Servicios de moldeo por inyección

Nuestros servicios de moldeo por inyección especializados en servir a clientes globales durante más de una década

- Solución integral de diseño y fabricación

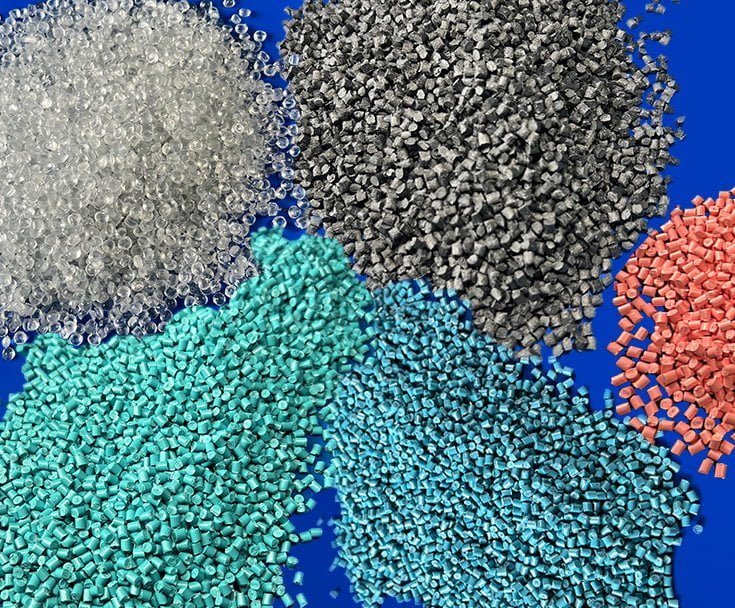

- Más de 100 opciones de materiales y colores

- Alta eficacia y plazos más cortos

- Fuerza de sujeción de hasta 1000T

Certificaciones: IATF16949:2016 | ISO9001:2015

Una buena fábrica de moldeo por inyección debe tener una rica experiencia, equipos bien equipados, personal profesional en todos los puestos, cultura corporativa orientada al cliente y buena conciencia de servicio.

Sí, Prototool es la mejor empresa para usted. Nuestros servicios de moldeo por inyección llevan más de diez años dando servicio a una amplia gama de sectores, como el de la automoción, la cosmética, los bienes de consumo y muchos otros. Basándonos en nuestra experiencia, entendemos lo que más desea cada cliente cuando entabla una colaboración integral de moldeo por inyección con nosotros.

¿Por qué elegir Prototool para el moldeo por inyección?

Más de 10 años Servicio profesional integral

En nuestros servicios de moldeo de plásticos contamos con un equipo experimentado y apasionado. Garantizan un producto final de alta precisión, desde el diseño y la creación del molde inicial hasta el proceso de fabricación y la entrega segura en su ubicación.

Más de 100 y materiales personalizados a elegir

PPS, PP, POM, ABS, C-GF, HDPE, LDPE, PBT, TPV, PC, POE, PMMA, PA66, PA-GF, PS-PPE, TPE, TPU y más. Valoramos inmensamente las necesidades comerciales de nuestros clientes, por lo que también podemos procesar los materiales de moldeo por inyección proporcionados por los clientes.

Moldeo de alto calibre a precios asequibles

Aunque no pretendamos ofrecer los servicios de moldeo por inyección más baratos del mundo, le aseguramos que nuestros precios representan la mejor relación calidad-precio. Durante la última década, hemos trabajado incansablemente para mejorar la calidad de los productos de nuestros clientes. Este compromiso implica mejorar la precisión de nuestras máquinas de moldeo por inyección, aprender continuamente sobre materiales nuevos y modificados, y aplicar estos conocimientos de forma práctica para ofrecer resultados excepcionales.

Capacidades de fabricación interna de vanguardia

Nuestra experiencia en moldeo por inyección está respaldada por más de 100 máquinas avanzadas con fuerzas de cierre de hasta 1000T. Estamos comprometidos a mantenernos a la vanguardia de la tecnología, invirtiendo continuamente en nuestros equipos; este plan de inversión continua es un testimonio de nuestra dedicación a la excelencia en el moldeo por inyección. Nuestras capacidades internas se extienden al diseño de moldes personalizados, la especialización en materiales, la creación rápida de prototipos, las líneas de producción automatizadas, la rigurosa garantía de calidad, las completas opciones de acabado, la producción de grandes volúmenes y las prácticas respetuosas con el medio ambiente.

Colabore con nosotros para sus necesidades de moldeo por inyección

Inicie su propio proyecto

Empiece por solicitar un presupuesto con una descripción completa y un dibujo técnico en 3D de su producto para nuestros servicios de moldeo por inyección de precisión. Nuestros ingenieros están a su disposición tanto si se trata de un diseño complejo como de una pieza sencilla: ¡usted es lo primero!

