CNC Machining Service

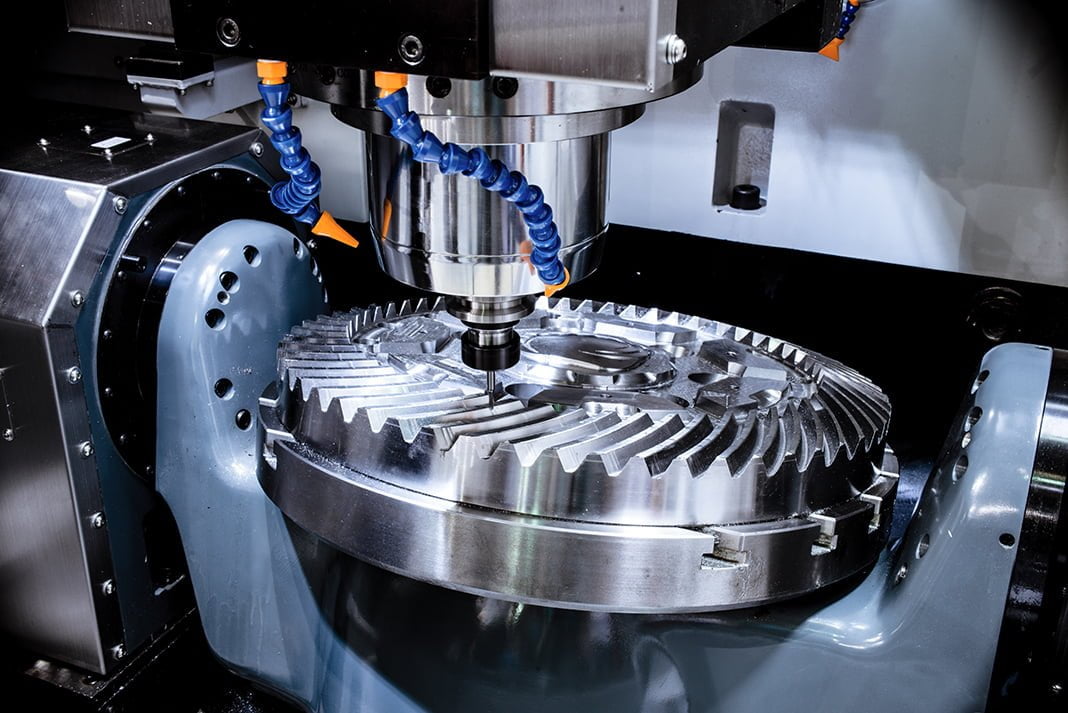

Custom CNC machining services, 4 axis and 5 axis capabilities, specializing in rapid CNC prototypes and on-demand production.

- Quick Turn-around As Fast As 1 Day

- Tight Tolerance Down To 0.01mm

Certifications: IATF16949:2016 | ISO9001:2015

Prototool provides precision CNC manufacturing services. We have many types of high-precision machining equipment: 5-axis CNC machining centers, 4-axis CNC machining centers, high-precision centers, etc. Our machining shop has more than ten years of experience in engine blocks, automotive parts, cylinder heads, rotary shafts, drive shafts, gears, gearboxes, brake drums, hubs, gear rocker arms, rocker shafts, jet engine parts, medical device components, etc. We’re proud of the constant pursuit of speed, precision, versatility, and service by all our employees.

