Blogs

El mundo del mecanizado de piezas diversas está lleno de conocimientos importantes. Incluso Prototool, que lleva más de diez años en el sector del mecanizado, tiene mucho que aprender e innovar. Todo lo que tenemos que hacer es tranquilizarnos y disfrutar nadando en el mar del conocimiento.

Diseño de jefes: Elementos clave, directrices de diseño, problemas comunes y soluciones

Comprender el diseño de patrones en el moldeo por inyección, centrándose en los elementos clave, las directrices de diseño y las soluciones de piezas moldeadas de plástico.

Leer más >>Estrategias para diseñar con éxito productos con los materiales adecuados

Hablemos del papel de la selección de materiales en el diseño de productos, centrándonos en la colaboración con los moldeadores para obtener productos estéticamente agradables.

Leer más >>Dominar la precisión: Una inmersión profunda en la inspección dimensional en el moldeo por inyección

El artículo se centra en la función clave de la inspección dimensional en el moldeo por inyección y analiza el uso de tipos de equipos para la medición.

Leer más >>Dominar los agujeros ciegos y pasantes en el diseño

Explore los agujeros ciegos y los agujeros pasantes en esta guía dirigida específicamente a profesionales que deseen mejorar sus habilidades en el diseño de piezas.

Leer más >>Ventajas del moldeo de palets de plástico

Descubra el moldeo de plástico para paletas de plástico, que ha convertido la fabricación en una tecnología avanzada con características de diseño mejoradas.

Leer más >>Diseño de moldes para engranajes de plástico

Descubra las peculiaridades del diseño de moldes para engranajes de plástico y sus características clave y técnicas de fabricación especializadas.

Leer más >>Pasos generales en el diseño de productos sanitarios y el desarrollo de productos

Descubra las etapas clave del diseño de dispositivos médicos y el desarrollo de productos, garantizando la calidad y el cumplimiento de estrictas normativas.

Leer más >>Creación de espacio estratégico en el diseño de moldes

Explore los pasos esenciales para la holgura estratégica en el diseño de moldes de plástico, garantizando el mecanizado eficiente, el montaje y la longevidad de los moldes.

Leer más >>Factores que afectan al coste o precio del prototipo

Descubra los factores clave que afectan a los costes de los prototipos rápidos. Una guía concisa para entender y estimar los precios de los prototipos rápidos.

Leer más >>Recubrimiento en polvo frente a pintura en el tratamiento de superficies de prototipos

Descubra las principales diferencias entre el revestimiento en polvo y la pintura en prototipos, incluidos los métodos de aplicación, la rentabilidad, etc.

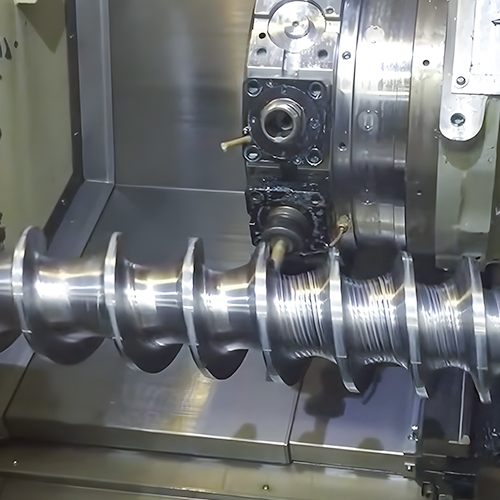

Leer más >>Cómo gestionan los defectos de mecanizado las principales fábricas de mecanizado CNC

Este artículo muestra cómo los mejores proveedores abordan los defectos de mecanizado CNC, revelando las formas en que sus piezas de alta calidad se someten a superar los desafíos.

