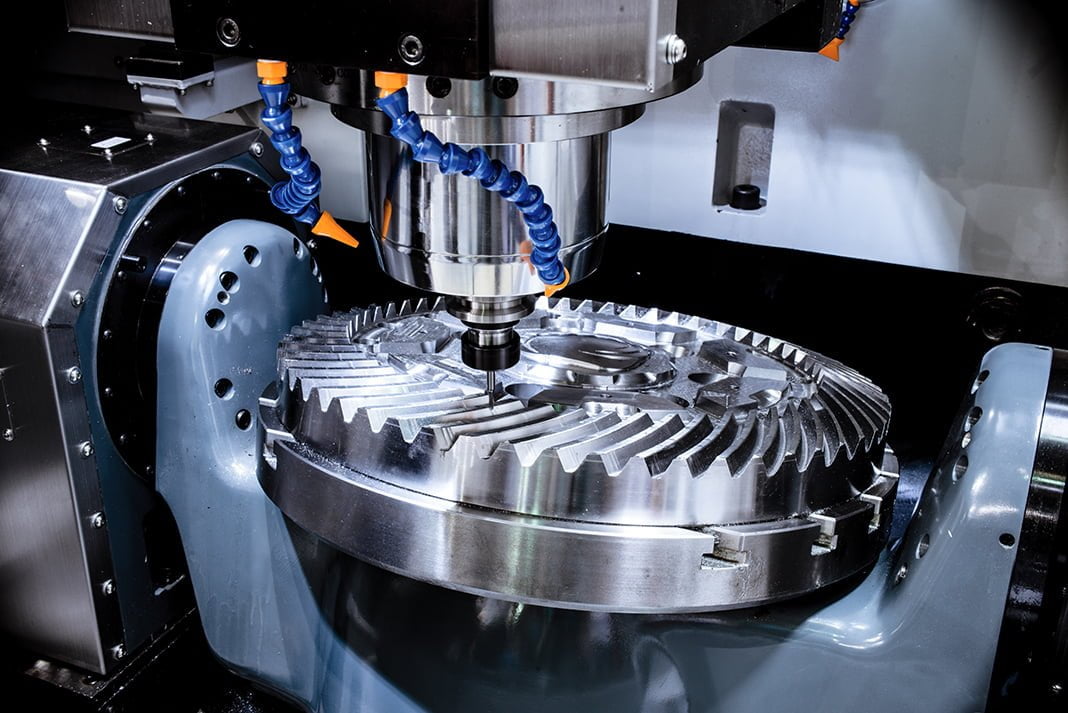

Servicio de mecanizado CNC

Servicios de mecanizado CNC personalizados, capacidades de 4 y 5 ejes, especializados en prototipos CNC rápidos y producción bajo demanda.

