Services de moulage familial

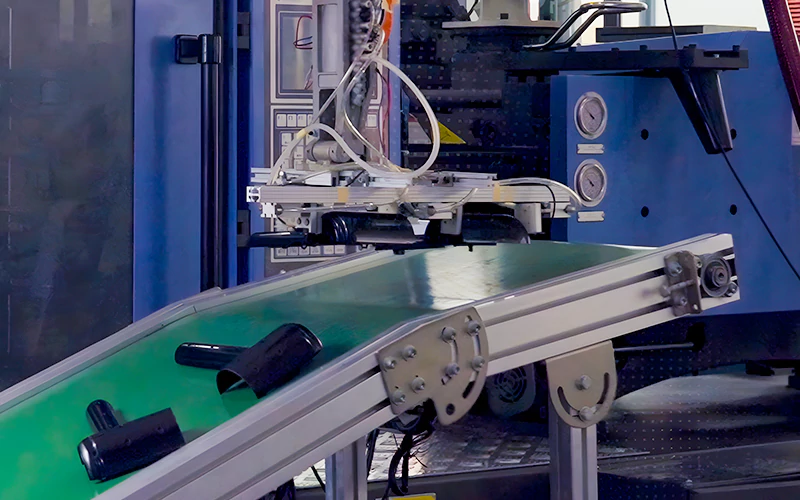

Family Molding Services fabrique des produits simultanément, efficacement et rapidement.

- Une solution économique

- Amélioration de la productivité manufacturière

- Haute qualité

Certifications : IATF16949:2016 | ISO9001:2015

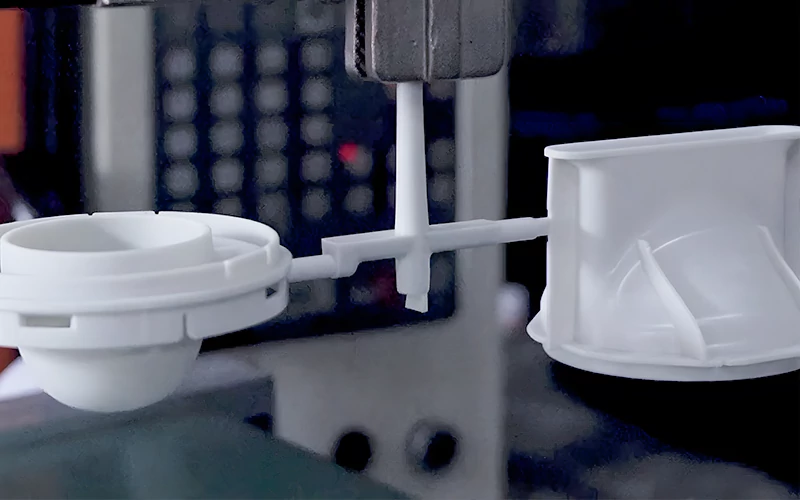

Un moule dans lequel plusieurs cavités ont été creusées pour fabriquer plusieurs pièces du même matériau en un seul cycle s'appelle un moule familial. En général, chacune de ces cavités forme un numéro de pièce différent, ce qui est idéal pour les moules prototypes en raison de la rapidité des cycles de moulage.

Le moule familial est un moule à plusieurs empreintes dans lequel chaque empreinte crée différentes parties d'un même produit. Les pièces produites par chaque empreinte peuvent également ne pas avoir de lien entre elles, mais appartenir à la même ligne de produits ou au même projet. Les moules familiaux sont parfaits pour la fabrication de pièces assemblées ou pour maximiser le nombre de pièces produites par opération.

Pourquoi nos services de moulage familial

Une qualité sans compromis pour chaque pièce moulée de la famille

Nous proposons des tarifs très compétitifs, sans jamais faire de compromis sur la qualité des produits et des services. Nos systèmes de qualité des processus de fabrication et de moulage des moules familiaux permettent de garantir que chaque pièce destinée à servir votre application unique ne sera pas en deçà de nos normes élevées à tout moment du cycle de production.

Large choix de matériaux et d'options personnalisées

Nous disposons de plus de 100 types de matériaux pour la fabrication de moules familiaux et le processus de moulage familial, y compris des options de spécifications personnalisées pour répondre à vos besoins. Cette flexibilité vous permet de choisir le matériau le mieux adapté à votre idée de produits moulés en famille, afin que votre produit final fonctionne parfaitement.

