Services d'outillage de production

- Moules pour les séries de production

- Assurer la cohérence des parties avec les méthodes scientifiques

- Analyse détaillée des moules

- Processus CMM automatisé exclusif avec rapports pertinents

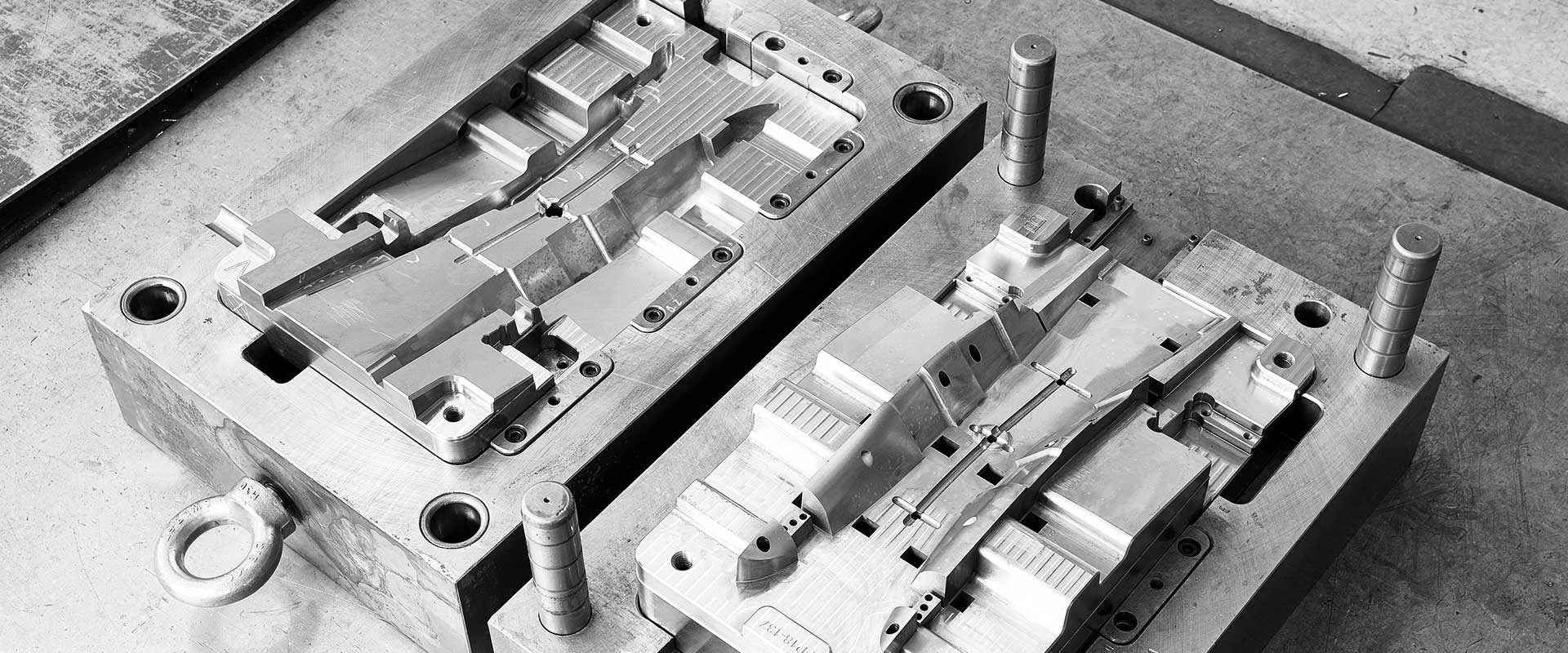

La fabrication de moules de production de Prototool est le processus idéal pour la fabrication à la demande de moules de production de haute qualité en peu de temps. Maîtrisant toute une série de techniques de moulage, allant de l'acier à une variété de métaux résistants, nous vous aidons à développer des moules permettant une production de masse. Il s'agit d'un processus fondamental pour obtenir des résultats fiables. Nous comprenons les exigences complexes liées à la fabrication d'un moule de production fiable et nous tenons compte de toutes les contraintes qui séparent un fabricant expérimenté d'un fabricant amateur. Soyez assuré que le produit final répondra à vos exigences.

Demandez un devis gratuit dès aujourd'hui et recevez votre moule prototype dans les plus brefs délais !

Pourquoi nous choisir ?

Large gamme de moules

De la CNC à d'autres formes de fabrication de moules de production, nous offrons une variété d'outils et de processus de production qui, selon nous, répondent à toutes les exigences de nos clients. Nous pouvons développer des moules qui vous permettent d'imprimer plusieurs millions de produits finaux sans détérioration du moule ou de la pièce produite.