- Entrega rápida en 1 día

- Tolerancia ajustada de hasta 0,01 mm

Certificaciones: IATF16949:2016 | ISO9001:2015

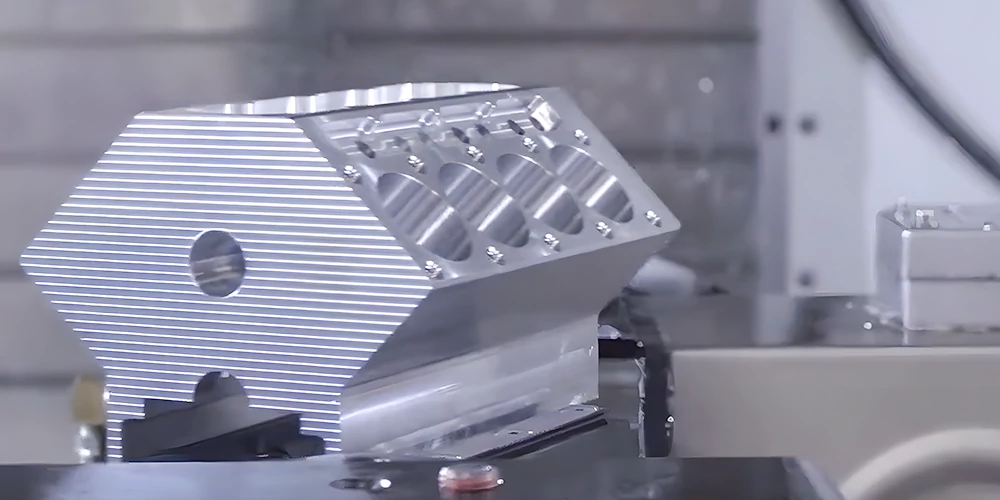

Prototool ofrece servicios de fabricación CNC de precisión. Disponemos de muchos tipos de equipos de mecanizado de alta precisión: Centros de mecanizado CNC de 5 ejes, centros de mecanizado CNC de 4 ejes, centros de alta precisión, etc. Nuestro taller de mecanizado tiene más de diez años de experiencia en bloques de motor, piezas de automoción, culatas, ejes rotativos, ejes de transmisión, engranajes, cajas de cambios, tambores de freno, bujes, balancines de engranajes, ejes de balancines, piezas de motores a reacción, componentes de dispositivos médicos, etc. Estamos orgullosos de la búsqueda constante de velocidad, precisión, versatilidad y servicio por parte de todos nuestros empleados.

Por qué elegirnos

Equipos de varias marcas

Nuestro taller está equipado con una amplia gama de maquinaria CNC de alto rendimiento y de marca, incluidas marcas notables como Haas, GF+, Mazak, etc. Nuestro completo conjunto de equipos CNC abarca una gran variedad de tipos, como centros de mecanizado de 5 y 4 ejes, junto con avanzadas herramientas de mecanizado de precisión.

Plazos de entrega rápidos

El equipo de expertos en mecanizado de precisión de Prototool y su flujo de trabajo optimizado, respaldado por más de diez años de experiencia en diversos proyectos, garantizan la finalización rápida y precisa de sus pedidos. Nuestra configuración está optimizada para ofrecer servicios de mecanizado personalizados rápidos y de alta calidad, garantizando la entrega puntual de cada proyecto.

Alta precisión y calidad

Gracias a nuestras avanzadas herramientas de fabricación CNC y a los profundos conocimientos de ingeniería de precisión de nuestro equipo, Prototool ofrece sistemáticamente una precisión excepcional en cada proyecto, manteniendo tolerancias tan ajustadas como +0,01 a +0,02 mm. Este compromiso con la precisión garantiza la máxima calidad en todos nuestros servicios de mecanizado CNC.

Fabricación rentable

Prototool va más allá de los precios competitivos en el mecanizado CNC. Trabajamos en estrecha colaboración con nuestros clientes, ofreciéndoles asesoramiento experto en diseño y materiales para optimizar el rendimiento del producto. Este enfoque garantiza soluciones de mecanizado personalizadas rentables y de alta calidad, que proporcionan un gran valor a su inversión.

Precision Without Borders

At Prototool, our dual-base CNC machining hubs in China and Mexico deliver unmatched agility for high-tolerance metal and plastic parts. Whether you need prototypes tomorrow or scaled production next month, we turn complexity into certainty—globally compliant, locally competitive.

Speed Redefined:

- Rapid Turnaround: 3-5 days for prototypes (aluminum/plastics), 10-12 days for hardened steel production parts.

- 24/7 Capacity: Mexico facility operates 3 shifts to meet urgent OEM demands.

Tariff-Optimized Sourcing:

- China: Cost-efficient, large-volume production for Asian and European markets.

- Mexico: Duty-free access to North America via USMCA, slashing your landed costs by up to 25%.

Precision Guaranteed:

- ±0.005mm tolerances with 5-axis CNC, CMM inspection, and ISO 9001-certified workflows.

- Materials mastery: aerospace alloys (Ti6Al4V, Inconel), medical-grade stainless steel, engineering plastics (PEEK, Ultem).

Pasos para contratar a nuestros expertos en mecanizado CNC

Enviar solicitud

Empiece por enviar su solicitud de presupuesto gratuito, con la descripción del producto y los planos técnicos. Si no dispone de un dibujo técnico, nuestro equipo de mecanizado de precisión puede ayudarle con ingeniería inversa.