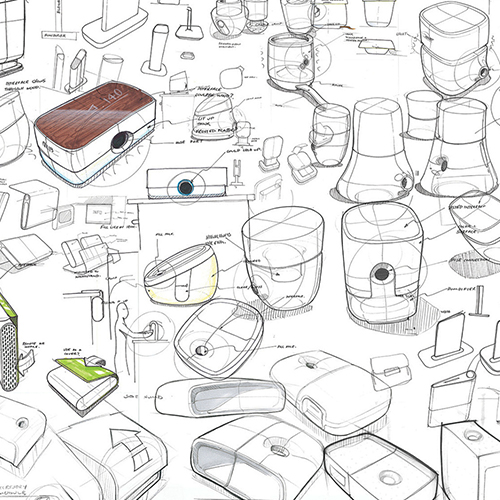

Leer más >>El ABC del diseño de estilo de producto En el diseño industrial

Explore el mundo de la estilización de productos en el diseño industrial. Da lugar a productos únicos, funcionales y estéticamente atractivos.

Leer más >>Como principiante, ¿qué software de diseño de productos debo elegir?

Compare el software de diseño de productos, desde CAID y Rhino hasta CATIA y SolidWorks, y sus funciones únicas en el diseño estético y estructural.

Leer más >>Principios generales del diseño de piezas de plástico para moldeo por inyección

Los diseñadores de productos experimentados conocen a fondo los procesos de moldeo por inyección y tienen en cuenta numerosos factores en el diseño de piezas de plástico. Este artículo se centra en elementos esenciales como el grosor de la pared, los ángulos de desmoldeo, las nervaduras, los orificios, los pilares, los broches, los ajustes de interferencia y las tolerancias en las piezas moldeadas de plástico....

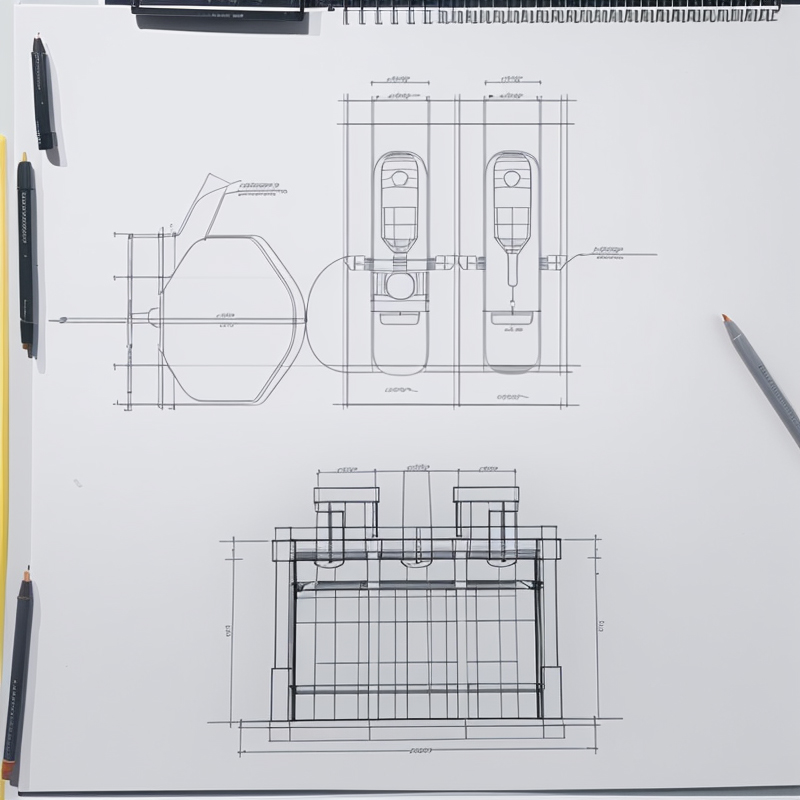

Leer más >>¿Qué fundamentos son necesarios para un excelente diseño estructural de productos?

El diseño estructural de productos se refiere al proceso de diseño de los aspectos físicos de los productos, como dispositivos digitales y electrodomésticos, una vez conceptualizada su apariencia externa. Cómo entender la definición de "diseño estructural de productos" Esta fase de diseño...