Análisis DFM y presupuesto gratuitos

Intentamos responder en un plazo de 24 horas. Tras recibir su solicitud, nos tomaremos el tiempo necesario para realizar un estudio exhaustivo de DFM con nuestro correspondiente presupuesto sobre los servicios de moldeo por inyección personalizados que se adaptan especialmente a usted.

Fabricación de moldes y moldeo

Una vez que apruebe el presupuesto y se nos informe de su depósito, nuestro personal preparará las máquinas y comenzará con la fabricación del diseño del molde. Después de eso, comenzaremos la producción de moldeo por inyección para sus proyectos.

Tratamiento posterior y entrega fiable

Todas sus piezas moldeadas por inyección se embalan bien, se etiquetan adecuadamente y se le envían directamente a tiempo. Compruebe lo eficaces y fiables que son nuestro procesamiento mecánico y nuestra garantía de calidad.

Servicio de moldeo por inyección eficiente, rentable, duradero y de alta precisión

Somos los mejores de su clase en moldeo por inyección. ¡Pídanos ahora! Usted encontrará que bien vale la pena cuando se va a utilizar nuestros productos y que sin duda aportará valor a su negocio.

Nuestras opciones avanzadas de moldeo por inyección

Podemos producir miles de piezas para acelerar el ciclo de desarrollo de su producto. Puede elegir entre una gran variedad de materiales. Mantenemos más de 100 materiales de resinas plásticas en el inventario para poner en marcha la producción. Para los productos finales moldeados, tenemos muchas opciones de acabado. Nuestras capacidades de moldeo por inyección son el moldeo de plástico, el moldeo por inserción, el sobremoldeo y el moldeo familiar.

Empleamos los mejores materiales termoplásticos para producir piezas moldeadas por inyección de calidad superior. Ejecutamos científicamente todo el proceso, desde la recopilación de requisitos hasta la evaluación del diseño, la producción de moldes y matrices y el producto final.

En el moldeo por inserción, utilizamos una pieza prefabricada (generalmente de metal) que se inserta en un molde. Para obtener el producto final, el molde preformado se sobremoldea con la resina termoplástica necesaria. Aprovechando nuestros servicios de moldeo por inserción, puede obtener productos de calidad excepcional.

En el proceso de sobremoldeo, podemos moldear un material termoplástico en un segundo material termoplástico o caucho de silicona líquido. Esto nos permite conseguir los atributos y la funcionalidad requeridos para el producto.

Cuando el cliente exige entregas rápidas de los proyectos, recurrimos al molde de inyección familiar. Nos permite fabricar varias piezas con el mismo material en un solo ciclo. Esta técnica de moldeo por inyección tiene más de una cavidad cortada en el molde. Cada cavidad puede fabricar una pieza diferente.

Opciones de materiales para servicios de moldeo por inyección

Podemos procesar numerosos plásticos y polímeros. Tenemos capacidad interna de una gran colección de diferentes materiales de moldeo por inyección. Esto incluye PPS, PP, POM, ABS, C-GF, HDPE, LDPE, PBT, TPV, PC, POE, PMMA, PA66, PA-GF, PS-PPE, TPE y TPU. También podemos procesar materiales suministrados por los clientes.

Diferentes opciones de acabado superficial

Con varias opciones de acabado de superficies, Prototool puede hacer que sus productos moldeados por inyección tengan mejor aspecto y funcionen mejor. Se pueden elegir distintos métodos de acabado según las necesidades. A continuación se indican algunas de las técnicas que utilizamos para perfeccionar sus piezas moldeadas por inyección:

Granallado

El granallado es una forma de limpiar y refinar las piezas moldeadas por inyección. Utiliza perlas de vidrio o acero a alta presión para granallar la superficie y conseguir un acabado uniforme y mate. Es un buen método si desea un aspecto uniforme y profesional.

Tampografía

El proceso de tampografía multifuncional es excelente para aplicar logotipos de empresa y nombres de marca, así como todo tipo de diseños decorativos, a la superficie de productos moldeados por inyección. Es una buena opción si lo que busca es una personalización propia y aumentar el atractivo de sus piezas.

Grabado

Para aumentar la rugosidad de las piezas moldeadas por inyección, se utiliza nuestro método de grabado superficial. Por medios químicos o físicos, podemos crear la textura y el acabado que satisfagan sus necesidades.

Acabado láser

Las piezas moldeadas por inyección pueden someterse a un tratamiento superficial con láser. Se trata de un proceso térmico muy exigente. Graba con gran precisión finas líneas e imágenes, firmes eslóganes de empresa o pequeños logotipos. Puede calentar hasta varios cientos de grados centígrados absorbiendo la luz en su capa superficial.

Aplicación industrial del moldeo por inyección

Debido a sus propiedades favorables a la fabricación, el moldeo por inyección se está aprovechando en muchos sectores del mundo. Se emplea en casi todas las industrias de una u otra forma.