DFM & Quotation

Nuestros expertos en mecanizado a medida revisarán su solicitud y le proporcionarán un presupuesto detallado, normalmente en 24 horas, garantizando una respuesta rápida a sus necesidades de mecanizado CNC.

Proceso de mecanizado

Una vez aprobado el presupuesto y recibido el depósito, iniciamos el proyecto. Esto implica preparar nuestra avanzada maquinaria CNC y comenzar el proceso de fabricación de precisión, adaptado a sus especificaciones.

Envío

Sus productos mecanizados por CNC se embalan y etiquetan cuidadosamente y se envían directamente a su puerta, garantizando una entrega puntual y segura.

Máxima calidad, entrega rápida

Opciones de servicio de mecanizado CNC

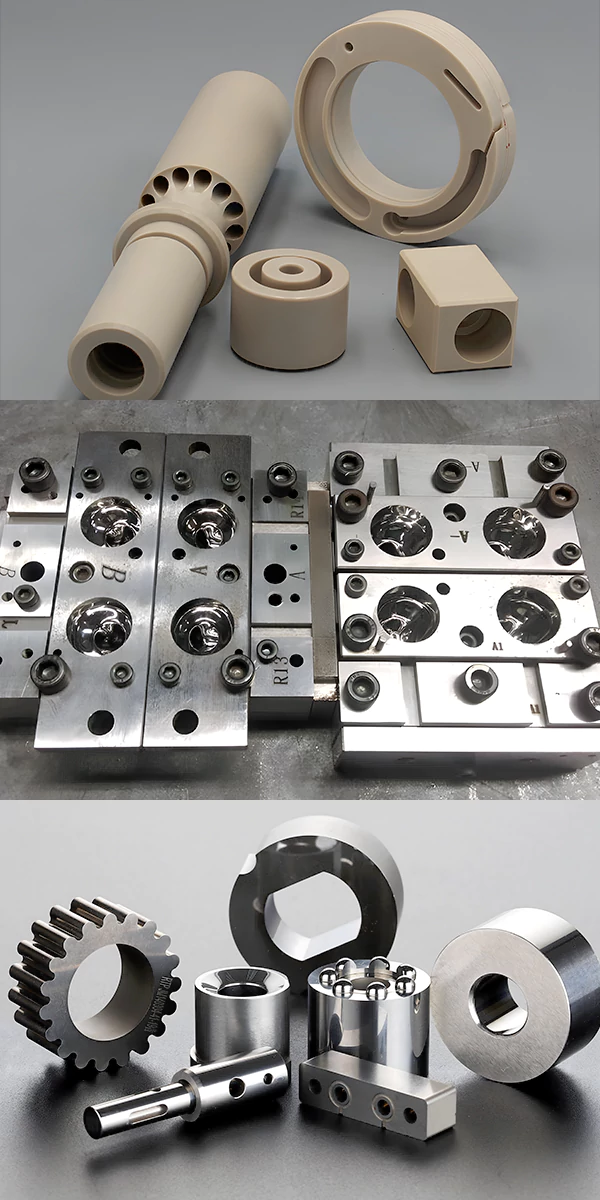

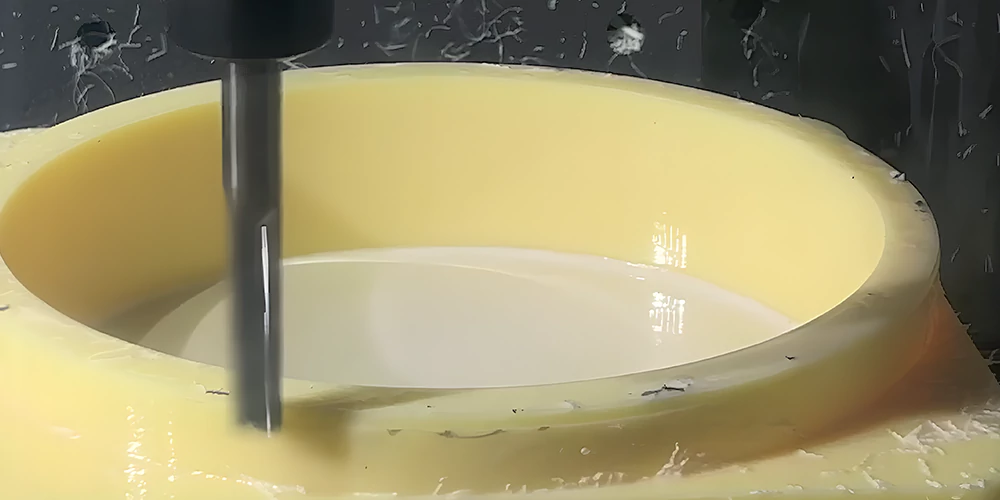

Servicio de fresado CNC

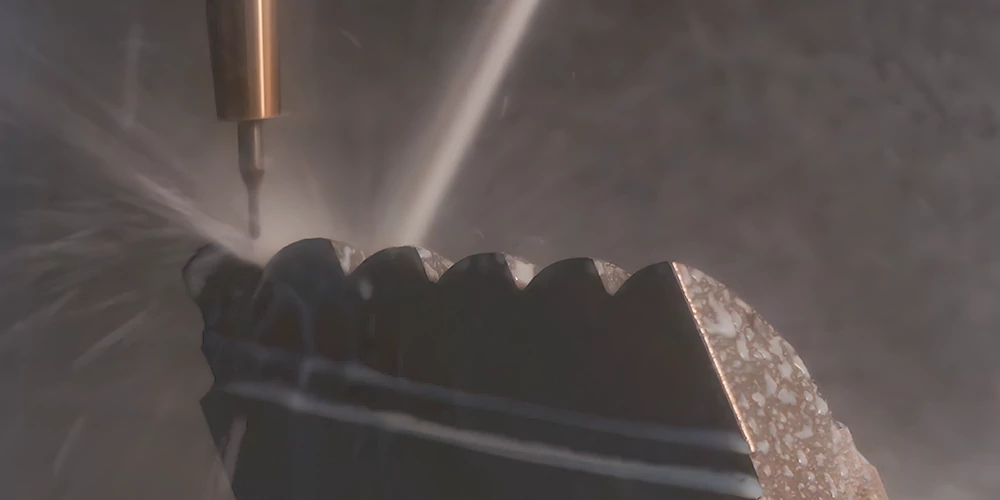

Especializados en geometrías complejas y piezas de precisión, nuestro proceso de fresado CNC es ideal para componentes como piezas de motor, bastidores y carcasas. Proporcionamos características con una precisión y un acabado superficial excepcionales utilizando fresadoras avanzadas.

Servicio de torneado CNC