Why Choose Us

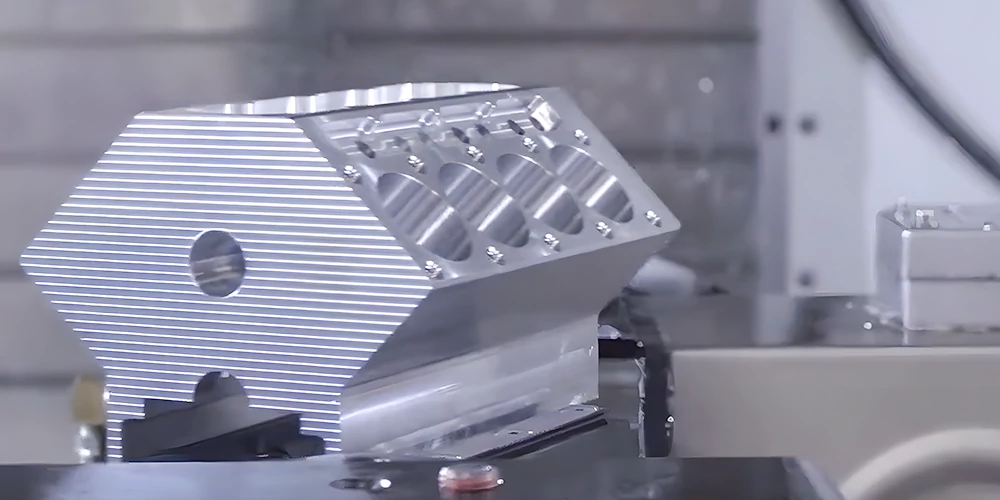

Multiple Branded Equipment

Our workshop is outfitted with an array of high-performance, brand-name CNC machinery, including notable brands like Haas, GF+, Mazak, etc. Our comprehensive suite of CNC equipment encompasses a variety of types, such as 5-axis and 4-axis machining centers, along with advanced precision machining tools.

Rapid Turnaround Times

Prototool’s expert precision machining team and streamlined workflow, backed by over ten years of diverse project experience, ensure swift and accurate completion of your orders. Our setup is optimized for rapid, high-quality custom machining services, guaranteeing on-time delivery for every project.

High Precision and Quality

With our advanced CNC fabrication tools and our team’s deep understanding of precision engineering, Prototool consistently delivers exceptional accuracy in every project, maintaining tolerances as tight as +0.01 to +0.02mm. This commitment to precision ensures the highest quality in all our CNC machining services.

Cost-Efficient Manufacturing

Prototool goes beyond competitive pricing in CNC machining. We work closely with clients, offering expert design and material advice to optimize product performance. This approach ensures cost-effective, high-quality custom machining solutions, delivering great value for your investment.

Precision Without Borders

At Prototool, our dual-base CNC machining hubs in China and Mexico deliver unmatched agility for high-tolerance metal and plastic parts. Whether you need prototypes tomorrow or scaled production next month, we turn complexity into certainty—globally compliant, locally competitive.

Speed Redefined:

- Rapid Turnaround: 3-5 days for prototypes (aluminum/plastics), 10-12 days for hardened steel production parts.

- 24/7 Capacity: Mexico facility operates 3 shifts to meet urgent OEM demands.

Tariff-Optimized Sourcing:

- China: Cost-efficient, large-volume production for Asian and European markets.

- Mexico: Duty-free access to North America via USMCA, slashing your landed costs by up to 25%.

Precision Guaranteed:

- ±0.005mm tolerances with 5-axis CNC, CMM inspection, and ISO 9001-certified workflows.

- Materials mastery: aerospace alloys (Ti6Al4V, Inconel), medical-grade stainless steel, engineering plastics (PEEK, Ultem).

Steps to Engage with Our CNC Machining Experts

Submit Request

Start by submitting your free quote request, complete with product descriptions and technical drawings. If you don’t have a technical drawing, our precision machining team can assist with reverse engineering.

DFM & Quotation

Our custom machining experts will review your request and provide a detailed quotation, typically within 24 hours, ensuring a swift response for your CNC machining needs.

Machining Process

Upon quote approval and deposit receipt, we initiate the project. This involves preparing our advanced CNC machinery and beginning the precision fabrication process, tailored to your specifications.

Shipping

Your CNC machined products are carefully packaged, labeled, and shipped directly to your doorstep, ensuring timely and safe delivery.

Highest quality, Quickest turn-around

CNC Machining Service Options

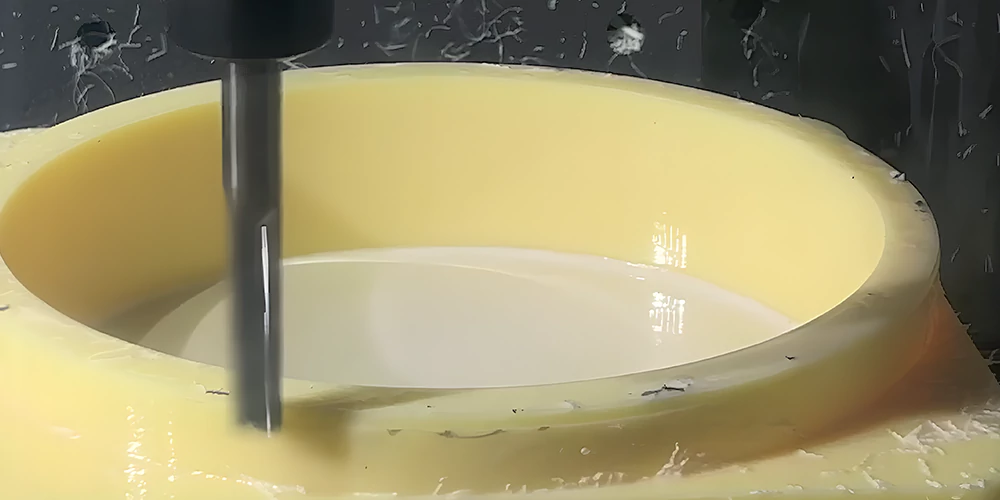

CNC Milling Service

Specializing in complex geometries and precision parts, our CNC milling process is ideal for components like engine parts, frames, and enclosures. We deliver features with exceptional accuracy and surface finish using advanced milling machines.

