Service d'usinage CNC

Services d'usinage CNC sur mesure, capacités 4 et 5 axes, spécialisés dans les prototypes CNC rapides et la production à la demande.

- Délai d'exécution rapide (1 jour)

- Tolérance serrée jusqu'à 0,01 mm

Certifications : IATF16949:2016 | ISO9001:2015

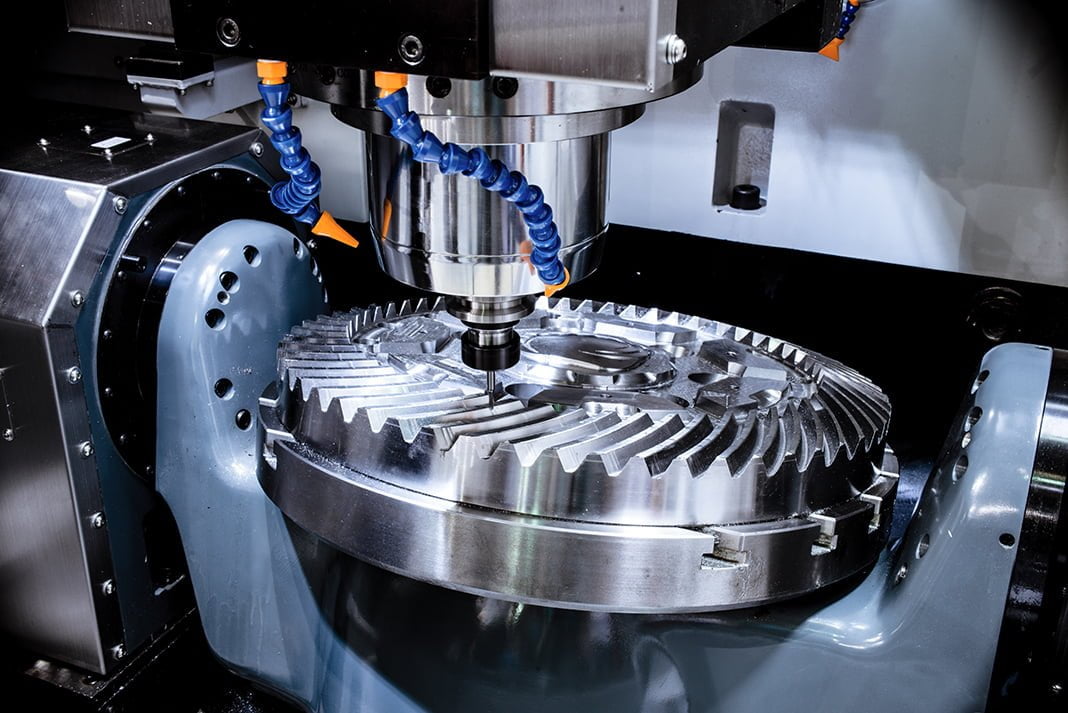

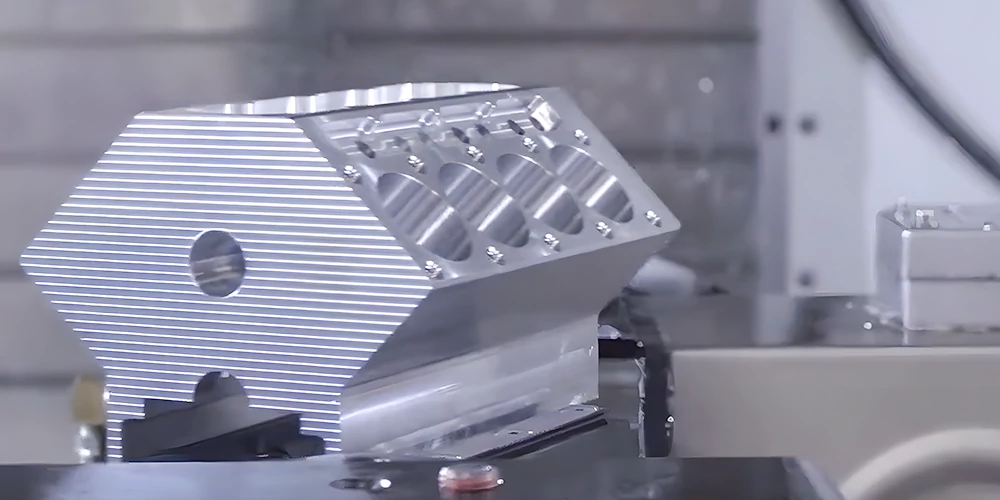

Prototool propose des services de fabrication CNC de précision. Nous disposons de nombreux types d'équipements d'usinage de haute précision : centres d'usinage CNC à 5 axes, centres d'usinage CNC à 4 axes, centres de haute précision, etc. Notre atelier d'usinage a plus de dix ans d'expérience dans les blocs moteurs, les pièces automobiles, les culasses, les arbres rotatifs, les arbres de transmission, les engrenages, les boîtes de vitesse, les tambours de frein, les moyeux, les culbuteurs, les arbres de culbuteur, les pièces de moteur à réaction, les composants d'appareils médicaux, etc. Nous sommes fiers de la recherche constante de rapidité, de précision, de polyvalence et de service de la part de tous nos employés.

Pourquoi nous choisir ?

Équipements de marques multiples

Notre atelier est équipé d'un ensemble de machines CNC de marque très performantes, notamment de marques réputées telles que Haas, GF+, Mazak, etc. Notre gamme complète d'équipements CNC comprend une variété de types, tels que des centres d'usinage à 5 et 4 axes, ainsi que des outils d'usinage de précision avancés.

Délais d'exécution rapides

L'équipe d'experts en usinage de précision de Prototool et son flux de travail rationalisé, qui s'appuient sur plus de dix ans d'expérience dans divers projets, garantissent une exécution rapide et précise de vos commandes. Notre configuration est optimisée pour des services d'usinage personnalisés rapides et de haute qualité, garantissant une livraison dans les délais pour chaque projet.

Haute précision et qualité