Un moulage familial économique et efficace

Grâce à la combinaison avancée de l'automatisation et des techniques de moulage par injection de précision, nous nous efforçons d'atteindre un rapport coût-efficacité parfait sans compromis sur la qualité. Notre stratégie vise à respecter vos budgets tout en surpassant les autres fournisseurs en matière de processus de fabrication de moules familiaux.

Production rapide et livraison dans les délais

Des équipements de production automatisés, un personnel qualifié et des flux de travail fluides Nous vous garantissons un prototypage de moules familiaux et une production de moules familiaux dans les délais. Votre projet est réalisé dans les délais lorsque nous le faisons !

Comment travailler avec nos services de moulage familial

Lancez votre projet de moulage familial

Tout d'abord, soumettez une demande de devis avec les informations sur votre produit et les dessins techniques éventuels. Si vous n'avez pas de dessins techniques, il n'y a pas de problème. Notre équipe peut faire de l'ingénierie inverse pour la conception de moules familiaux.

Analyse DFM et devis personnalisé

Vous pouvez espérer une réponse dans les 24 heures. Nous ferons votre demande de moulage familial et vous donnerons une conception DFM gratuite, en veillant à ce que le processus de création de moules pour la production de masse soit aussi efficace et précis que possible.

Outillage et production de moules familiaux

Après approbation du devis et versement d'un acompte, nous entamons le processus d'outillage de précision. Nous utilisons la conception de votre moule familial personnalisé pour régler nos machines en fonction du projet de chaque client. Notre objectif est toujours d'obtenir des moules multi-empreintes de haute qualité, adaptés exactement aux exigences des clients et dans les délais impartis.

Expédition fiable et commande facile

Ici, vos pièces de moulage familiales sont joliment emballées, étiquetées et expédiées à temps. Il est également très facile de commander ou de remplacer des moules.

Trouver des services de moulage familial de haute qualité ?

C'est ici que vous obtenez tout. Demandez votre devis gratuit dès aujourd'hui et profitez des meilleurs services de Family Mold.

Critères requis pour nos services de lutte contre les moisissures familiales

La procédure de moulage par injection familiale présente de nombreux avantages pour les fabricants et les clients. Cependant, elle s'accompagne également de certains défis et exigences qui doivent être respectés afin d'obtenir les meilleurs produits pour accomplir son application. Notre équipe d'experts accorde une attention particulière à toutes ces exigences, notamment :

Les pièces doivent être du même matériau et de la même couleur

Toutes les pièces produites par les moules familiaux doivent être du même matériau et de la même couleur, car un seul type de matériau peut être injecté dans le moule à un moment donné.

Les pièces seront toutes fabriquées dans la même quantité

Chaque fois que le moule s'ouvre, le nombre exact de pièces qu'il contient sort. Si le moule produit la face A et la face B pour fabriquer un produit complet, alors chaque fois que le moule s'ouvre, il produira suffisamment de pièces pour compléter un produit à chaque cycle.

Les pièces doivent avoir une taille et un volume similaires

Toutes les cavités du moule familial doivent être remplies en même temps et au même rythme. Le fait d'avoir des pièces de taille et de volume différents entraînera des problèmes de "short shot" et de "flash", c'est-à-dire des cavités insuffisamment remplies ou trop remplies, respectivement.

Matériaux utilisés pour le moulage de la famille

Voici les matériaux les plus couramment utilisés pour les moulures familiales :

ABS

ABS/PC

Acétal

Homopolymère d'acétal/Détrine

ETPU

PEHD

LCP

LDPE

PC/PBT

PEEK

PEI

PET

PETG

PMMA (acrylique, plexiglas)

Polycarbonate

Polypropylène

LLDPE

Nylon

PBT

PPA

EPI/PS

PS

PSU

TPU

Option de finition pour les pièces moulées en famille

Nous proposons plusieurs options de finition pour compléter les produits fabriqués selon le procédé du moule familial. Vous pouvez choisir l'une des options suivantes en fonction des exigences de votre application :

Finition standard

Finition intérieure non cosmétique selon la géométrie du moule.

Finitions SPI

Gamme de finitions SPI allant du grade 3 diamant / polissage élevé à la pierre 320 polissage faible. Ces options de finition comprennent SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2 et SPI D-3.