Leer más >>Pasos para desarrollar un producto de éxito

Pasos para desarrollar con éxito un producto, desde la generación de la idea hasta la evaluación posterior al lanzamiento, adaptados a empresarios y gestores de productos.

Leer más >>Precisión en el fresado por penetración: Geometría de la herramienta y parámetros de corte esenciales

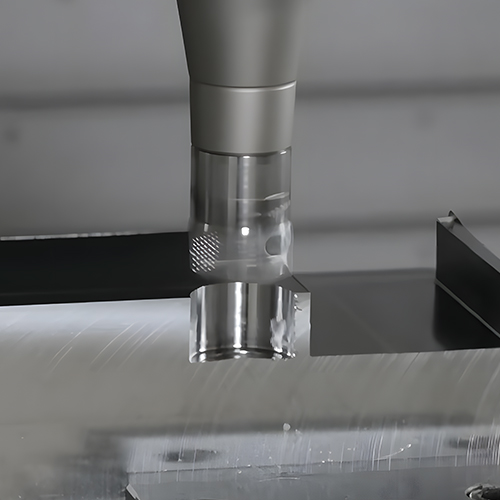

Si ya está familiarizado con el mecanizado básico, el fresado por penetración es como añadir una potente herramienta a su caja de herramientas. A diferencia del corte normal, que se realiza alrededor de los bordes, las operaciones de fresado por penetración se realizan justo en el extremo de la herramienta. Ahora bien, ¿por qué...

Leer más >>Técnicas estratégicas para operaciones eficientes de fresado periférico

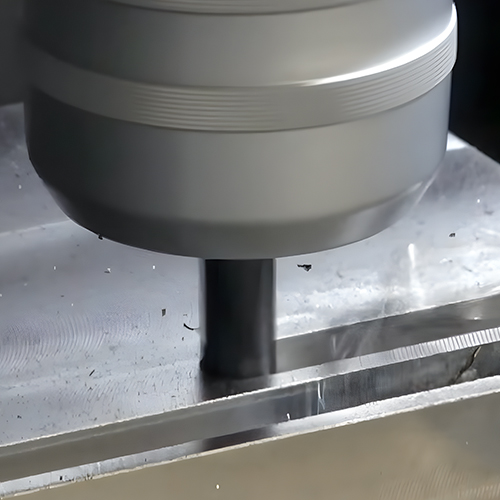

El fresado periférico es una operación de mecanizado crucial empleada por fabricantes intermedios y profesionales para mejorar los índices de arranque de viruta y prolongar la vida útil de las herramientas. Esta guía explora varias estrategias, centrándose en el fresado plano, el fresado estándar y la distinción entre fresado ascendente y descendente....

Leer más >>Excelencia en el fresado lateral: Una inmersión profunda en técnicas y soluciones prácticas

Explore el fresado lateral sobre sus técnicas esenciales, selección de herramientas y soluciones prácticas para lograr precisión y eficacia en las operaciones.

Leer más >>Llevar el fresado frontal al siguiente nivel: Todo lo que necesita saber

Explore un impresionante artículo sobre el fresado frontal, que abarca desde estrategias básicas hasta avanzadas para lograr precisión en el mecanizado CNC.

Leer más >>Optimización del mecanizado CNC: Una inmersión profunda en el mundo del fresado en rampa

Cuando se considera el mecanizado de precisión, dominar las técnicas avanzadas no es sólo una habilidad, es una necesidad. Una de esas técnicas avanzadas de mecanizado CNC que debe tenerse en cuenta para satisfacer determinadas necesidades de fabricación es el "fresado en rampa". ¿Por qué es esencial? Principalmente porque...

Leer más >>Modificación del molde frente a construcción de un molde nuevo: ¿Qué elegir?

Conozca las situaciones en las que basta con modificar el molde y las situaciones que exigen un molde nuevo, junto con el coste y los pasos para modificarlo.