Grâce à ses outils de fabrication CNC avancés et aux connaissances approfondies de son équipe en matière d'ingénierie de précision, Prototool garantit une précision exceptionnelle pour chaque projet, en maintenant des tolérances aussi étroites que +0,01 à +0,02 mm. Cet engagement en faveur de la précision garantit la plus haute qualité de tous nos services d'usinage CNC.

Fabrication rentable

Prototool ne se contente pas de proposer des prix compétitifs dans le domaine de l'usinage CNC. Nous travaillons en étroite collaboration avec nos clients et leur offrons des conseils d'experts en matière de conception et de matériaux afin d'optimiser les performances de leurs produits. Cette approche garantit des solutions d'usinage personnalisées rentables et de haute qualité, qui vous permettent de rentabiliser votre investissement.

Precision Without Borders

At Prototool, our dual-base CNC machining hubs in China and Mexico deliver unmatched agility for high-tolerance metal and plastic parts. Whether you need prototypes tomorrow or scaled production next month, we turn complexity into certainty—globally compliant, locally competitive.

Speed Redefined:

- Rapid Turnaround: 3-5 days for prototypes (aluminum/plastics), 10-12 days for hardened steel production parts.

- 24/7 Capacity: Mexico facility operates 3 shifts to meet urgent OEM demands.

Tariff-Optimized Sourcing:

- China: Cost-efficient, large-volume production for Asian and European markets.

- Mexico: Duty-free access to North America via USMCA, slashing your landed costs by up to 25%.

Precision Guaranteed:

- ±0.005mm tolerances with 5-axis CNC, CMM inspection, and ISO 9001-certified workflows.

- Materials mastery: aerospace alloys (Ti6Al4V, Inconel), medical-grade stainless steel, engineering plastics (PEEK, Ultem).

Étapes pour s'engager avec nos experts en usinage CNC

Soumettre une demande

Commencez par soumettre votre demande de devis gratuit, accompagnée de la description des produits et des dessins techniques. Si vous n'avez pas de dessin technique, notre équipe d'usinage de précision peut vous aider à réaliser une rétroconception.

