Servicios de utillaje de producción

- Moldes para series de producción

- Garantizar la coherencia de las piezas con los métodos científicos

- Análisis exhaustivo de los moldes

- Proceso CMM automatizado propio con informes pertinentes

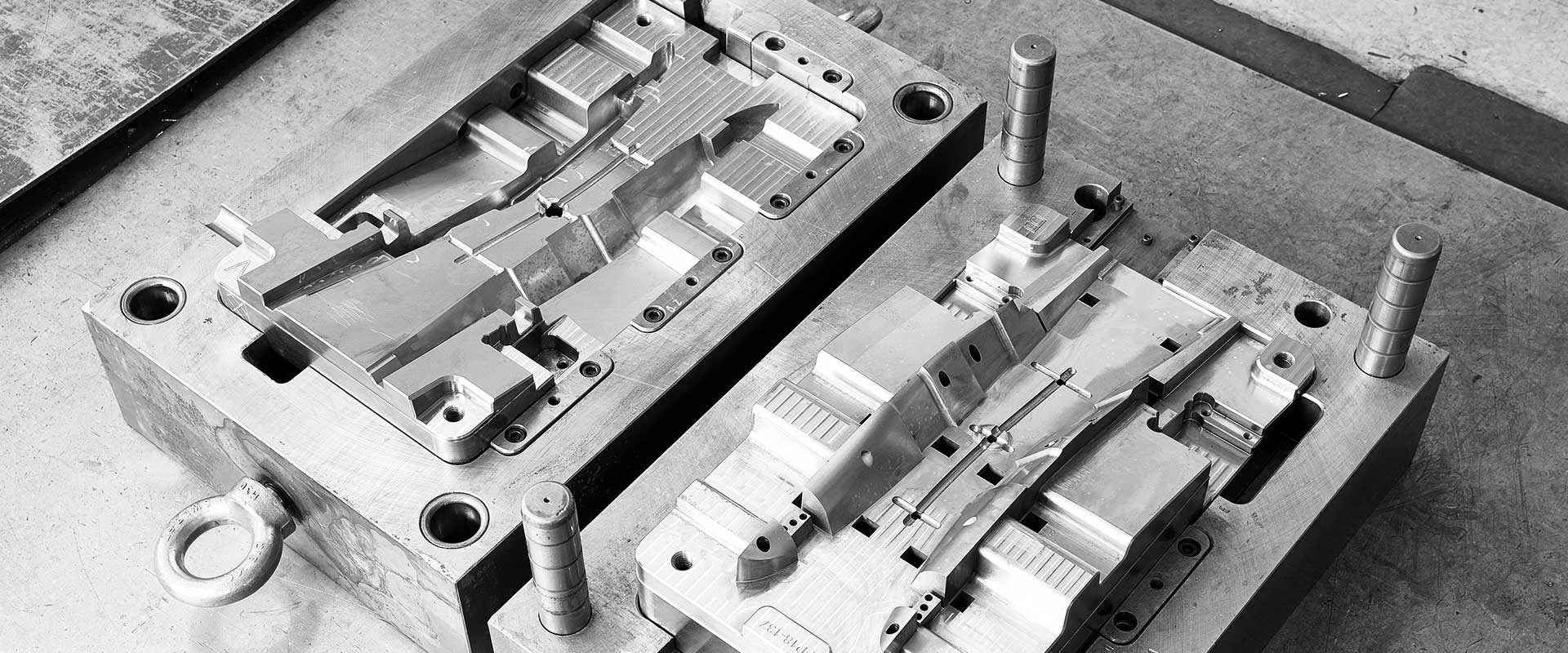

La fabricación de moldes de producción de Prototool es el proceso ideal para la fabricación bajo demanda de moldes de producción de alta calidad en poco tiempo. Dominamos una gran variedad de técnicas de moldeo, que van desde el acero hasta una gran variedad de permite y otros metales resistentes, y le ayudamos a desarrollar moldes que permitan la producción en serie. Se trata de un proceso fundamental para lograr resultados fiables. Comprendemos los complejos requisitos que hay detrás de la fabricación de un molde de producción fiable y tenemos en cuenta todas y cada una de las limitaciones que separan a un fabricante experimentado de un fabricante aficionado. Tenga la seguridad de que el producto final cumplirá sus requisitos.

Solicite hoy mismo un presupuesto gratuito y reciba su molde prototipo lo antes posible.

por qué elegirnos

Amplia gama de moldes

Desde CNC hasta otras formas de fabricación de moldes de producción, ofrecemos una variedad de herramientas y procesos de producción que creemos que cumplen todos los requisitos que nuestros clientes nos piden. Podemos desarrollar moldes que le permitan imprimir más de muchos millones de productos finales sin que se deteriore el molde ni la pieza producida.