Délai d'exécution rapide

Nous savons que les marchés sont très concurrentiels et que le fait d'arriver le premier sur le marché peut faire toute la différence. C'est pourquoi notre équipe d'ingénieurs et de techniciens compétents est toujours prête à livrer vos moules dans des délais serrés tout en veillant à ce qu'il n'y ait jamais de compromis sur la qualité avec un accès plus rapide au marché.

Rapports DFM

Avez-vous besoin d'un rapport sur la conception pour la fabrication (DFM) ? Nous pouvons vous aider ! Bien que la faisabilité de la conception soit vérifiée avant la production, nous proposons toujours un rapport DFM rapide pour fournir un avis d'expert afin que vous puissiez reconsidérer les défauts de votre conception. Le rapport comprend l'identification des défauts et des erreurs de conception qui peuvent causer des problèmes lors de la fabrication.

Moules de haute qualité

Avant de mettre votre produit en production, vous voulez vous assurer que le moule tient bon dans les conditions d'essai. Pour cela, vous avez besoin de moules de haute qualité que nous sommes réputés pour fabriquer et livrer.

Pourquoi nous choisir ?

Le secteur de l'usinage regorge d'innombrables entreprises de moulage. Mais nous avons quelques bonnes raisons de nous confier vos projets de moulage (qu'il s'agisse de moules d'injection plastique ou de moules pour les services de moulage sous pression). Voici pourquoi :

Large gamme de moules

De la CNC à d'autres formes de fabrication de moules de production, nous offrons une variété d'outils et de processus de production qui, selon nous, répondent à toutes les exigences de nos clients. Nous pouvons développer des moules qui vous permettent d'imprimer plusieurs millions de produits finaux sans détérioration du moule ou de la pièce produite.

Délai d'exécution rapide

Nous savons que les marchés sont très concurrentiels et que le fait d'arriver le premier sur le marché peut faire toute la différence. C'est pourquoi notre équipe d'ingénieurs et de techniciens compétents est toujours prête à livrer vos moules dans des délais serrés tout en veillant à ce qu'il n'y ait jamais de compromis sur la qualité avec un accès plus rapide au marché.

Rapports DFM

Avez-vous besoin d'un rapport sur la conception pour la fabrication (DFM) ? Nous pouvons vous aider ! Bien que la faisabilité de la conception soit vérifiée avant la production, nous proposons toujours un rapport DFM rapide pour fournir un avis d'expert afin que vous puissiez reconsidérer les défauts de votre conception. Le rapport comprend l'identification des défauts et des erreurs de conception qui peuvent causer des problèmes lors de la fabrication.

Moules de haute qualité

Avant de mettre votre produit en production, vous voulez vous assurer que le moule tient bon dans les conditions d'essai. Pour cela, vous avez besoin de moules de haute qualité que nous sommes réputés pour fabriquer et livrer.

Processus de fabrication des moules

La fabrication de moules de production est un processus complexe qui requiert l'expertise de techniciens et d'ingénieurs très expérimentés. Une procédure standard de fabrication de moules de production comprend les étapes suivantes :

Analyse de la fabricabilité

La première étape est l'analyse de la fabricabilité du moule de production. S'il est possible de le fabriquer, nous nous y attelons immédiatement ; dans le cas contraire, nous remettons notre rapport DFM au client.

Conception et analyse des flux

Ensuite, nous utilisons un logiciel de modélisation prédictive qui nous aide à déterminer si le moule se comportera comme il se doit ou non. Nous apportons toutes les modifications et améliorations nécessaires pour nous en assurer.

Fabrication de moules

L'étape suivante consiste à fabriquer le moule proprement dit avec le matériau souhaité par le client. Pour cette étape, des machines et des équipements de haute qualité sont utilisés pour produire un moule qui fonctionnera comme prévu avec le matériau pour lequel il sera utilisé.

Échantillonnage

Des échantillons sont produits à partir du moule pour s'assurer que le produit final répond aux exigences du client ou si d'autres modifications sont nécessaires.

Expédition

Lorsque nos ingénieurs sont satisfaits du produit final, celui-ci est expédié au client. Nous restons ensuite en contact avec le client pour nous assurer qu'il est satisfait du produit qu'il a reçu.

Nous fournissons le meilleur service de l'industrie

Moules de coulée sous pression

Convenant à la fois aux prototypes et à la production de masse, les moules de coulée sous pression sont fabriqués en acier trempé, ce qui les rend extrêmement robustes et fiables. Il est possible d'y utiliser une grande variété de matériaux et d'alliages pour la production en série.

Moule à injection de métal

Il s'agit d'une forme de moulage par injection dans laquelle la matière première est constituée de métal et de liant. Fabriqué en acier à outils de haute qualité, il est conçu pour résister à l'injection de métal. D'autres substituts incluent l'aluminium. Il est très populaire pour le moulage de production.