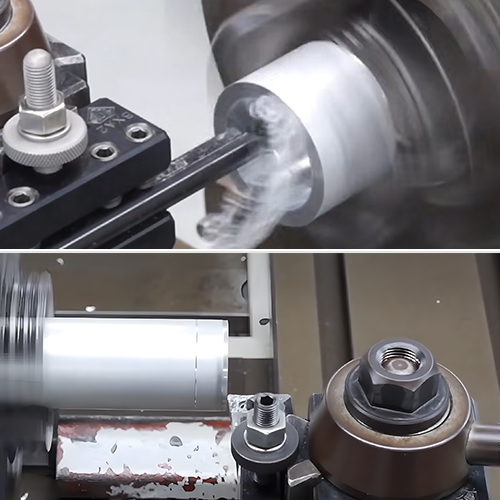

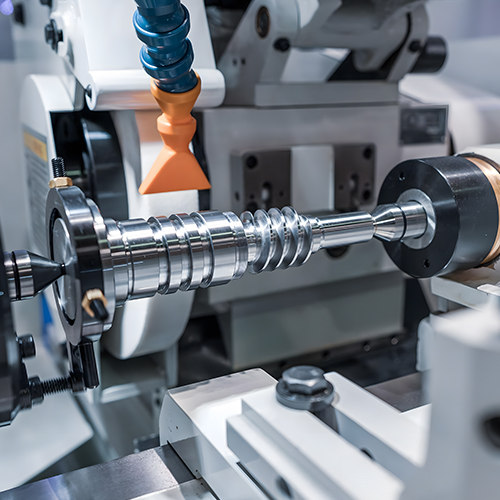

Leer más >>Torneado interior vs. Torneado exterior: Diferencias y usos

Descubra la comparación entre torneado interior y exterior a partir de los mecanismos, la selección de herramientas y las estrategias avanzadas.

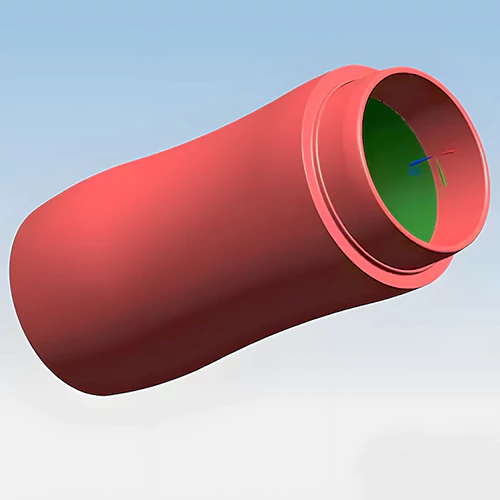

Leer más >>Más allá de lo básico: Exploración del torneado cónico avanzado en el mecanizado

Explore el torneado cónico en tornos, incluyendo cálculos, métodos y técnicas clave para conseguir piezas de alta calidad en la fabricación CNC.

Leer más >>¿Cuáles son las piezas moldeadas más comunes de los vehículos eléctricos?

Consulte la lista de piezas moldeadas habituales en vehículos eléctricos. Haga clic para saber cómo fabrican estos avanzados componentes las empresas de moldeo por inyección.

