Production Tooling services

- Molds For Production Runs

- Ensuring part Consistency With Scientific Methods

- Comprehensive Analysis of Molds

- Proprietary automated CMM process With Relevant Reports

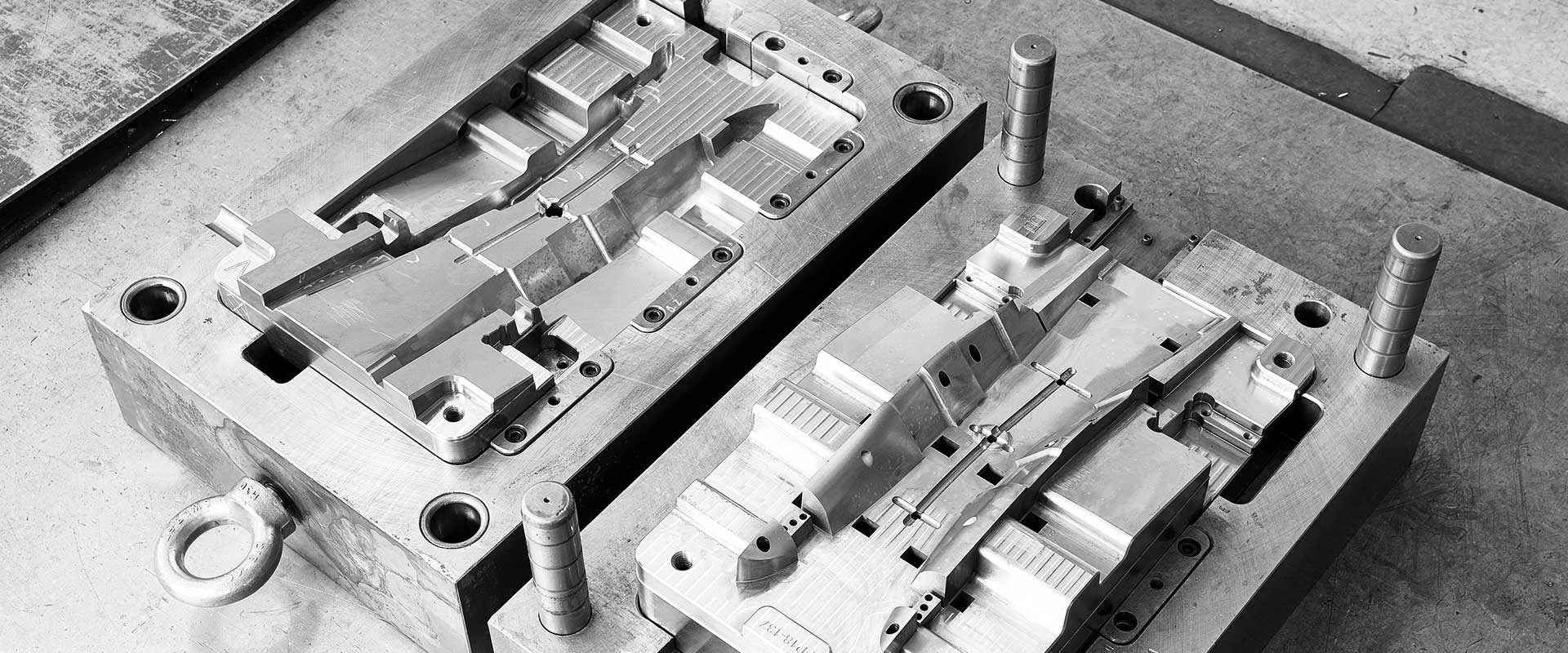

Prototool’s Production Mold Making is the ideal process for the on-demand manufacturing of high quality production molds in a short matter of time. Proficient in a variety of molding techniques, ranging from steel to a variety of allows and other sturdy metals, we help you develop molds that allow for mass production. It is a fundamental process for achieving reliable results. We understand the complex requirements behind making a reliable production mold and mind each and every constraint that separates and experienced manufacturer from an amateur manufacturer. Rest assured, the final product is sure to meet your requirements.

Place a free quote today and receive your Prototype Mold ASAP!

why Choose Us

Wide Range Of Molds

Ranging from CNC to other forms of production mold making, we offer a variety of tools and production processes that we believe meet every requirement our clients have to ask of us. We can develop molds that allow you to print over many millions of final products with no deterioration in the mold or piece produced.

Quick Turnaround

We understand that markets are highly competitive and reaching the market first can make all the difference. This is why our capable team of engineers and technicians are ever-ready to deliver your molds on tight deadlines while ensuring there is never any compromise on quality with a faster access to market.

DFM Reports

Do you need a Design For Manufacturability (DFM) report? We can help! Despite checking design feasibility before production we still offer a rapid DFM report to provide an expert opinion so you can reconsider the flaws in your design. The report includes identification of design flaws & errors that may cause problems down the line in the manufacturing.

High Quality Molds

Before you put your product in production, you want to make sure that the mold holds fast under testing conditions. For that, you need high quality molds that we are known to manufacture and deliver.

Why Choose Us

The machining industry is brimming with countless molding companies. But we have some solid reasons to hand over your molding projects (whether plastic injection molds or molds for die casting services) to us. Here’s why:

Wide Range Of Molds

Ranging from CNC to other forms of production mold making, we offer a variety of tools and production processes that we believe meet every requirement our clients have to ask of us. We can develop molds that allow you to print over many millions of final products with no deterioration in the mold or piece produced.