Entrega rápida

Somos conscientes de que los mercados son muy competitivos y llegar los primeros al mercado puede marcar la diferencia. Por eso, nuestro competente equipo de ingenieros y técnicos está siempre listo para entregar sus moldes en plazos ajustados, garantizando al mismo tiempo que la calidad nunca se vea comprometida con un acceso más rápido al mercado.

Informes DFM

¿Necesita un informe de diseño para la fabricación (DFM)? Podemos ayudarle. A pesar de comprobar la viabilidad del diseño antes de la producción, ofrecemos un informe DFM rápido para proporcionar una opinión experta que le permita reconsiderar los defectos de su diseño. El informe incluye la identificación de fallos y errores de diseño que pueden causar problemas en la fabricación.

Moldes de alta calidad

Antes de poner su producto en producción, debe asegurarse de que el molde se mantiene firme en las condiciones de prueba. Para ello, necesita moldes de alta calidad que somos conocidos por fabricar y suministrar.

Por qué elegirnos

La industria del mecanizado rebosa de innumerables empresas de moldeo. Pero tenemos algunas razones de peso para que nos confíe sus proyectos de moldeo (ya sean moldes de inyección de plástico o moldes para servicios de fundición a presión). He aquí por qué:

Amplia gama de moldes

Desde CNC hasta otras formas de fabricación de moldes de producción, ofrecemos una variedad de herramientas y procesos de producción que creemos que cumplen todos los requisitos que nuestros clientes nos piden. Podemos desarrollar moldes que le permitan imprimir más de muchos millones de productos finales sin que se deteriore el molde ni la pieza producida.

Entrega rápida

Somos conscientes de que los mercados son muy competitivos y llegar los primeros al mercado puede marcar la diferencia. Por eso, nuestro competente equipo de ingenieros y técnicos está siempre listo para entregar sus moldes en plazos ajustados, garantizando al mismo tiempo que la calidad nunca se vea comprometida con un acceso más rápido al mercado.

Informes DFM

¿Necesita un informe de diseño para la fabricación (DFM)? Podemos ayudarle. A pesar de comprobar la viabilidad del diseño antes de la producción, ofrecemos un informe DFM rápido para proporcionar una opinión experta que le permita reconsiderar los defectos de su diseño. El informe incluye la identificación de fallos y errores de diseño que pueden causar problemas en la fabricación.

Moldes de alta calidad

Antes de poner su producto en producción, debe asegurarse de que el molde se mantiene firme en las condiciones de prueba. Para ello, necesita moldes de alta calidad que somos conocidos por fabricar y suministrar.

Proceso de fabricación de moldes

La fabricación de moldes de producción es un proceso complejo que requiere la experiencia de técnicos e ingenieros altamente cualificados. Un procedimiento estándar para la fabricación de moldes de producción incluye los siguientes pasos:

Análisis de fabricabilidad

El primer paso es el análisis de la fabricabilidad del molde de producción. Si se puede fabricar, nos pondremos manos a la obra de inmediato; de lo contrario, proporcionaremos nuestro informe DFM al cliente.

Diseño y análisis de flujos

A continuación, empleamos el uso de software de modelado predictivo que nos ayuda a determinar si el molde se comportará como debería o no. Realizamos todos los cambios y mejoras necesarios para asegurarnos de que así sea.

Fabricación de moldes

El siguiente paso consiste en fabricar el molde propiamente dicho con el material deseado por el cliente. Para este paso, se utilizan máquinas y equipos de alta calidad para producir un molde que funcione según lo previsto con el material para el que se va a utilizar.

Muestreo

Se fabrican muestras a partir del molde para asegurarse de que el producto final se ajusta a los requisitos del cliente o si es necesario modificarlo.

Envío

Cuando nuestros ingenieros están satisfechos con el producto final, se envía al cliente. Después, nos mantenemos en contacto con el cliente para asegurarnos de que está satisfecho con el producto que ha recibido.

Ofrecemos el mejor servicio del sector

Moldes de fundición a presión

Adecuados tanto para prototipos como para producción en serie, los moldes de fundición a presión están hechos de acero endurecido, lo que los hace muy resistentes y fiables. En ellos se puede utilizar una gran variedad de materiales y aleaciones para la producción a gran escala.

Molde de inyección de metal

Es una forma de moldeo por inyección en la que la materia prima consiste en metal y aglutinante. Fabricado con acero para herramientas de alta calidad, está diseñado para resistir la inyección de metal. Otros sustitutos son el aluminio. Es muy popular para la fundición de moldes de producción.