Marina

Robótica

Petróleo y gas

Transporte

Mercancías generales

Nuestras capacidades de moldeo por inyección

Contamos con décadas de experiencia en la fabricación de piezas moldeadas por inyección. Hemos servido a numerosas industrias. Estamos cumpliendo con las necesidades de diversas industrias no a nivel local, sino también a nivel mundial con nuestro firme compromiso de ofrecer la excelencia a través de nuestros servicios y generar valor para nuestros clientes.

Máquinas bien equipadas y avanzadas

Seguimos actualizando nuestras máquinas con los últimos modelos para ser un nombre líder en este sector. Nuestro departamento de I+D trabaja muy duro en investigación y desarrollo. Para que podamos prosperar en el servicio a nuestros clientes y ayudarles a alcanzar sus objetivos de negocio.

Servicios rápidos

Cuando alguien se pone en contacto con nosotros para adquirir nuestros servicios, indagamos los requisitos del cliente y le proponemos las mejores opciones. Tras la aprobación, un equipo especializado formado por diseñadores, ingenieros, técnicos y expertos en control de calidad empieza a trabajar inmediatamente en el proyecto. Garantizan producciones de calidad en los plazos previstos.

Excelente durabilidad y eficacia

Máquinas bien equipadas y avanzadas

Preguntas frecuentes sobre los servicios de moldeo por inyección

Obtenga información esencial sobre Servicios de moldeo por inyección que puede resultar muy valiosa para sus necesidades.

¿Cómo puedo saber si el servicio de moldeo por inyección es adecuado para mi empresa o no?

Si no está seguro de si este servicio se adapta a las necesidades de su empresa. No se preocupe. Póngase en contacto con nosotros. Le preguntaremos sus necesidades y el uso de su producto. Después de hacer la evaluación, le haremos saber si el moldeo por inyección es adecuado para usted o no.

¿Qué capacidades de moldeo por inyección tienen?

Estamos excepcionalmente capacitados para prestar servicios de moldeo por inyección fiables y eficaces. Nuestro estado de la maquinaria de arte y un equipo experimentado nos hace un jugador líder en este campo. Nuestras capacidades de moldeo por inyección son moldeo de plástico, moldeo por inserción, sobremoldeo y moldeo familiar.

¿Cuánto tarda en completarse el proceso de moldeo por inyección?

El tiempo necesario para completar el proceso de moldeo por inyección suele depender de la disponibilidad de material, la complejidad del diseño, la calidad de la superficie requerida, etc., y los requisitos del cliente. Pero, por lo general, se tarda entre 7 y 10 días en completar el proyecto.

¿Qué materiales se pueden utilizar en el moldeo por inyección?

Trabajamos con una amplia gama de materiales de moldeo por inyección, como ABS, policarbonato, polipropileno y resinas más especializadas como PEEK y TPE.

¿Pueden ayudarnos con el diseño de piezas para moldeo por inyección?

Sí, ofrecemos asistencia en el diseño de piezas para garantizar que sus diseños estén optimizados para el moldeo por inyección, centrándonos en factores como el grosor de las paredes, el diseño de las nervaduras y la colocación de las compuertas.

¿Cuál es la cantidad mínima de pedido para el moldeo por inyección?

Nuestra cantidad mínima de pedido depende del proyecto específico. Atendemos tanto producciones pequeñas como grandes, y ofrecemos flexibilidad para satisfacer las necesidades de nuestros clientes.

¿Ofrecen prototipado rápido para proyectos de moldeo por inyección?

Sí, ofrecemos servicios de prototipado rápido para ayudarle a validar sus diseños antes de pasar a la producción a gran escala.

¿Cómo garantiza la calidad de sus piezas moldeadas por inyección?

Empleamos estrictas medidas de control de calidad, que incluyen inspecciones periódicas y el uso de herramientas de medición avanzadas, para garantizar que cada pieza cumple las especificaciones exigidas.

¿Puede producir piezas complejas e intrincadas con el moldeo por inyección?

Absolutamente. Nuestra avanzada tecnología de moldeo por inyección nos permite producir piezas con geometrías complejas y detalles intrincados.

¿Qué opciones de acabado existen para las piezas moldeadas por inyección?

Ofrecemos varias opciones de acabado, como pintura, chapado, serigrafía y tampografía, para mejorar el aspecto y la funcionalidad de las piezas.

¿Cuáles son las tolerancias típicas alcanzables con su proceso de moldeo por inyección?

Nuestro proceso de moldeo por inyección puede conseguir tolerancias muy ajustadas, normalmente de +/- 0,005 pulgadas, en función del material y del diseño de la pieza. Garantizamos una alta precisión en cada pieza para satisfacer sus requisitos específicos.

¿Cómo se abordan las socavaduras en las piezas moldeadas por inyección?

Utilizamos técnicas avanzadas como acciones laterales, elevadores o insertos cargados a mano para gestionar eficazmente las socavaduras en piezas moldeadas por inyección, garantizando que las geometrías complejas se produzcan con precisión.