Servicios de prototipado rápido

Pruebas de entrada en el mercado con servicios de prototipado rápido

- Su socio para servicios fiables de prototipado rápido

- Más de 12 años y 2000 tipos de piezas de metal y plástico procesadas

Nuestros servicios de prototipado rápido proporcionan a los clientes prototipos de productos y máquinas de alta calidad. Utilizamos diversas técnicas y materiales adaptados a sus necesidades. Con nuestra experiencia, puede asegurarse un prototipado eficaz y preciso.

Por qué elegir Prototool

Estos son algunos valores fundamentales del prototipado rápido que tendrá en nuestro servicio.

Experiencia a nivel internacional

Contamos con un equipo de expertos con 12 años de experiencia en la prestación de servicios de fabricación a nivel internacional. Pueden ofrecerle servicios de primera categoría en prototipado rápido.

Precios asequibles

¿Le preocupa el presupuesto para la creación rápida de prototipos? No tiene por qué preocuparse, ya que le proporcionaremos los servicios a un precio asequible. Ofrecemos un coste competitivo que merece la pena.

Fácil de usar

Con nuestro servicio, recibirá la entrega rápidamente, en la puerta de su casa. Recibirá sus productos sin dificultad ni molestias.

Opciones ilimitadas

El prototipado rápido le ofrece muchas opciones diferentes para su pedido. Puede acceder a ellas mientras realiza el pedido. Entre ellas se incluyen el material, la tolerancia, el acabado y las marcas.

Nuestro proceso de trabajo

Este es el orden de trabajo típico que puede esperar cuando nos contrata para nuestros servicios de fundición a presión:

Enviar solicitud

Envíe su solicitud de presupuesto gratuito con una descripción y un dibujo técnico de su producto. Si no dispone de dibujo técnico, no se preocupe. Podemos realizar ingeniería inversa.

DFM y presupuesto

Solemos responderle en un plazo de 24 horas.

Creación de prototipos

Una vez que apruebe el presupuesto y realice el depósito, utilizaremos los equipos y materiales más modernos para iniciar el trabajo que refleje fielmente el diseño.

Perfeccionamiento

Probaremos a fondo el prototipo para asegurarnos de que cumple sus especificaciones. En función de sus comentarios y de los resultados de las pruebas, haremos los ajustes necesarios.

Llámenos ahora para obtener el mejor servicio de prototipado rápido

Método de mecanizado para la creación rápida de prototipos

Utilizamos principalmente dos métodos frecuentes según los requisitos de nuestros productos.