Molde de fundición al vacío

La fundición en vacío es un método utilizado para fabricar prototipos o piezas de alta calidad en volúmenes reducidos sin ningún coste de utillaje. Este método permite aprovechar las ventajas de la velocidad, la precisión, el tamaño, el coste e incluso el volumen.

Técnicas de moldeo de producción disponibles

¿Qué nos hace destacar?

Equipo profesional

Al ofrecer una amplia gama de moldes de producción, somos una de las empresas de fabricación de moldes más destacadas en la que confían una gran variedad de clientes que creen en nuestras capacidades. Nuestro equipo fuerte y capaz de ingenieros han satisfecho las necesidades de cientos de profesionales de la industria antes y podemos hacer lo mismo para usted.

Precisión y exactitud

Hemos proporcionado a los profesionales de la industria moldes de producción con un alto grado de precisión, exactitud y tolerancia limitada. Además, garantizamos la resistencia y funcionalidad de nuestras piezas.

Multimateriales

Estamos especializados en la fabricación de moldes de producción adecuados para una amplia gama de metales y aleaciones, por lo que le ayudaremos a identificar el tipo de molde adecuado para sus necesidades de producción en serie. Puede contar con nosotros para fabricar sus productos finales exactamente como desea.

Industrias que utilizan moldes de producción

Hay una gran variedad de industrias que dependen de los moldes de producción para la fabricación en serie del producto final. Esto incluye

Preguntas frecuentes sobre la fabricación de moldes y herramientas de producción

Información clave sobre los servicios de fabricación de moldes y herramientas de producción

¿Cuál es la vida útil típica de un molde de producción?

La vida útil de un molde de producción depende del material y también de cuántas piezas se produzcan. Pero lo más habitual es que los moldes puedan utilizarse durante cientos de miles de ciclos, sobre todo si están fabricados con acero endurecido o aluminio duradero.

¿Cómo garantizar la precisión en la fabricación de moldes de producción?

Los moldes de producción son instrumentos de precisión que requieren mecanizado CNC y estrictas medidas de control de calidad para su fabricación. Todos los moldes que producimos son dimensionalmente precisos gracias al uso de equipos de última generación.

¿Qué materiales son los más adecuados para los moldes de producción de gran volumen?

Los que se utilizan para la producción de moldes de gran volumen están fabricados con materiales duraderos, como acero endurecido o aluminio, que pueden soportar el ciclo repetido de las operaciones de fabricación.

¿Son adecuadas las herramientas de producción para geometrías complicadas?

Absolutamente. Nuestras rigurosas técnicas de utillaje de producción pueden adaptarse a geometrías especiales para que, en cualquier circunstancia, el artículo moldeado no deje de cumplir los requisitos de diseño.

¿Cuánto tiempo se tarda en fabricar moldes de producción a medida?

El plazo de entrega para la fabricación de moldes de producción personalizada depende de la minuciosidad de cada caso concreto y de la carga de trabajo actual. Proporcionamos el servicio más rápido posible sin afectar a las instrucciones de calidad.

¿Existe algún límite para los tamaños de las herramientas de producción?

En los utillajes de producción, las limitaciones de tamaño se basan en las capacidades de nuestros equipos. Podemos aceptar una amplia gama de tamaños de moldes y encontraremos el que mejor se adapte a sus necesidades.

¿Cómo se realiza el control de calidad de las herramientas de producción?

En el caso de los moldes de producción, el proceso de garantía de calidad incluye una inspección en profundidad y pruebas según las normas del sector. Cada molde debe ser capaz de producir piezas de alta calidad repetidamente.

¿Son adecuados los moldes de producción para plásticos y metales?

Los moldes de producción se utilizan para piezas de plástico, pero muchos metales requieren procesos de fabricación diferentes (como la fundición a presión o el mecanizado CNC).

¿Cómo se diseña un molde de producción a medida?

La fabricación de un nuevo molde de producción a medida requiere un estudio minucioso de la pieza, la composición del material y la cantidad que se va a producir. Empleamos software CAD para diseñar moldes con especificaciones diseñadas exactamente según sus requisitos.

¿Ofrecen producción rápida de prueba antes de completar el utillaje?

Claro, y podemos hacer prototipos rápidos para comprobar el diseño de la pieza y saber si se adapta a sus necesidades antes de mecanizarla para la producción.

¿Es posible modificar los moldes de producción después de la fabricación inicial?

Los moldes de producción pueden modificarse, pero sólo hasta cierto punto. Para algunos diseños pueden bastar ligeras alteraciones; para otros puede ser necesario hacer un molde completamente nuevo.

¿Cuánto cuesta la fabricación de moldes?

El coste varía en función del tamaño y la complejidad de los moldes, los materiales utilizados, la finura requerida para aplicaciones específicas, etc.