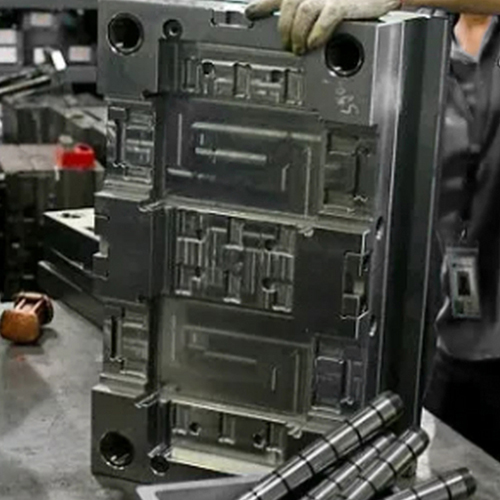

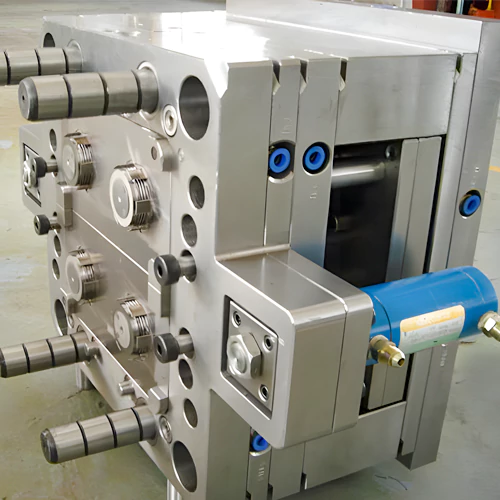

Leer más >>Los ocho tipos de moldes de inyección

Explore los tipos de moldes de inyección utilizados en la producción. Estas clasificaciones se basan en la estructura del molde de inyección.

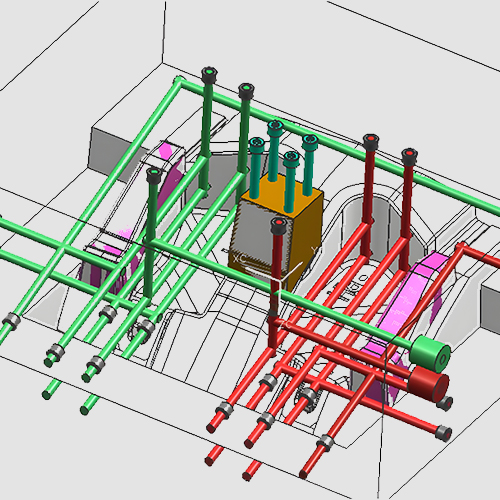

Leer más >>Principios de diseño de sistemas de refrigeración de moldes de inyección

Compruebe los principios clave para diseñar sistemas eficaces de refrigeración de moldes de inyección y vea cómo los proveedores garantizan la calidad de sus productos.

Leer más >>Análisis de los factores de agrietamiento en grandes moldes de fundición a presión

Los proveedores experimentados de fundición a presión analizan las razones del agrietamiento del molde de fundición a presión para que los productos de los clientes sean más perfectos!.

Leer más >>Comprendiendo los Pasos Completos del Cierre del Moho: Cómo prevenir los daños causados por el moho desde la raíz

Vea cómo una buena empresa de moldeo por inyección puede garantizar la calidad de producción de sus clientes' productos a través de los puntos clave del cierre de moldes.

Leer más >>Análisis del diseño del sobremoldeado de vasos en el software UG/NX

Estudiando el caso del análisis del diseño del sobremoldeado de vasos, verá cómo las buenas empresas de moldeo por inyección completan a la perfección toda la fabricación.

Leer más >>Puntos clave y análisis en el diseño de moldes de plástico para mandos a distancia

Comprenda las principales consideraciones, tecnologías innovadoras y normas en el diseño de moldes de plástico para mandos a distancia utilizadas por los principales proveedores.

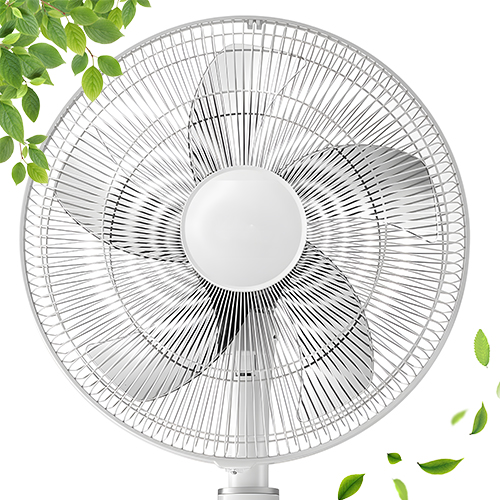

Leer más >>Puntos clave en el diseño de moldes y moldeo por inyección para las aspas de un ventilador de una conocida marca

Discover the critical aspects of fan blade mold design, including balance principles, material considerations & factory's molding techniques.