CNC Turning Service

Perfect for cylindrical parts such as shafts, rods, and bushings, our CNC turning ensures high precision and excellent surface integrity. Our turning centers are adept at handling various materials, producing parts with tight tolerances and smooth finishes.

Materials Expertly Machined by Our CNC Services

In our CNC fabrication services, we handle a diverse range of materials, catering to our customers’ specific needs. Additionally, we offer the convenience of sourcing the perfect material from the market to match their application requirements.

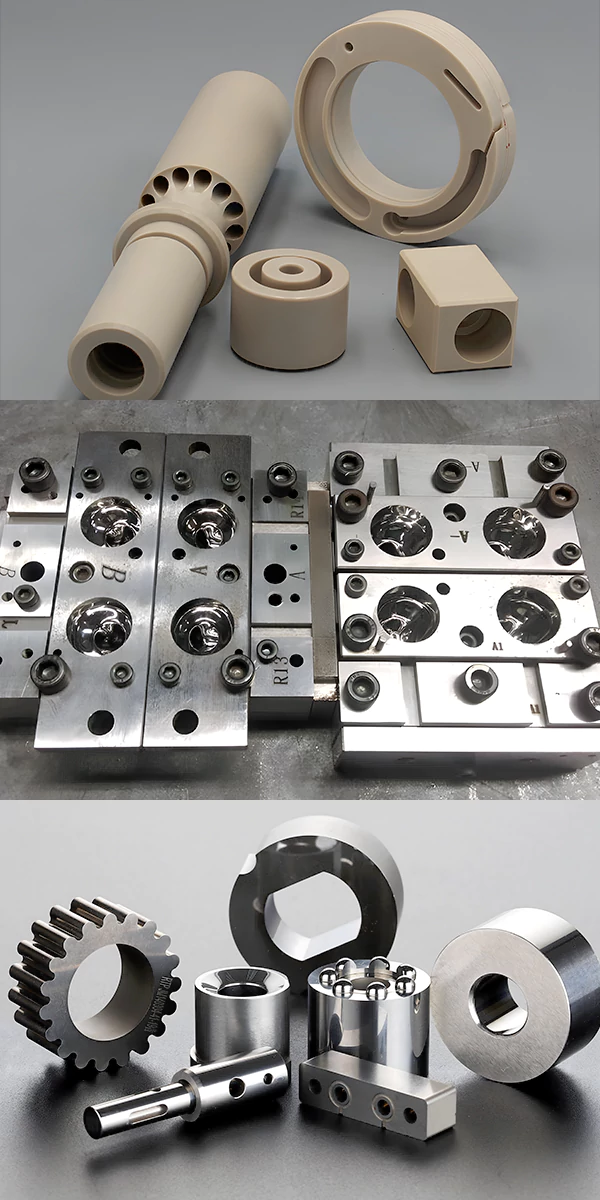

Plastic: Utilizing our precision CNC machining capabilities, plastic is a popular choice for developing prototypes. This process allows for a comprehensive evaluation of your product, enabling you to assess its design and functionality thoroughly.

Metal: The versatility of our CNC machining services is most evident when working with metals. We can machine a variety of metals, ideal for both prototype development and creating final parts for manufacturing.

Other Materials: Beyond plastics and metals, our custom CNC machining solutions extend to a wide array of alloys and other specialized materials, as per our clients’ requests.

Common Plastics We Work With

ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE.

Common Metals We Work With

Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc

If your desired material is not listed above, contact us and order a free quote today!