DFM & Quotation

Nos experts en usinage sur mesure examineront votre demande et vous fourniront un devis détaillé, généralement dans les 24 heures, garantissant ainsi une réponse rapide à vos besoins en matière d'usinage CNC.

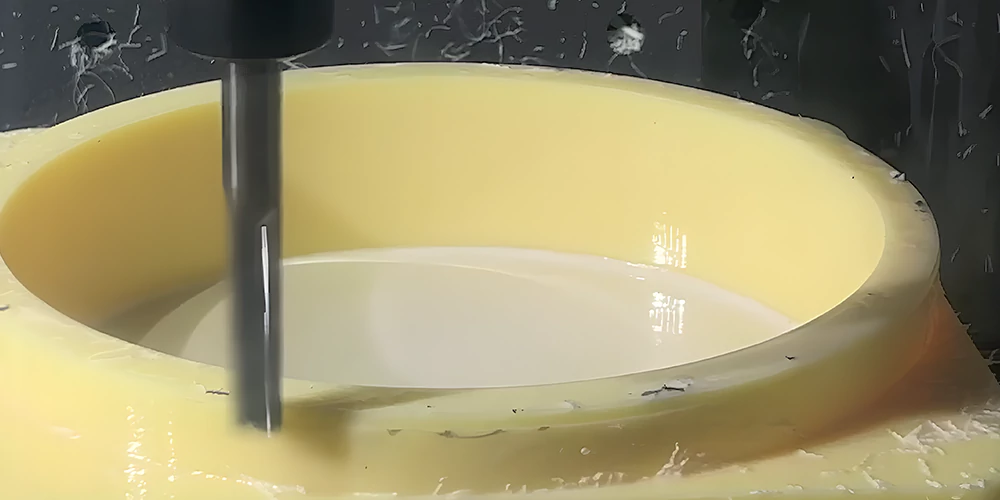

Processus d'usinage

Une fois le devis approuvé et l'acompte reçu, nous lançons le projet. Cela implique la préparation de nos machines CNC avancées et le début du processus de fabrication de précision, adapté à vos spécifications.

Expédition

Vos produits usinés CNC sont soigneusement emballés, étiquetés et expédiés directement à votre domicile, ce qui garantit une livraison rapide et sûre.

Qualité supérieure, délais d'exécution rapides

Options de service d'usinage CNC

Service de fraisage CNC

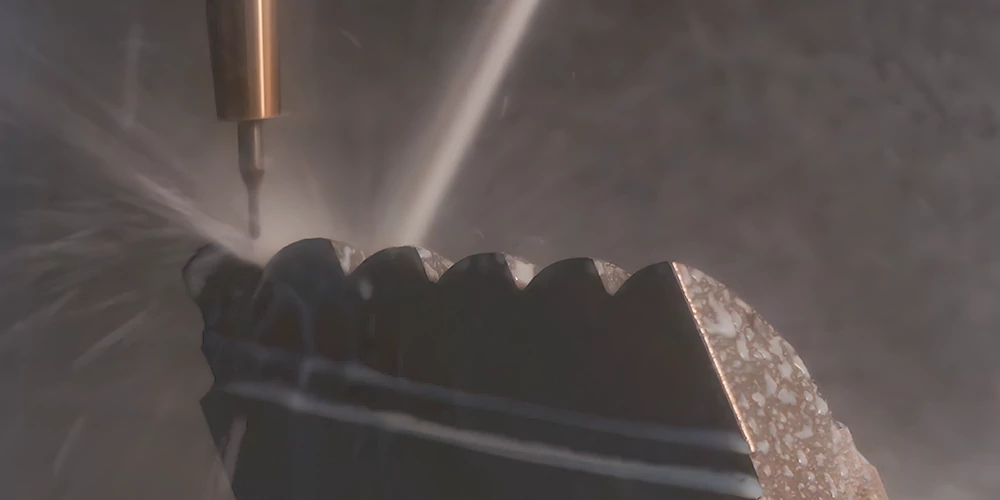

Spécialisé dans les géométries complexes et les pièces de précision, notre processus de fraisage CNC est idéal pour les composants tels que les pièces de moteur, les cadres et les boîtiers. Grâce à des fraiseuses de pointe, nous produisons des pièces d'une précision et d'une finition de surface exceptionnelles.