1

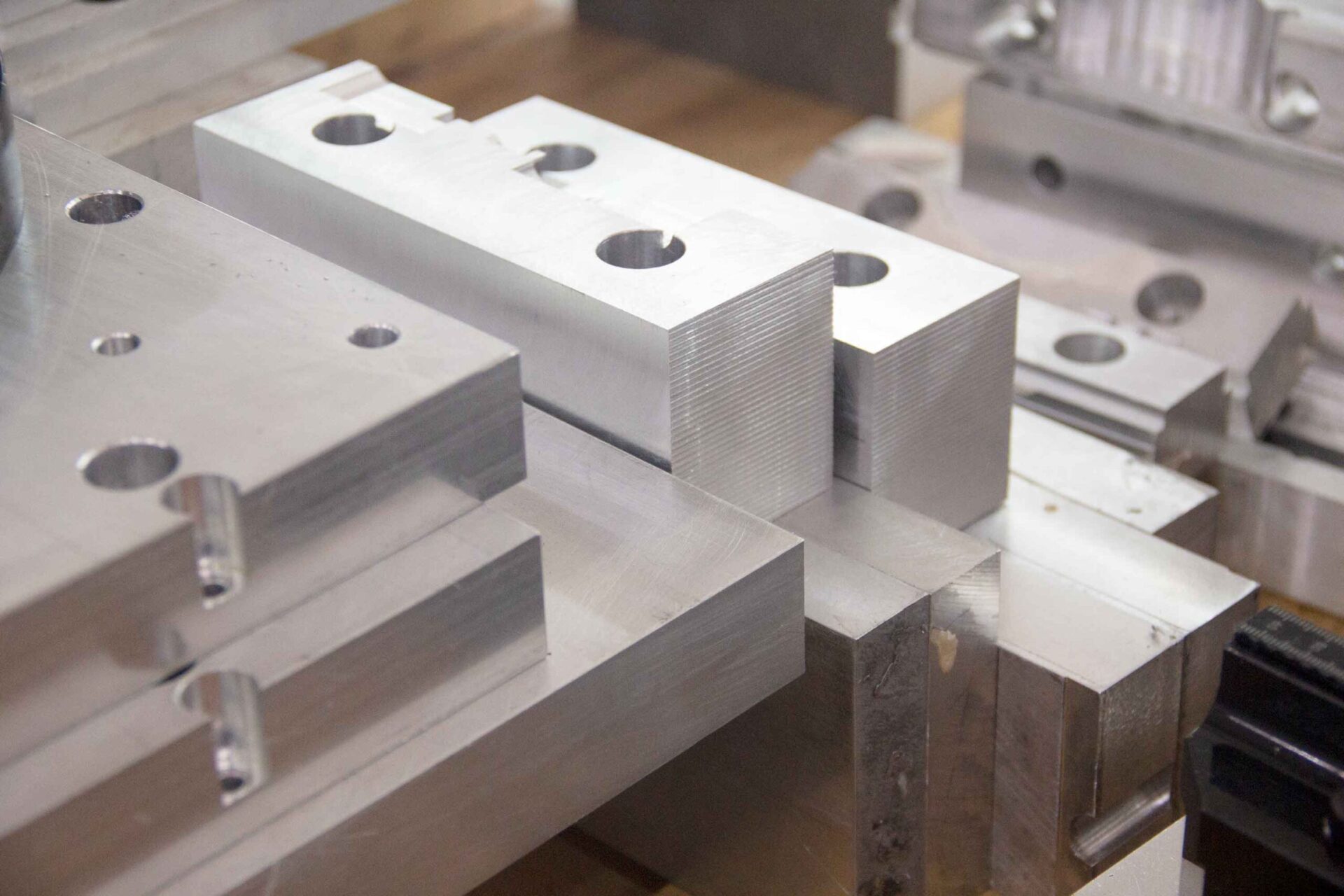

CNC MECANIZADO RP

Ofrece velocidades de procesamiento rápidas, costes bajos y gran precisión de procesamiento. Con una amplia gama de selección de materiales, pueden garantizar la coherencia entre el material del modelo hecho a mano y el material de las piezas producidas en serie.

2

PROTOTIPO DE COLADA AL VACÍO

Utiliza PU líquido como material, que ofrece características similares al ABS, PC y otros plásticos. Este proceso es ideal para pequeñas cantidades de unos 10-100 juegos de productos de plástico y es rentable con un ciclo de producción más corto.

Creación rápida de prototipos en diversos materiales

Una vez exportados sus prototipos rápidos, es necesario buscar una empresa de prototipado rápido de confianza que pueda gestionar una gran variedad de materiales y sea capaz de conservar todo el proyecto de prototipado inmediato en una sola área. En este sentido, somos una excelente elección. Podemos crear piezas prototipo a partir de plásticos, metales y cerámica.

Plásticos

Ofrecemos una amplia gama de materiales plásticos para la creación rápida de prototipos, como ABS, PC, PMMA, PA, POM y PP, entre otros. Nuestro equipo cuenta con una amplia experiencia en la selección del material adecuado para cada proyecto, lo que garantiza el mejor rendimiento y rentabilidad para sus prototipos.

Metales

Ofrecemos una gran variedad de materiales metálicos para la creación rápida de prototipos, como aluminio, acero inoxidable, latón y cobre, entre otros. Cada material metálico tiene sus propias propiedades, como resistencia, ductilidad y conductividad térmica, lo que nos permite crear piezas con distintos requisitos funcionales.

Tolerancia para nuestros prototipos rápidos

Rectitud: Los niveles de tolerancia pueden oscilar entre 0,05 mm y 0,5 mm, en función de la longitud de la característica y la tecnología utilizada.

Planitud: Los niveles de tolerancia pueden oscilar entre 0,05 mm y 0,5 mm, en función del tamaño de la característica y de la tecnología utilizada.

Redondez: Los niveles de tolerancia pueden oscilar entre 0,05 mm y 0,5 mm, en función del diámetro del elemento y de la tecnología utilizada.

Cilindricidad: Los niveles de tolerancia pueden oscilar entre 0,05 mm y 0,5 mm, en función del diámetro y la longitud del elemento y de la tecnología utilizada.