Prototool's CNC Machining Tolerance Standards

Our CNC milling service offers highly accurate and tightly precise milling with tolerance as tight as 0.01 – 0.05mm. Please note that tolerance is affected by the type of material used along with the geometry of the part that is milled. For more details, consult the chart below:

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Surface Finishes of CNC Machined Parts

As machined (Ra 3.2μm / Ra 126μin)

Smooth machining (Ra 1.6μm / Ra 63μin)

Fine machining (Ra 0.8μm / Ra 32μin)

Polishing (Ra 0.8μm / Ra 32μin)

Bead blasted

Brushed + Anodized type II (Glossy)

As machined + Anodized type II

Chromate Conversion Coating

Black oxide

Electroless Nickel Plating

Bead blasted + Anodized type II (Matte)

Bead Blasted + Anodized type II (Glossy)

Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

As machined + Anodized type III (Hardcoat)

Brushed (Ra 1.2μm / Ra 47μin)

Powder coated

Our CNC Machining Applications

For Mold and Die Making

CNC Machining is pivotal in developing various molds, including plastic injection molds, high-pressure die-cast molds, two-shot molds, 2 plate molds, and 3 plate molds. Owing to their exceptional precision, our CNC machines can carve molds in the desired metal swiftly, making them highly preferred for rapid tooling or production tooling. This capability ensures that we can meet diverse and complex tooling needs efficiently, aligning perfectly with the demands of rapid manufacturing.

In our CNC machining services, we can fabricate custom prototypes for a variety of sectors, such as detailed automotive parts like engine components, intricate medical devices like prosthetics, and consumer electronics like smartphone cases. Our precision machining ensures these prototypes are accurate representations of the final products, ideal for testing and validation. CNC machining is cost-effective and efficient, enabling quick, precise prototyping at all stages.

We specialize in manufacturing various aerospace components, including turbine blades, engine mounts, landing gear parts, and aircraft structural elements. Our advanced machining capabilities also extend to producing intricate fittings, control system components, and aerofoil sections. Each part is meticulously crafted to meet the stringent standards of the aerospace sector, ensuring optimal performance and safety.

We specialize in creating components such as engine blocks, transmission gears, suspension systems, and steering mechanisms. Our precision machining also allows for the production of custom exhaust systems, brake components, and intricate valve assemblies. Each automotive part is engineered to withstand the rigors of daily use, ensuring reliability and performance in every vehicle.

We expertly craft components such as orthopedic implants, surgical instruments, and diagnostic equipment casings. Our capabilities also extend to machining complex parts for medical imaging devices, dental tools, and custom prosthetics. Each piece is manufactured with the utmost precision and care, adhering to strict medical standards to ensure safety and efficacy in healthcare applications.

We skillfully produce components for household appliances, sports equipment like bicycle parts, and musical instrument pieces. Additionally, our machining expertise extends to creating detailed parts for personal gadgets, luxury goods, sports goods, toys, kitchenware, and even custom furniture fittings. Each product benefits from the precision and quality assurance that CNC machining brings.

Understanding CNC Machining

If you're new to CNC machining services, here's a quick primer to get you started:

What's CNC Machining

CNC Machining, short for Computer Numerical Control Machining, is a way to make parts using computers to control machine tools. It’s known for:

- Precision: It makes parts very accurately.

- Efficiency: It’s fast and can make complex shapes easily.

- Versatility: Used for everything from cars to chairs and boats.

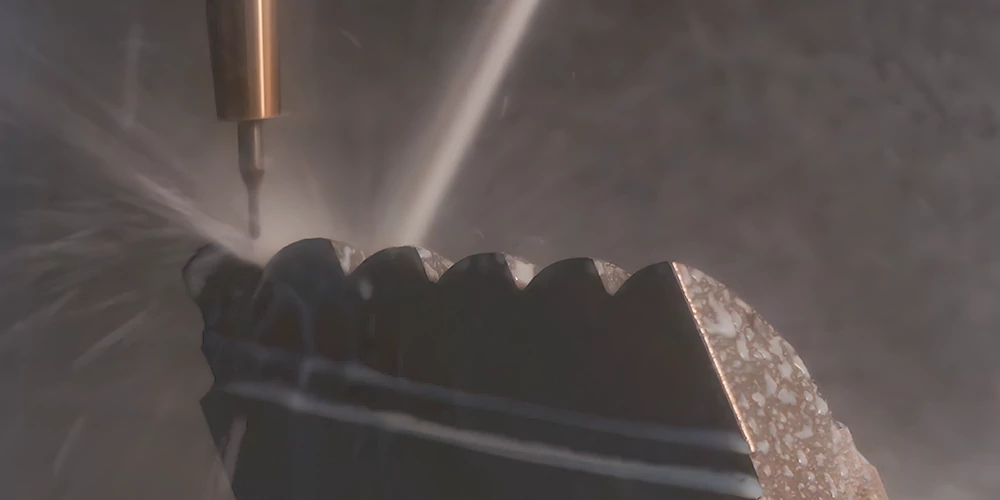

How CNC Machining Works:

- Plan the Part: We look at the design and figure out the best way to make it.