Service de tournage CNC

Parfait pour les pièces cylindriques telles que les arbres, les tiges et les douilles, notre tournage CNC garantit une grande précision et une excellente intégrité de la surface. Nos centres de tournage sont capables de traiter divers matériaux et de produire des pièces aux tolérances serrées et aux finitions lisses.

Matériaux usinés de manière experte par nos services CNC

Dans le cadre de nos services de fabrication CNC, nous traitons une gamme variée de matériaux, afin de répondre aux besoins spécifiques de nos clients. En outre, nous offrons la possibilité de trouver sur le marché le matériau idéal pour répondre aux exigences de l'application.

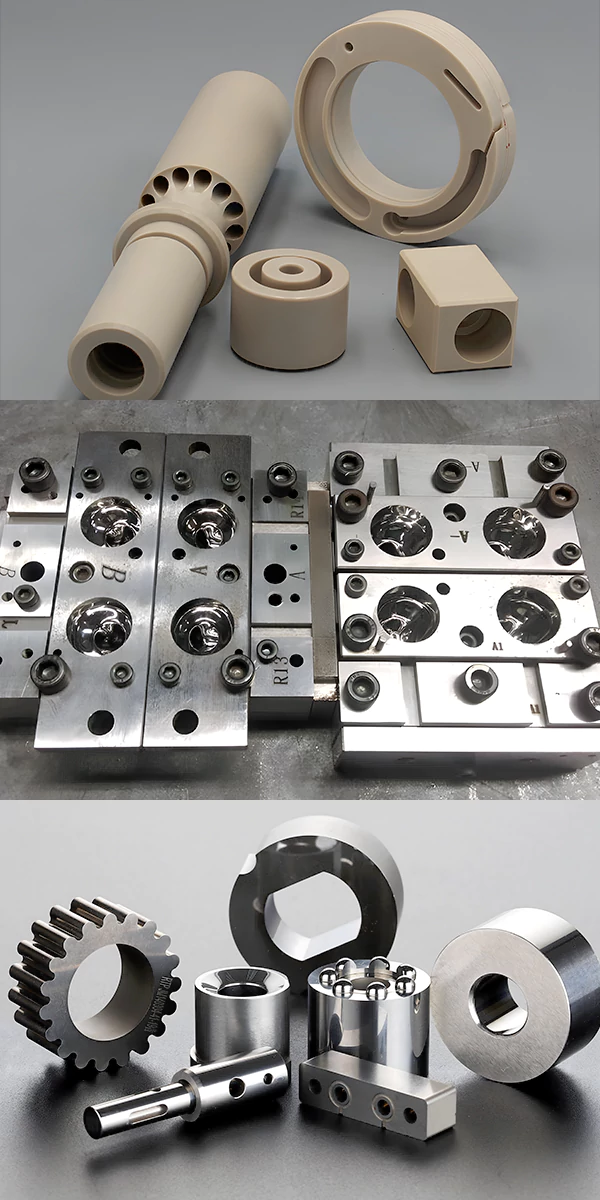

Plastique : Grâce à nos capacités d'usinage CNC de précision, le plastique est un choix populaire pour le développement de prototypes. Ce processus permet une évaluation complète de votre produit, ce qui vous permet d'évaluer minutieusement sa conception et sa fonctionnalité.

Métal : La polyvalence de nos services d'usinage CNC est particulièrement évidente lorsqu'il s'agit de travailler avec des métaux. Nous pouvons usiner une grande variété de métaux, ce qui est idéal pour le développement de prototypes et la création de pièces finales pour la fabrication.

Autres matériaux : Au-delà des plastiques et des métaux, nos solutions d'usinage CNC sur mesure s'étendent à un large éventail d'alliages et d'autres matériaux spécialisés, selon les demandes de nos clients.

Plastiques courants avec lesquels nous travaillons

ABS, ABS+PC, PC, PP, PEEK, POM, Acrylique (PMMA), Téflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE.