Tratamiento de superficies

- Pintura

- Revestimiento

- Anodizado

- Chorro de arena

- Recubrimiento en polvo

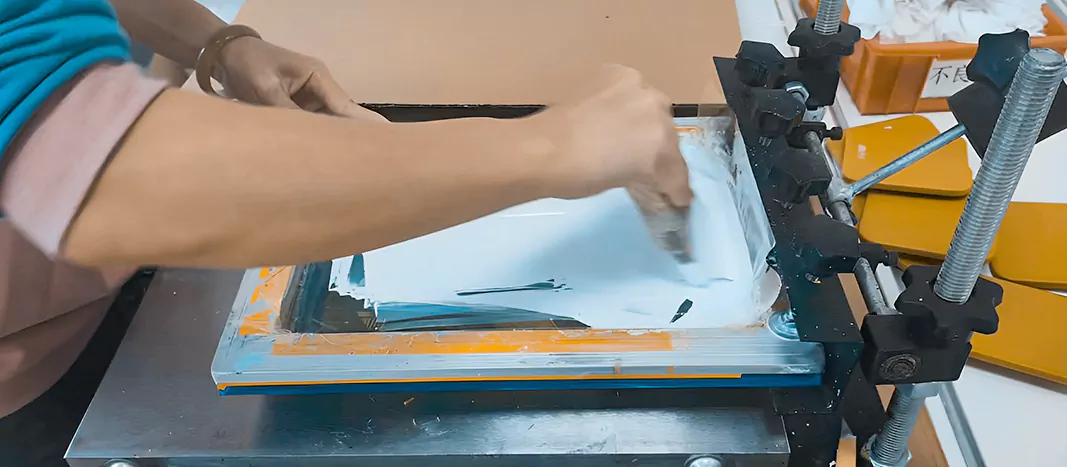

- Serigrafía

Automoción | Aeroespacial | Médico | Electrónica de consumo | Equipamiento industrial |

|---|---|---|---|---|

Componentes del motor | Álabes de turbina | Prótesis | Fundas de teléfono | Engranajes |

Prototipos de cuadros de mando | Componentes estructurales | Guías quirúrgicas | Carcasas de portátiles | Válvulas |

Carcasas de luz | Piezas de motor prototipo | Implantes dentales | Teclados | Sistemas de transporte |

Conductos de aire | Ortesis | Rejillas de altavoz | Piezas de bombas |

Galerías

Preguntas frecuentes sobre los servicios de prototipado rápido

información sobre los servicios de RAPID PROTOTYPING para sus proyectos

¿En cuánto tiempo puedo recibir un prototipo con sus servicios de prototipado rápido?

Nuestros prototipos rápidos suelen entregar las piezas en unos pocos días, dependiendo de la complejidad y del método elegido. La impresión 3D suele producir piezas en 24-48 horas, mientras que el mecanizado CNC puede tardar unos días más.

¿Qué información necesitan para proporcionar un presupuesto de prototipado rápido?

Para obtener un presupuesto de creación acelerada de prototipos, facilítenos archivos CAD 3D detallados, especificaciones de materiales y cualquier requisito específico de acabado. Cuanto más detallada sea su información, más preciso será nuestro presupuesto.

¿Puede producir prototipos funcionales que imiten los materiales del producto final?

Sí, con nuestras avanzadas técnicas de creación de prototipos, podemos crear prototipos funcionales utilizando materiales que se asemejan mucho a los del producto final, especialmente en el mecanizado CNC.

¿Cuál es el tamaño máximo que puede manejar para la fabricación de prototipos?

El tamaño máximo para la fabricación de prototipos depende del método elegido. En el caso de la impresión 3D, está limitado por el tamaño de la impresora, mientras que el mecanizado CNC puede adaptarse a tamaños mayores. Indique las dimensiones concretas para obtener una respuesta precisa.

¿Sus servicios de prototipado rápido son adecuados para geometrías complejas?

Por supuesto. Nuestro prototipado exprés, en particular la impresión 3D, destaca en la producción de geometrías complejas que podrían ser difíciles o imposibles de conseguir con la fabricación tradicional.

¿Puedo hacer cambios en el diseño después de ver el prototipo inicial?

Sí, una de las ventajas de nuestros servicios de creación rápida de prototipos es la posibilidad de realizar cambios en el diseño después de revisar el prototipo inicial. Podemos iterar rápidamente para perfeccionar el diseño.

¿Cómo se compara el coste de la creación rápida de prototipos con el de la fabricación tradicional?

La creación rápida de prototipos puede ser más rentable para pequeñas cantidades, ya que elimina la necesidad de costosas herramientas y los costes de preparación asociados a la fabricación tradicional.

¿Pueden utilizarse los prototipos rápidos para las pruebas de carga y estrés?

Sí, podemos fabricar prototipos con materiales adecuados para las pruebas de esfuerzo y carga, especialmente con el mecanizado CNC, que puede utilizar una amplia gama de materiales duraderos.

¿Cuál es el nivel de detalle que puede alcanzarse con sus métodos de creación de prototipos?

Nuestros avanzados métodos de creación de prototipos, especialmente la impresión 3D de alta resolución, permiten obtener detalles finos y características complejas, idóneos para diseños y aplicaciones intrincados.

¿Qué formatos de archivo son necesarios para la creación de prototipos mediante CNC e impresión 3D?

Normalmente aceptamos formatos de archivo CAD como STL, STEP e IGES tanto para prototipos CNC como para impresión 3D.

¿Cómo se determina el mejor método de creación de prototipos para mi proyecto?

Evaluamos factores como la complejidad del diseño, los requisitos de material, el acabado deseado y el uso previsto del prototipo para recomendar el mejor método, ya sea mecanizado CNC, impresión 3D o una combinación.

¿Se puede pasar de la creación de prototipos a la producción?

Sí, podemos ayudarle a pasar del prototipo a la producción en serie. Proporcionamos información y apoyo en la transición de su proyecto a la fabricación en serie.