Leer más >>Análisis del diseño del molde de la carcasa de la lechera de soja

Explore soluciones expertas en diseño y producción de moldes para carcasas de fabricantes de leche de soja. Póngase en contacto con proveedores líderes expertos en la creación de moldes de alta calidad.

Leer más >>Análisis del diseño de moldes cosméticos para tapas de tarros de crema

Descubra cómo se diseñan y analizan los moldes cosméticos para tapas de tarros de crema. Conozca los detalles centrados en la belleza que son importantes a la hora de fabricar moldes.

Leer más >>Fresado helicoidal: Guía detallada

Conozca las aplicaciones del fresado helicoidal en el taladrado, el fresado de contornos y el mecanizado de roscas, y cómo mejora la precisión en el mecanizado de metales.

Leer más >>Desbloquear la precisión: El arte del superacabado en la fabricación

Conozca las aplicaciones de los superacabados, desde la industria aeroespacial a la médica, y comprenda cómo revolucionan la precisión.

Leer más >>Fundamentos del diseño de moldes: La importancia de las guías para moldes de inyección

¿Se ha preguntado alguna vez cómo se moldean a la perfección características intrincadas y complejas en piezas de plástico? La respuesta está en el fascinante mundo de las guías de moldes de inyección. Estos componentes especializados son los héroes anónimos de la creación de muescas, roscas y otras...

Leer más >>Maximizar la eficacia y la longevidad de los ciclos de vida de los moldes de inyección

¿Alguna vez se ha preguntado cuánto dura un molde de inyección? Es una pregunta complicada en la que intervienen muchos factores. No podemos predecirlo a la perfección, como no podemos predecir cuándo se averiará un coche. Pero podemos hacer una estimación. Esta...

Leer más >>Dominio de la acción lateral del molde para un moldeo de precisión

En medio de la evolución de los mercados globales y los ciclos de vida más cortos de los productos, el diseño de moldes se enfrenta a retos cada vez mayores, y la acción lateral del molde surge como una solución estratégica, especialmente cuando se trata de geometrías de piezas intrincadas o socavados difíciles. Comprender estos escenarios constituye la base...

Leer más >>Descifrando los cierres de molde: Guía completa de diseño y funcionalidad

En el cambiante mundo del moldeo por inyección, es fundamental profundizar en los matices del diseño de moldes. Los obturadores de moldes, a menudo ignorados pero cruciales, ocupan un lugar central para abordar los difíciles obstáculos de diseño y utillaje. Piense en ellos como los cerebros...

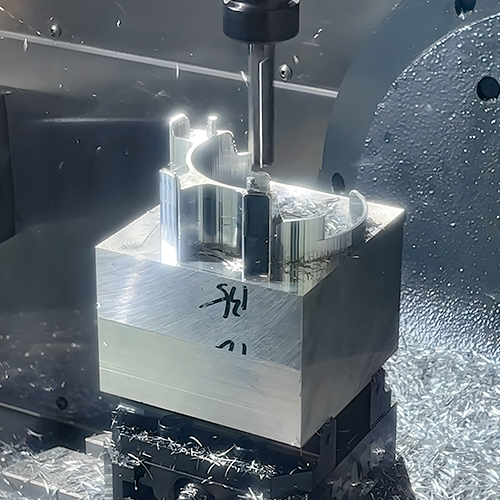

Leer más >>Puesta a punto de sus proyectos CNC: Guía para el mecanizado de acabado

El acabado superficial o mecanizado de acabado, un aspecto crítico del mecanizado, profundiza en los detalles finos del perfeccionamiento de la calidad externa y la funcionalidad de una pieza de trabajo. Este preciso proceso implica un meticuloso ajuste de la superficie, ya sea por eliminación o adición de material, para cumplir los...