Métaux courants avec lesquels nous travaillons

Aluminium, laiton, cuivre, magnésium, titane, acier inoxydable, étain, zinc

Si le matériau souhaité ne figure pas dans la liste ci-dessus, contactez-nous et demandez un devis gratuit dès aujourd'hui !

Normes de tolérance de Prototool pour l'usinage CNC

Notre service de fraisage CNC offre une grande précision avec des tolérances de l'ordre de 0,01 à 0,05 mm. Veuillez noter que la tolérance dépend du type de matériau utilisé et de la géométrie de la pièce à fraiser. Pour plus de détails, consultez le tableau ci-dessous :

| Levier de tolérance | Gamme de dimensions globales | ||||||

| Spécifications | <0.5 | <3 | <6 | <30 | <120 | <400 | <1000 |

| Tolérance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Finitions de surface des pièces usinées CNC

Tel qu'usiné (Ra 3.2μm / Ra 126μin)

Usinage lisse (Ra 1.6μm / Ra 63μin)

Usinage fin (Ra 0.8μm / Ra 32μin)

Polissage (Ra 0.8μm / Ra 32μin)

Billes de verre

Brossé + Anodisé type II (Brillant)

Tel qu'usiné + Anodisé type II

Revêtement de conversion au chromate

Oxyde noir

Placage de nickel chimique

Microbillage + Anodisation type II (Mat)

Microbillage + Anodisation type II (Brillant)

Brossé + électropoli (Ra 0.8μm / Ra 32μin)

Tel qu'usiné + Anodisé type III (Hardcoat)

Brossé (Ra 1.2μm / Ra 47μin)

Revêtement en poudre

Nos applications d'usinage CNC

Pour la fabrication de moules et de matrices

L'usinage CNC joue un rôle essentiel dans le développement de divers moules, notamment les moules d'injection plastique, les moules de moulage sous pression, les moules à deux tirs, les moules à deux plaques et les moules à trois plaques. Grâce à leur précision exceptionnelle, nos machines CNC peuvent sculpter rapidement des moules dans le métal souhaité, ce qui les rend très utiles pour l'outillage rapide ou l'outillage de production. Cette capacité nous permet de répondre efficacement à des besoins d'outillage divers et complexes, ce qui correspond parfaitement aux exigences de la fabrication rapide.

Dans le cadre de nos services d'usinage CNC, nous pouvons fabriquer des prototypes personnalisés pour une variété de secteurs, tels que des pièces automobiles détaillées comme des composants de moteur, des dispositifs médicaux complexes comme des prothèses, et des produits électroniques grand public comme des boîtiers de smartphones. Notre usinage de précision garantit que ces prototypes sont des représentations exactes des produits finaux, ce qui est idéal pour les essais et la validation. L'usinage CNC est rentable et efficace, permettant un prototypage rapide et précis à tous les stades.

Nous sommes spécialisés dans la fabrication de divers composants aérospatiaux, notamment des aubes de turbine, des supports de moteur, des pièces de train d'atterrissage et des éléments structurels d'aéronefs. Nos capacités d'usinage avancées s'étendent également à la production de raccords complexes, de composants de systèmes de commande et de sections de voilure. Chaque pièce est méticuleusement fabriquée pour répondre aux normes rigoureuses du secteur aérospatial, afin de garantir des performances et une sécurité optimales.

Nous sommes spécialisés dans la création de composants tels que les blocs moteurs, les engrenages de transmission, les systèmes de suspension et les mécanismes de direction. Notre usinage de précision permet également la production de systèmes d'échappement personnalisés, de composants de freinage et d'assemblages de soupapes complexes. Chaque pièce automobile est conçue pour résister aux rigueurs de l'utilisation quotidienne, ce qui garantit la fiabilité et les performances de chaque véhicule.