Moule de coulée sous vide

La coulée sous vide est une méthode utilisée pour fabriquer des prototypes ou des pièces de haute qualité en faibles volumes, sans coût d'outillage. Cette méthode permet de tirer parti de la vitesse, de la précision, de la taille, du coût et même du volume.

Techniques de moulage de production disponibles

Qu'est-ce qui nous distingue ?

Équipe professionnelle

Offrant une large gamme de moules de production, nous sommes l'une des entreprises de fabrication de moules les plus en vue, qui bénéficie de la confiance d'un grand nombre de clients qui croient en nos capacités. Notre équipe d'ingénieurs, forte et compétente, a déjà satisfait les besoins de centaines de professionnels de l'industrie et nous pouvons faire de même pour vous.

Precision & Accuracy

Nous avons fourni aux professionnels de l'industrie des moules de production d'une grande précision, d'une grande exactitude et d'une tolérance limitée. En outre, nous offrons une garantie pour nos pièces en termes de résistance et de fonctionnalité.

Matériaux multiples

Nous sommes spécialisés dans la fabrication de moules de production adaptés à une large gamme de métaux et d'alliages. Nous vous aiderons donc à identifier le type de moule adapté à vos besoins de production de masse. Vous pouvez compter sur nous pour fabriquer vos produits finis exactement comme vous le souhaitez.

Industries qui utilisent des moules de production

De nombreuses industries ont recours à des moules de production pour la fabrication en série du produit final. Il s'agit notamment

FAQ sur la fabrication de moules et d'outillages de production

Aperçu des services de fabrication d'outils de production et de moules

Quelle est la durée de vie typique d'un moule de production ?

La durée de vie d'un moule de production dépend du matériau et du nombre de pièces produites. Mais le plus souvent, les moules peuvent être utilisés pendant des centaines de milliers de cycles, en particulier s'ils sont fabriqués en acier trempé ou en aluminium durable.

Comment garantir la précision dans la fabrication des moules de production ?

Les moules de production sont des instruments de précision dont la fabrication nécessite un usinage CNC et des mesures strictes de contrôle de la qualité. Tous les moules que nous produisons sont dimensionnellement précis grâce à l'utilisation d'un équipement de pointe.

Quels sont les matériaux les mieux adaptés aux moules de production en grande quantité ?

Ceux qui sont utilisés pour la production de moules en grande quantité sont fabriqués à partir de matériaux durables tels que l'acier trempé ou l'aluminium, qui peuvent résister au cycle répété des opérations de fabrication.

Les outils de production sont-ils adaptés à une géométrie compliquée ?

Absolument. Nos compétences rigoureusement développées en matière d'outillage de production peuvent s'adapter à des géométries spéciales, de sorte que, quelles que soient les circonstances, l'article moulé ne manquera pas de répondre aux exigences de la conception.

Combien de temps faut-il pour fabriquer des moules de production sur mesure ?

Les délais de fabrication des moules sur mesure dépendent de la rigueur des détails dans chaque cas spécifique et de la charge de travail actuelle. Nous fournissons le service le plus rapide possible sans affecter la qualité des instructions.

Y a-t-il une limite à la taille des outils de production ?

Pour les outils de production, les limites de taille sont basées sur les capacités de notre équipement. Nous pouvons accepter une large gamme de tailles de moules et nous vous trouverons celui qui répond le mieux à vos besoins.

Comment procéder au contrôle de la qualité de l'outillage de production ?

Pour l'outillage de production, le processus d'assurance qualité comprend une inspection et des tests approfondis des normes industrielles. Chaque moule doit pouvoir produire des pièces de haute qualité de manière répétée.

Les moules de production sont-ils adaptés aux plastiques et aux métaux ?

Les moules de production sont utilisés pour les pièces en plastique, mais de nombreux métaux nécessitent des processus de fabrication différents (tels que le moulage sous pression ou l'usinage CNC).

Comment concevoir un moule de production personnalisé ?

La fabrication d'un nouveau moule de production sur mesure nécessite une étude minutieuse de la pièce, de la composition du matériau et de la quantité à produire. Nous utilisons des logiciels de CAO afin de concevoir des moules dont les spécifications répondent exactement à vos exigences.

Proposez-vous une production d'essai rapide avant l'achèvement de l'outillage ?

Bien sûr, et nous pouvons faire du prototypage rapide pour vérifier la conception de la pièce afin que vous sachiez si elle répondra à vos besoins avant de l'outiller pour la production.

Est-il possible de modifier les moules de production après la fabrication initiale ?

Les moules de production peuvent être modifiés, mais seulement dans une certaine mesure. Pour certains modèles, de légères modifications peuvent suffire ; pour d'autres, il peut être nécessaire de fabriquer un moule entièrement nouveau.

Combien coûte la fabrication d'un moule ?

Le coût varie en fonction de la taille et de la complexité des moules, des matériaux utilisés, de la finesse requise pour des applications spécifiques, etc.