Perfecto para piezas cilíndricas como ejes, varillas y casquillos, nuestro torneado CNC garantiza una alta precisión y una excelente integridad superficial. Nuestros centros de torneado son expertos en la manipulación de diversos materiales, produciendo piezas con tolerancias estrechas y acabados suaves.

Materiales mecanizados por nuestros servicios CNC

En nuestros servicios de fabricación CNC, manejamos una amplia gama de materiales, atendiendo a las necesidades específicas de nuestros clientes. Además, ofrecemos la posibilidad de buscar en el mercado el material perfecto para cada aplicación.

De plástico: Utilizando nuestras capacidades de mecanizado CNC de precisión, el plástico es una opción popular para desarrollar prototipos. Este proceso permite una evaluación exhaustiva de su producto, lo que le permite evaluar su diseño y funcionalidad a fondo.

Metal: La versatilidad de nuestros servicios de mecanizado CNC es más evidente cuando se trabaja con metales. Podemos mecanizar una gran variedad de metales, ideales tanto para el desarrollo de prototipos como para la creación de piezas finales para fabricación.

Otros materiales: Además de plásticos y metales, nuestras soluciones de mecanizado CNC a medida se extienden a una amplia gama de aleaciones y otros materiales especializados, según las peticiones de nuestros clientes.