Nous fabriquons avec expertise des composants tels que des implants orthopédiques, des instruments chirurgicaux et des boîtiers d'équipement de diagnostic. Nos capacités s'étendent également à l'usinage de pièces complexes pour les appareils d'imagerie médicale, les outils dentaires et les prothèses sur mesure. Chaque pièce est fabriquée avec la plus grande précision et le plus grand soin, dans le respect de normes médicales strictes afin de garantir la sécurité et l'efficacité des applications de soins de santé.

Nous produisons habilement des composants pour les appareils ménagers, les équipements sportifs tels que les pièces de bicyclette et les pièces d'instruments de musique. En outre, notre expertise en matière d'usinage s'étend à la création de pièces détaillées pour des gadgets personnels, des articles de luxe, des articles de sport, des jouets, des ustensiles de cuisine et même des accessoires de meubles sur mesure. Chaque produit bénéficie de la précision et de l'assurance qualité qu'apporte l'usinage CNC.

Comprendre l'usinage CNC

Si vous êtes novice en matière de services d'usinage CNC, voici une brève introduction pour vous aider à démarrer :

Qu'est-ce que l'usinage CNC ?

L'usinage CNC, abréviation de Computer Numerical Control Machining, est un moyen de fabriquer des pièces en utilisant des ordinateurs pour contrôler les machines-outils. Elle est connue pour :

- Précision : Il fabrique des pièces avec une grande précision.

- Efficacité : Il est rapide et permet de réaliser facilement des formes complexes.

- Polyvalence : Utilisé pour tout, des voitures aux chaises en passant par les bateaux.

Comment fonctionne l'usinage CNC :

- Préparez le terrain : Nous examinons le projet et déterminons la meilleure façon de le réaliser.

- Régler la machine : Nous programmons la machine avec les bonnes instructions.

- Usinage : La machine coupe et façonne le matériau avec précision.

- Vérifier la qualité : Nous veillons à ce que chaque pièce soit parfaite.

Plus d'informations sur "Qu'est-ce que l'usinage CNC ?“

Pourquoi choisir l'usinage CNC

L'usinage CNC se distingue pour plusieurs raisons essentielles :

Précision inégalée : Il est incroyablement précis, ce qui en fait un choix de premier ordre pour les industries critiques telles que l'aérospatiale et les appareils médicaux.

Vitesse et polyvalence : Qu'il s'agisse d'un prototype, d'un produit final ou d'un moule, l'usinage CNC est rapide et permet de traiter facilement des conceptions complexes.

Sécurité et fiabilité : Le processus minimise l'erreur humaine, ce qui garantit une qualité et une sécurité constantes.

Large compatibilité avec les matériaux : L'usinage CNC est adaptable, il travaille avec une gamme de matériaux pour répondre aux différents besoins de l'industrie.

Efficacité pour les fabricants : Il nécessite peu d'entretien et peut fonctionner en continu, ce qui en fait une solution rentable.

Idéal pour les tâches complexes : Du fraisage au tournage, l'usinage CNC est parfait pour les conceptions complexes et les tâches d'usinage non conventionnelles.

FAQ sur l'usinage CNC

Vous trouverez peut-être ici des informations utiles sur les services d'usinage CNC.

Quelles sont les applications de l'usinage CNC ?

L'usinage CNC est un processus utilisé pour concevoir des pièces de machines qui peuvent être soit des porotypes, soit des pièces prêtes à être produites en série. C'est l'un des procédés les plus populaires pour la fabrication sur mesure. Il permet de traiter des géométries irrégulières de pièces complexes et peut même être utilisé pour la production en série de pièces une fois qu'un prototype a été approuvé.

Quels types de formats de fichiers prenez-vous en charge pour l'usinage CNC ?

Nous prenons en charge un certain nombre de formats de fichiers pour nous assurer que nous répondons toujours aux exigences de nos clients. Il s'agit notamment des formats populaires .stp, .sldprt et .psm/.par. En outre, nous veillons à travailler avec nos clients jusqu'à la fin pour qu'ils obtiennent le résultat souhaité, conçu à la perfection. C'est la valeur que nous défendons.

De quel type d'équipement disposez-vous ?