Inserts filetés

Nous pouvons installer les inserts standard les plus courants et les plus populaires dans les dimensions UNF et métriques.

Tel que moulé

comme son nom l'indique, le moule restera "tel quel" - sans texturation secondaire ni polissage.

Texture du moule

Création de textures sur les moules de manière à ce qu'elles apparaissent sur le produit final. Cette option de finition comprend le mat, les tourbillons, les motifs et les lignes.

Gravure au laser

Graver des numéros de pièces, des dessins, des logos ou toute autre impression spécifique sur vos pièces.

Tampographie

Application d'un dessin à base d'encre sur la surface.

Peinture

Peinture de la surface avec des couleurs standard ou assorties au Pantone, y compris l'apprêt et la couche de finition. Masquage disponible ; peinture EMI (cuivre).

Application industrielle et tolérance

Pour nos services de moulage familial, nous sommes généralement en mesure de maintenir une tolérance d'usinage de +/- 0,08 mm, avec une tolérance de résine incluse qui peut être supérieure, mais pas inférieure, à +/- 0,002 mm. /(0,002 mm/mm).

Le moulage par injection de moules familiaux est une procédure de fabrication populaire utilisée dans un large éventail d'industries pour fabriquer des ensembles de pièces différentes qui sont similaires ou qui peuvent s'adapter l'une à l'autre, comme les deux moitiés d'un même produit. Ce procédé est idéal pour :

FAQ sur le moulage familial

Obtenez des informations clés sur les services de moulage familial qui pourraient s'avérer cruciales pour vos besoins.

Qu'est-ce que le moulage familial ?

Les moules d'injection à cavité unique, les moules d'injection à cavités multiples et les moules familiaux sont-ils identiques ?

Y a-t-il des limites aux moules familiaux ?

Comment garantir la qualité du moulage familial ?

Pour garantir la compatibilité de toutes les pièces d'un moule familial en faisant correspondre les matériaux, les dimensions et les paramètres de moulage, nous appliquons un contrôle de qualité rigoureux. Chaque pièce est périodiquement inspectée et testée afin de déterminer si elle est conforme aux normes spécifiées.

Les moules familiaux peuvent-ils être utilisés pour des pièces complexes ?

Les moules familiaux fonctionnent mieux avec des pièces simples. Toutefois, ils ne conviennent pas pour les pièces simples, car la qualité d'un moule unique doit correspondre à celle d'autres moules lorsque le processus de production est cohérent.

Quels sont les types de produits les mieux adaptés au moulage familial ?

Comment déterminer si un moule familial convient à mon projet ?

Nous évaluons des facteurs tels que la conception des composants, la compatibilité des matériaux et l'étendue de la fabrication sur mesure. Si les éléments peuvent être correctement et efficacement produits collectivement sans compromettre la qualité, un moule familial peut être une option appropriée.

Comment garantissez-vous la qualité de vos pièces moulées par injection ?

Nous appliquons des mesures de contrôle strictes, comprenant des inspections normales et l'utilisation d'outils de dimensionnement avancés, afin de nous assurer que chaque composant répond aux spécifications requises.

Quel est le délai d'exécution type pour les projets de moulage familial ?

Les délais peuvent varier en fonction de la complexité du moule et de la quantité produite. Toutefois, les moules familiaux réduisent généralement les délais ordinaires en raison de leur efficacité dans la production simultanée de plusieurs pièces.

Les moules familiaux peuvent-ils réduire les coûts de production globaux ?

Oui, les moules familiaux peuvent réduire considérablement les prix de production. En moulant plusieurs composants simultanément, ils maintiennent les frais d'outillage, réduisent les temps de cycle et limitent la main-d'œuvre, ce qui se traduit principalement par des prix normaux.

Comment les exigences en matière de matériaux affectent-elles les moules familiaux ?

Toutes les pièces d'un moule familial doivent généralement être fabriquées à partir du même matériau, car le moule est conçu pour une résine plastique spécifique. Cette uniformité garantit une température de fusion et un comportement du matériau cohérents au cours du processus de moulage.

Les moules familiaux sont-ils adaptés à la production en grande série ?

Les moules familiaux sont particulièrement utiles pour les productions en grande série. Ils permettent la production simultanée de plusieurs pièces, augmentant ainsi la production et l'efficacité, en particulier pour les commandes importantes de petites et moyennes pièces.