Plásticos comunes con los que trabajamos

ABS, ABS+PC, PC, PP, PEEK, POM, acrílico (PMMA), teflón, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE.

Metales comunes con los que trabajamos

Aluminio, latón, cobre, magnesio, titanio, acero inoxidable, estaño, zinc

Si el material que desea no aparece en la lista anterior, póngase en contacto con nosotros y solicite un presupuesto gratuito hoy mismo.

Normas de tolerancia de mecanizado CNC de Prototool

Nuestro servicio de fresado CNC ofrece un fresado de alta precisión con tolerancias tan ajustadas como 0,01 - 0,05 mm. Tenga en cuenta que la tolerancia depende del tipo de material utilizado y de la geometría de la pieza fresada. Para más detalles, consulte la tabla siguiente:

| Palanca de tolerancia | Gama de dimensiones totales | ||||||

| Especificaciones | <0.5 | <3 | <6 | <30 | <120 | <400 | <1000 |

| Norma de tolerancia | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Acabados superficiales de piezas mecanizadas por CNC

Según mecanizado (Ra 3,2μm / Ra 126μin)

Mecanizado liso (Ra 1,6μm / Ra 63μin)

Mecanizado fino (Ra 0,8μm / Ra 32μin)

Pulido (Ra 0,8μm / Ra 32μin)

Granallado

Cepillado + Anodizado tipo II (Brillante)

Como mecanizado + Anodizado tipo II

Revestimiento de conversión de cromatos

Óxido negro

Niquelado químico

Granallado + Anodizado tipo II (Mate)

Granallado + Anodizado tipo II (Brillante)

Cepillado + Electropulido (Ra 0,8μm / Ra 32μin)

Como mecanizado + Anodizado tipo III (Hardcoat)

Cepillado (Ra 1,2μm / Ra 47μin)

Recubrimiento en polvo

Nuestras aplicaciones de mecanizado CNC

Para la fabricación de moldes y matrices

El mecanizado CNC es fundamental para desarrollar diversos moldes, incluidos moldes de inyección de plástico, moldes de fundición a presión de alta presión, moldes de dos disparos, moldes de 2 placas y moldes de 3 placas. Gracias a su excepcional precisión, nuestras máquinas CNC pueden tallar moldes en el metal deseado con rapidez, lo que las convierte en las preferidas para el utillaje rápido o el utillaje de producción. Esta capacidad nos permite satisfacer eficazmente necesidades de utillaje diversas y complejas, en perfecta consonancia con las exigencias de la fabricación rápida.

En nuestros servicios de mecanizado CNC, podemos fabricar prototipos personalizados para una gran variedad de sectores, como piezas detalladas de automoción, como componentes de motores, dispositivos médicos complejos, como prótesis, y electrónica de consumo, como carcasas de smartphones. Nuestro mecanizado de precisión garantiza que estos prototipos sean representaciones exactas de los productos finales, ideales para pruebas y validación. El mecanizado CNC es rentable y eficaz, y permite crear prototipos rápidos y precisos en todas las fases.

Estamos especializados en la fabricación de diversos componentes aeroespaciales, como álabes de turbina, soportes de motor, piezas de tren de aterrizaje y elementos estructurales de aeronaves. Nuestras avanzadas capacidades de mecanizado se extienden también a la producción de intrincados accesorios, componentes de sistemas de control y secciones de láminas aerodinámicas. Cada pieza se elabora meticulosamente para cumplir las estrictas normas del sector aeroespacial, garantizando un rendimiento y una seguridad óptimos.

Estamos especializados en la creación de componentes como bloques de motor, engranajes de transmisión, sistemas de suspensión y mecanismos de dirección. Nuestro mecanizado de precisión también permite la producción de sistemas de escape personalizados, componentes de frenos y complejos conjuntos de válvulas. Cada pieza de automoción está diseñada para soportar los rigores del uso diario, garantizando la fiabilidad y el rendimiento de cada vehículo.