- Set Up the Machine: We program the machine with the right instructions.

- Machining: The machine precisely cuts and shapes the material.

- Check Quality: We make sure each part is perfect.

More Information about “What’s CNC Machining“

Why Choosing CNC Machining

CNC machining stands out for several key reasons:

Unmatched Accuracy: It’s incredibly precise, making it a top choice for critical industries like aerospace and medical devices.

Speed and Versatility: Whether it’s a prototype, final product, or a mold, CNC machining works quickly and can handle complex designs with ease.

Safety and Reliability: The process minimizes human error, ensuring consistent quality and safety.

Wide Material Compatibility: CNC machining is adaptable, working with a range of materials to meet various industry needs.

Efficiency for Manufacturers: It requires low maintenance and can operate continuously, making it a cost-effective solution.

Ideal for Complex Tasks: From milling to turning, CNC machining is perfect for intricate designs and non-conventional machining tasks.

CNC Machining FAQs

Perhaps you can find some useful information about CNC machining services for you here

What is the application of CNC Machining?

CNC machining is a process which is used for designing machine parts that may either be porotypes or ready to be put into mass production. Being one of the most popular processes for custom manufacturing, it can handle irregular geometries of intricate parts and even used to produce for mass production of parts once a prototype is approved.

What type of file formats do you support for CNC machining ?

We support a number of file formats to ensure we always meet the requirements of our clients. This includes popular formats of .stp, .sldprt, and .psm/.par. Moreover, we make sure to work with our clients to the end so they get their desired result designed to utter perfection. This is the value we stand for.

What kind of equipment do you have available?

At Prototool, not only do we have 3 axis and 4 axis CNC milling, but we also have 5 axis(HAAS) CNC milling services. All of these services provide excellent results except when you need finer quality results, we suggest 5-axis CNC milling service instead of 3 axis or 4 axis milling services. Moreover, our CNC turning service employee a variety of tools and state-of-the-art software that ensures your desired components are created with accuracy and precision.

Why should I choose CNC machining?

CNC machining has a ton of benefits to offer. This includes but is not limited to accuracy, precision, fast turnaround, versatility of solutions, ability to work with a number of materials, and being an overall economic solution in comparison to other solutions present in the market.

What determines the cost of CNC machined parts?

The cost of a CNC machined part is determined by the following four factors. 1) time required for machining, 2) type of material selected, 3) the geometry of the part to be machined, and 4) the startup cost of the project. Besides the stated requirements of the client, we try to make sure we take a course of action that leads to low cost without compromising the quality of the product produced. To determine cost for your project, you can request a free quote.

What materials can be utilized in your precision CNC machining processes?

Our CNC machining services are compatible with a wide range of materials, including various metals like aluminum, steel, and titanium, as well as plastics like ABS, polycarbonate, and PEEK. We select materials based on the specific requirements and applications of your project.

How do you guarantee the accuracy and quality in your CNC fabrication and milling operations?

We ensure quality and accuracy through rigorous quality control processes, including regular inspections and using precision measuring tools. Our skilled machinists and advanced CNC equipment are key to maintaining high standards in every project.

Is your facility equipped to handle large-scale CNC production orders?

Yes, our facility is equipped to handle both small and large-scale production orders. We have a range of CNC machines capable of meeting various production demands, ensuring timely delivery for bulk orders.

What are the standard lead times for completing CNC milling projects?

Lead times vary depending on the complexity and volume of the order. Typically, small projects can be completed within a week, while larger or more complex orders may take several weeks. We always strive to meet your deadlines and can provide expedited services when necessary.

How does your CNC machining service manage complex designs and intricate geometries?

Our advanced CNC machines, coupled with skilled programming and machining expertise, allow us to handle complex designs and intricate geometries. We work closely with clients to ensure their specifications are met, regardless of complexity.

What is the protocol for modifications or changes during a CNC machining order?

We accommodate modifications or changes whenever possible. If changes are needed after production has begun, we’ll discuss the implications on timing and cost and work with you to find the best solution.

Are there specific design guidelines for optimizing parts for your CNC machining and milling processes?

Yes, we recommend certain design practices to optimize for CNC machining, such as minimizing complex geometries, avoiding very thin walls, and considering the limitations of tool access. We’re happy to provide detailed guidelines to ensure efficient and effective machining of your parts.