts within 24-48 hours, while CNC machining might take a few additional days.

What information do you need to provide a quote for fast prototyping?

For a quote on accelerated prototype creation, please provide detailed 3D CAD files, material specifications, and any specific finishing requirements. The more detailed your information, the more accurate our quote will be.

Can you produce functional prototypes that mimic final product materials?

Yes, with our advanced prototyping techniques, we can create functional prototypes using materials that closely resemble those in the final product, especially in CNC machining.

What is the maximum size you can handle for prototype fabrication?

The maximum size for prototype fabrication depends on the chosen method. For 3D printing, it’s limited by the printer size, while CNC machining can accommodate larger sizes. Please provide specific dimensions for a precise answer.

Are your rapid prototyping services suitable for complex geometries?

Absolutely. Our express prototyping, particularly 3D printing, excels at producing complex geometries that might be challenging or impossible to achieve with traditional manufacturing.

Can I make design changes after seeing the initial prototype?

Yes, one of the benefits of our quick prototyping services is the ability to make design changes after reviewing the initial prototype. We can rapidly iterate to refine the design.

How does the cost of rapid prototyping compare to traditional manufacturing?

Rapid prototyping can be more cost-effective for small quantities as it eliminates the need for expensive tooling and setup costs associated with traditional manufacturing.

Can rapid prototyping be used for stress and load testing?

Yes, we can produce prototypes using materials that are suitable for stress and load testing, especially with CNC machining, which can use a wide range of durable materials.

What is the level of detail that can be achieved with your prototyping methods?

Our advanced prototyping methods, especially high-resolution 3D printing, can achieve fine details and complex features, suitable for intricate designs and applications.

What file formats are required for CNC and 3D printing prototyping?

We commonly accept CAD file formats such as STL, STEP, and IGES for both CNC and 3D printing prototyping.

How do you determine the best prototyping method for my project?

We evaluate factors such as the complexity of the design, material requirements, desired finish, and intended use of the prototype to recommend the best method, be it CNC machining, 3D printing, or a combination.

Can you scale up from prototyping to full production?

Yes, we can assist in scaling up from prototype to full production. We provide insights and support in transitioning your project for mass manufacturing.