Somos expertos en la fabricación de componentes como implantes ortopédicos, instrumentos quirúrgicos y carcasas de equipos de diagnóstico. Nuestras capacidades se extienden también al mecanizado de piezas complejas para dispositivos de imagen médica, herramientas dentales y prótesis personalizadas. Cada pieza se fabrica con la máxima precisión y cuidado, cumpliendo estrictas normas médicas para garantizar la seguridad y eficacia en aplicaciones sanitarias.

Producimos con habilidad componentes para electrodomésticos, equipos deportivos como piezas de bicicleta y piezas de instrumentos musicales. Además, nuestra experiencia en mecanizado se extiende a la creación de piezas detalladas para artilugios personales, artículos de lujo, artículos deportivos, juguetes, utensilios de cocina e incluso herrajes para muebles personalizados. Cada producto se beneficia de la precisión y la garantía de calidad que aporta el mecanizado CNC.

Comprender el mecanizado CNC

Si no conoce los servicios de mecanizado CNC, aquí tiene un breve manual para empezar:

Qué es el mecanizado CNC

El mecanizado CNC, abreviatura de Computer Numerical Control Machining, es una forma de fabricar piezas utilizando ordenadores para controlar las máquinas herramienta. Es conocido por:

- Precisión: Hace piezas con mucha precisión.

- Eficiencia: Es rápido y puede hacer formas complejas con facilidad.

- Versatilidad: Se utiliza para todo, desde coches hasta sillas y barcos.

Cómo funciona el mecanizado CNC:

- Planifica la parte: Estudiamos el diseño y buscamos la mejor manera de hacerlo.

- Prepara la máquina: Programamos la máquina con las instrucciones adecuadas.

- Mecanizado: La máquina corta y da forma al material con precisión.

- Compruebe la calidad: Nos aseguramos de que cada pieza sea perfecta.

Más información sobre "Qué es el mecanizado CNC“

Por qué elegir el mecanizado CNC

El mecanizado CNC destaca por varias razones clave:

Precisión inigualable: Es increíblemente precisa, lo que la convierte en la mejor opción para industrias críticas como la aeroespacial y la de dispositivos médicos.

Velocidad y versatilidad: Ya se trate de un prototipo, un producto final o un molde, el mecanizado CNC funciona con rapidez y puede manejar diseños complejos con facilidad.

Seguridad y fiabilidad: El proceso minimiza los errores humanos, garantizando una calidad y seguridad constantes.

Amplia compatibilidad de materiales: El mecanizado CNC es adaptable y permite trabajar con una amplia gama de materiales para satisfacer las distintas necesidades de la industria.

Eficiencia para los fabricantes: Requiere poco mantenimiento y puede funcionar continuamente, lo que la convierte en una solución rentable.

Ideal para tareas complejas: Desde el fresado hasta el torneado, el mecanizado CNC es perfecto para diseños intrincados y tareas de mecanizado no convencionales.

Preguntas frecuentes sobre el mecanizado CNC

Tal vez encuentre aquí información útil sobre los servicios de mecanizado CNC

¿Cuál es la aplicación del mecanizado CNC?

El mecanizado CNC es un proceso que se utiliza para diseñar piezas de máquinas que pueden ser porotipos o estar listas para la producción en serie. Al ser uno de los procesos más populares para la fabricación a medida, puede manejar geometrías irregulares de piezas intrincadas e incluso se utiliza para producir para la producción en masa de piezas una vez que se aprueba un prototipo.

¿Qué tipo de formatos de archivo admiten para el mecanizado CNC?

Admitimos varios formatos de archivo para garantizar que siempre cumplimos los requisitos de nuestros clientes. Esto incluye formatos populares como .stp, .sldprt y .psm/.par. Además, nos aseguramos de trabajar con nuestros clientes hasta el final para que obtengan el resultado deseado diseñado a la perfección. Este es el valor que defendemos.

¿De qué tipo de equipos dispone?