Chez Prototool, nous proposons non seulement des services de fraisage CNC à 3 et 4 axes, mais aussi des services de fraisage CNC à 5 axes (HAAS). Tous ces services fournissent d'excellents résultats, sauf lorsque vous avez besoin de résultats de qualité plus fine, nous suggérons le service de fraisage CNC 5 axes au lieu des services de fraisage 3 axes ou 4 axes. De plus, notre service de tournage CNC utilise une variété d'outils et de logiciels de pointe qui garantissent que vos composants souhaités sont créés avec exactitude et précision.

Pourquoi choisir l'usinage CNC ?

L'usinage CNC présente une multitude d'avantages. Il s'agit notamment de l'exactitude, de la précision, de la rapidité d'exécution, de la polyvalence des solutions, de la capacité à travailler avec un certain nombre de matériaux et d'une solution globalement économique par rapport à d'autres solutions présentes sur le marché.

Qu'est-ce qui détermine le coût des pièces usinées en CNC ?

Le coût d'une pièce usinée par CNC est déterminé par les quatre facteurs suivants. 1) le temps nécessaire à l'usinage, 2) le type de matériau choisi, 3) la géométrie de la pièce à usiner et 4) le coût de démarrage du projet. Outre les exigences formulées par le client, nous nous efforçons d'adopter une ligne de conduite qui permette de réduire les coûts sans compromettre la qualité du produit fabriqué. Pour déterminer le coût de votre projet, vous pouvez demander un devis gratuit.

Quels matériaux peuvent être utilisés dans vos processus d'usinage CNC de précision ?

Nos services d'usinage CNC sont compatibles avec une large gamme de matériaux, y compris divers métaux comme l'aluminium, l'acier et le titane, ainsi que des plastiques comme l'ABS, le polycarbonate et le PEEK. Nous sélectionnons les matériaux en fonction des exigences et des applications spécifiques de votre projet.

Comment garantir la précision et la qualité de vos opérations de fabrication et de fraisage CNC ?

Nous garantissons la qualité et la précision grâce à des processus rigoureux de contrôle de la qualité, notamment des inspections régulières et l'utilisation d'outils de mesure de précision. Nos machinistes qualifiés et nos équipements CNC avancés sont essentiels pour maintenir des normes élevées dans chaque projet.

Vos installations sont-elles équipées pour traiter des commandes de production CNC à grande échelle ?

Oui, nos installations sont équipées pour traiter les commandes de production à petite et à grande échelle. Nous disposons d'une gamme de machines à commande numérique capables de répondre à diverses demandes de production et de garantir une livraison dans les délais pour les commandes en grande quantité.

Quels sont les délais standard de réalisation des projets de fraisage CNC ?

Les délais d'exécution varient en fonction de la complexité et du volume de la commande. En règle générale, les petits projets peuvent être réalisés en une semaine, tandis que les commandes plus importantes ou plus complexes peuvent prendre plusieurs semaines. Nous nous efforçons toujours de respecter vos délais et pouvons fournir des services accélérés si nécessaire.

Comment votre service d'usinage CNC gère-t-il les conceptions complexes et les géométries compliquées ?

Nos machines CNC de pointe, associées à des compétences en matière de programmation et d'usinage, nous permettent de traiter des conceptions complexes et des géométries compliquées. Nous travaillons en étroite collaboration avec nos clients pour nous assurer que leurs spécifications sont respectées, quelle que soit leur complexité.

Quel est le protocole à suivre en cas de modifications ou de changements lors d'une commande d'usinage CNC ?

Nous acceptons les modifications ou les changements dans la mesure du possible. Si des changements sont nécessaires après le début de la production, nous discuterons des implications en termes de délais et de coûts et travaillerons avec vous pour trouver la meilleure solution.

Existe-t-il des directives de conception spécifiques pour optimiser les pièces pour vos processus d'usinage et de fraisage CNC ?

Oui, nous recommandons certaines pratiques de conception afin d'optimiser l'usinage CNC, notamment en minimisant les géométries complexes, en évitant les parois très fines et en tenant compte des limites d'accès à l'outil. Nous serons heureux de vous fournir des lignes directrices détaillées pour garantir un usinage efficace de vos pièces.