Leer más >>Optimización de la producción con el semiacabado en el mecanizado

La industria manufacturera valora mucho el papel del semiacabado. Este proceso crucial consiste en refinar un producto hasta un nivel específico de acabado antes de llegar a la fase de acabado final. Es fundamental para garantizar que el producto final cumpla las especificaciones requeridas...

Leer más >>Del bruto al refinado: Exploración de los métodos de mecanizado en bruto

El mecanizado de desbaste es un proceso que consiste en eliminar rápida y eficazmente el exceso de material para acercar la pieza a su diseño final. Este enfoque de mecanizado CNC emplea herramientas de corte más grandes, realizando cortes amplios y potentes para eliminar cualquier...

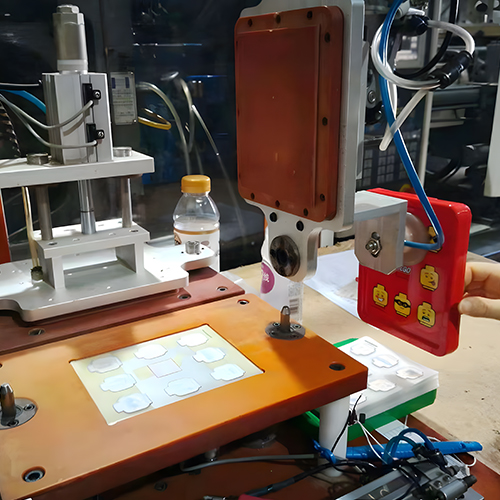

Leer más >>Tendencias del moldeo por inyección: Lo que hay que tener en cuenta en 2024

La industria del moldeo por inyección está en constante movimiento, adaptándose a las tecnologías emergentes, a la evolución de las demandas del mercado y a la creciente conciencia medioambiental. En este dinámico panorama de tendencias de la industria del moldeo por inyección, varios desarrollos clave en la industria del moldeo por inyección han tomado protagonismo....

Leer más >>El proceso de etiquetado en molde

Explore el etiquetado en molde (IML) con Prototool: un cambio radical en la producción de envases por su durabilidad, calidad y eficacia.

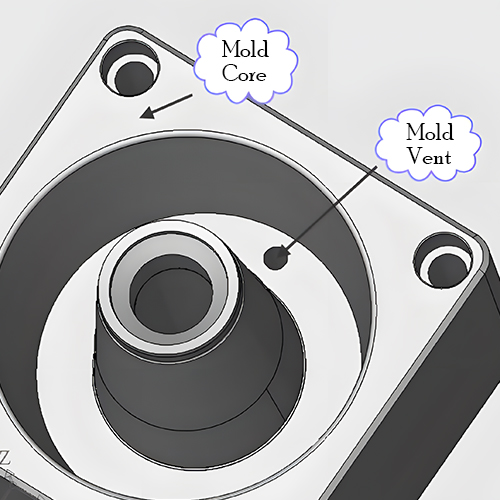

Leer más >>¿Dónde y cómo ventilar en el moldeo por inyección?

Conozca la colocación estratégica de la ventilación de moldes, los métodos y los consejos de diseño para mejorar la calidad de las piezas, proteger los moldes y aumentar la eficacia con Prototool.

Leer más >>Guía para la autodegradación en el moldeo por inyección

Explore la autodegradación en el moldeo: carreras de apertura del molde, su principio, ventajas de la compuerta de precisión, 3 consejos y comparaciones de acabado del molde.

Leer más >>Consejos esenciales para una reparación eficaz de moldes de inyección

Descubra cuándo y cómo reparar un molde de inyección, parámetros de mantenimiento cruciales, una guía de reparación en 8 pasos y 4 ventajas principales.

Leer más >>