En Prototool, no sólo tenemos fresado CNC de 3 y 4 ejes, sino que también tenemos servicios de fresado CNC de 5 ejes (HAAS). Todos estos servicios proporcionan excelentes resultados, excepto cuando necesita resultados de calidad más fina, sugerimos el servicio de fresado CNC de 5 ejes en lugar de los servicios de fresado de 3 o 4 ejes. Además, nuestro servicio de torneado CNC emplea una variedad de herramientas y software de última generación que garantizan que sus componentes deseados se creen con exactitud y precisión.

¿Por qué elegir el mecanizado CNC?

El mecanizado CNC ofrece muchas ventajas. Esto incluye, pero no se limita a, la exactitud, la precisión, la rapidez de entrega, la versatilidad de las soluciones, la capacidad de trabajar con una serie de materiales, y ser una solución económica en general en comparación con otras soluciones presentes en el mercado.

¿Qué determina el coste de las piezas mecanizadas con CNC?

El coste de una pieza mecanizada con CNC viene determinado por los cuatro factores siguientes. 1) el tiempo necesario para el mecanizado, 2) el tipo de material seleccionado, 3) la geometría de la pieza que se va a mecanizar y 4) el coste inicial del proyecto. Además de los requisitos indicados por el cliente, intentamos asegurarnos de que tomamos una línea de actuación que nos lleve a un bajo coste sin comprometer la calidad del producto fabricado. Para determinar el coste de su proyecto, puede solicitar un presupuesto gratuito.

¿Qué materiales pueden utilizarse en sus procesos de mecanizado CNC de precisión?

Nuestros servicios de mecanizado CNC son compatibles con una amplia gama de materiales, incluidos diversos metales como aluminio, acero y titanio, así como plásticos como ABS, policarbonato y PEEK. Seleccionamos los materiales en función de los requisitos y aplicaciones específicos de su proyecto.

¿Cómo garantiza la precisión y la calidad en sus operaciones de fabricación y fresado CNC?

Garantizamos la calidad y la precisión mediante rigurosos procesos de control de calidad, que incluyen inspecciones periódicas y el uso de herramientas de medición de precisión. Nuestros cualificados maquinistas y avanzados equipos CNC son clave para mantener un alto nivel en cada proyecto.

¿Sus instalaciones están preparadas para gestionar pedidos de producción CNC a gran escala?

Sí, nuestras instalaciones están equipadas para gestionar pedidos de producción tanto a pequeña como a gran escala. Disponemos de una gama de máquinas CNC capaces de satisfacer diversas demandas de producción, garantizando la entrega puntual de los pedidos al por mayor.

¿Cuáles son los plazos de entrega estándar para completar proyectos de fresado CNC?

Los plazos de entrega varían en función de la complejidad y el volumen del pedido. Normalmente, los proyectos pequeños pueden completarse en una semana, mientras que los pedidos más grandes o complejos pueden tardar varias semanas. Siempre nos esforzamos por cumplir sus plazos y podemos ofrecer servicios acelerados cuando sea necesario.

¿Cómo gestiona su servicio de mecanizado CNC los diseños complejos y las geometrías intrincadas?

Nuestras avanzadas máquinas CNC, junto con nuestra experiencia en programación y mecanizado, nos permiten manejar diseños complejos y geometrías intrincadas. Trabajamos en estrecha colaboración con nuestros clientes para garantizar el cumplimiento de sus especificaciones, independientemente de su complejidad.

¿Cuál es el protocolo para modificaciones o cambios durante un pedido de mecanizado CNC?

Siempre que es posible, aceptamos modificaciones o cambios. Si es necesario realizar cambios una vez iniciada la producción, analizaremos las implicaciones en cuanto a plazos y costes y trabajaremos con usted para encontrar la mejor solución.

¿Existen directrices de diseño específicas para optimizar las piezas para sus procesos de mecanizado y fresado CNC?

Sí, recomendamos ciertas prácticas de diseño para optimizar el mecanizado CNC, como minimizar las geometrías complejas, evitar las paredes muy finas y tener en cuenta las limitaciones de acceso a las herramientas. Estaremos encantados de proporcionarle directrices detalladas para garantizar un mecanizado eficiente y eficaz de sus piezas.