Quick Turnaround

We understand that markets are highly competitive and reaching the market first can make all the difference. This is why our capable team of engineers and technicians are ever-ready to deliver your molds on tight deadlines while ensuring there is never any compromise on quality with a faster access to market.

DFM Reports

Do you need a Design For Manufacturability (DFM) report? We can help! Despite checking design feasibility before production we still offer a rapid DFM report to provide an expert opinion so you can reconsider the flaws in your design. The report includes identification of design flaws & errors that may cause problems down the line in the manufacturing.

High Quality Molds

Before you put your product in production, you want to make sure that the mold holds fast under testing conditions. For that, you need high quality molds that we are known to manufacture and deliver.

Process For making Mold

Production mold making is a complex process the requires the expertise of highly experienced technicians and engineers. A standard procedure for production mold making will involve the following steps:

Manufacturability Analysis

The first step is the analysis of the manufacturability of the production mold. If it can be manufactured, we will start on it right away; otherwise, we will provide our DFM report to the client.

Design & Flow Analysis

Next, we employ the use of predictive modelling software that helps us to determine whether the mold will behave as it should or not. We make all the necessary changes and improvements to make sure it will.

Mold Making

The next step involves making the actual mold with the desired material of the customer. For this step, High Quality machines and equipment is used to produce a mold that will perform as intended with the material it will be used for.

Sampling

Samples are produced from the mold to make sure the end product fits the requirements of the client or if further amendment is needed.

Shipping

When our engineers are satisfied with the end product, the product is shipped to the customer. Afterwards, we stay in contact with the customer to ensure they are satisfied with the product they have received.

We Provide the Best Service in Industry

Die Casting Molds

Suitable for both, prototypes and mass production, die casting molds are made of hardened steel, making them highly sturdy and reliable. You can use a variety of materials and alloys in them for mass scale production.

Metal Injection Mold

It is a form of injection molding where feedstock consists of metal and binder. Made from high grade tool steel, it is designed to withstand metal injection. Other substitutes include aluminum. It is highly popular for production mold casting.

Vacuum Casting Mold

Vacuum Casting is a method used to make high-quality prototypes or parts in low volumes without any tooling cost. This method allows you to take advantage of speed, precision, size, cost, and even volume.

Available Production Molding Techniques

What Makes Us Stand Out?

Professional Team

Offering a wide range of production molds, we are one of the most prominent mold making companies that is trusted and relied upon by a wide range of customers who believe in our capabilities. Our strong and capable team of engineers have satisfied the needs of hundreds of industry professionals before and we can do the same for you.

Precision & Accuracy

We have provided industry professionals with production molds of high degree precision, accuracy, and limited tolerance. Moreover, we offer guarantee for our parts in terms of their strength & functionality.

Multi Materials

We specialize in production mold making that is suitable for a wide range of metals and alloys, as such, we will help you identify the type of mold suitable for your mass production needs. You can count on us to make your final products exactly as you wish.

Industries That Use Production Molds

There are a variety of industries that rely on production molds for the mass manufacturing of the final product. This inlcudes

Production Mold/Tooling Making FAQs

Key Insights on Production Tooling and Mold Manufacturing Services

What is the Typical Lifespan of a Production Mold?

The life of a production mold depends on the material and also on how many pieces are produced. But most often molds can be used for hundreds of thousands of cycles, particularly if they are made with hardened steel or durable aluminum.

How Do You Ensure Precision in Production Mold Fabrication?

The production molds are precision instruments which require CNC machining and strict quality-control measures to fabricate. All the molds we produce are dimensionally accurate because of our use of state-of-the art equipment.

What materials are best suited for high-volume production mold?

Those used for high-volume mold production are made from durable materials such as hardened steel or aluminum which can withstand the repeated cycle of manufacturing operations.

Are Production Toolings Suitable for Complicated Geometry

Absolutely. Our rigorously developed production tooling skills can accommodate special geometries, so that under any circumstances the molded article will not fail to meet design requirements.

How Much Time Does it Take to Manufacture Custom Production Molds?

Custom production mold manufacture turnaround time depends on the severity of detail in each specific case and current work load. We provide the fastest possible service without affecting quality instructions.

Is There Any Limit to Production Tooling Sizes?

In production toolings, size limitations are based on the capabilities of our equipment. We can accept a broad range in mold sizes and we’ll find you one that meets your needs as closely as possible.

How Do You Go About Quality Control of Production Tooling?

For production tooling, the quality assurance process includes in-depth inspection and testing of industry standards. Every mold must be able to produce high-quality parts repeatedly.

Are Production Molds suitable for plastics and metals?

Production molds are used for plastic parts, but many metals require different manufacturing processes (such as die casting or CNC machining).

How Does One Go About Designing a Custom Production Mold?

Making a new custom production mold requires careful study of the part, material composition and quantity to be produced. We employ CAD software in order to design molds specifications designed exactly according your requirements.

Do You Offer Quick Trial Production Before Completion of Tooling?

Sure, and we can do rapid prototyping to check out the part design so that you know if it will suit your needs before tooling up for production.

Is It Possible to Modify Production Molds After Initial Manufacture?

Production molds can be modified, but only to a certain degree. For some designs slight alterations may suffice; for others one might need to make an entirely new mold.

How Much Does Mold Manufacturing Cost?

The cost varies according to the size and complexity of molds, materials used, fineness required for specific applications etc.