Servicios de moldeo por inyección de plásticos

Los servicios de moldeo por inyección de plásticos más aplicados

- Plazos de entrega rápidos

- Más de 100 materiales para elegir

- Estricto sistema de control de calidad

- Producción a la carta

Certificaciones: IATF16949:2016 | ISO9001:2015

Prototool se especializa en el moldeo por inyección de plásticos, con una década de experiencia que puede ayudarle a evitar retos comunes como la capacidad insuficiente, la capacidad de diseño incierta, la calidad inestable del producto y la entrega a destiempo. Nuestra experiencia se extiende a diversas industrias, como la automoción, la aeroespacial, la electrónica de consumo y la médica. Nuestro equipo de moldeo por inyección, formado por más de 50 profesionales, incluidos diseñadores, programadores, operarios y supervisores de calidad, trabaja a la perfección con nuestro equipo de moldes para ofrecer resultados excepcionales. Nuestro dedicado y creativo equipo ha prestado sus servicios con éxito a cientos de clientes de todo el mundo, obteniendo siempre una respuesta positiva.

Por qué elegirnos

Equipo experimentado

- Más de 500 proyectos entregados mensualmente

- Más de 10 años de experiencia en el sector

- Más de 100 técnicos de alto nivel

Entrega rápida

- Tan rápido como 7 días

- Servicio DFM gratuito

- Presupuesto instantáneo en 24 horas

Control de precisión

- Más de 10 socios de Fortune 500

- Certificación IATF:16949, ISO9001:2015

- Equipo y equipos de control de calidad

Servicio interno

- Más de 80 equipos importados

- 30.000 ㎡ de planta moderna

- Rentabilidad y calidad superior

Global Agility, Localized Excellence

At Prototool, our dual-base injection molding facilities in China and Mexico empower your projects with unparalleled flexibility and compliance. Whether you’re scaling production or navigating regional tariffs, we deliver high-quality, cost-optimized plastic parts tailored to your market.

- Tariff-Smart Production: Choose between our China or Mexico bases to manufacture closer to your target markets, minimizing import duties and logistics costs.

- Speed Meets Precision: Leverage Mexico’s rapid prototyping and high-volume capabilities for North American markets—ideal for just-in-time delivery.

Nuestros magníficos clientes

¿Busca servicios de moldeo por inyección de plásticos de alta calidad?

Cómo trabajar con nosotros

El proceso de moldeo por inyección de plástico puede parecer sencillo, pero hay muchos parámetros que deben controlarse estrictamente para garantizar la calidad y consistencia de los componentes de plástico producidos.

Enviar solicitud

Para obtener un presupuesto gratuito, adjunte a su solicitud una descripción del producto y un dibujo técnico. ¿No dispone de un dibujo técnico? No hay problema. También ofrecemos servicios de ingeniería inversa.

DFM y presupuesto

Nuestro plazo de respuesta habitual es de 24 horas. Sin embargo, tenga en cuenta que el proceso de comunicación puede requerir conversaciones continuas, y todo el proceso es totalmente gratuito.

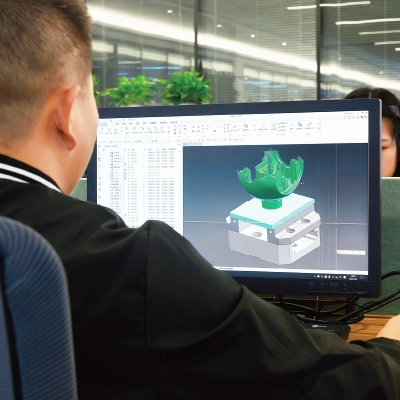

Fabricación de moldes

Una vez aprobado el diseño, empezaremos a fabricar el molde para sus piezas de plástico. Nuestro equipo utilizará tecnología y equipos avanzados para fabricar un molde de alta calidad que cumpla sus especificaciones.

Moldeo por inyección

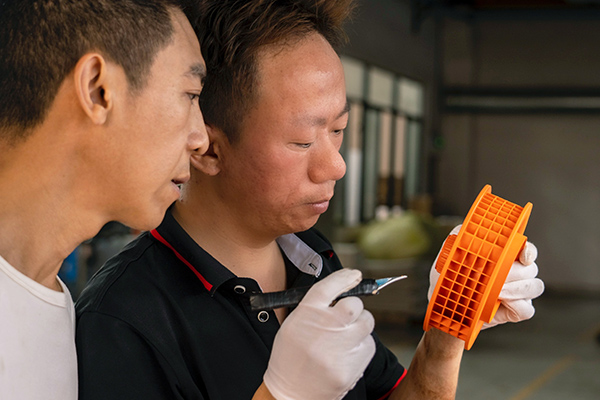

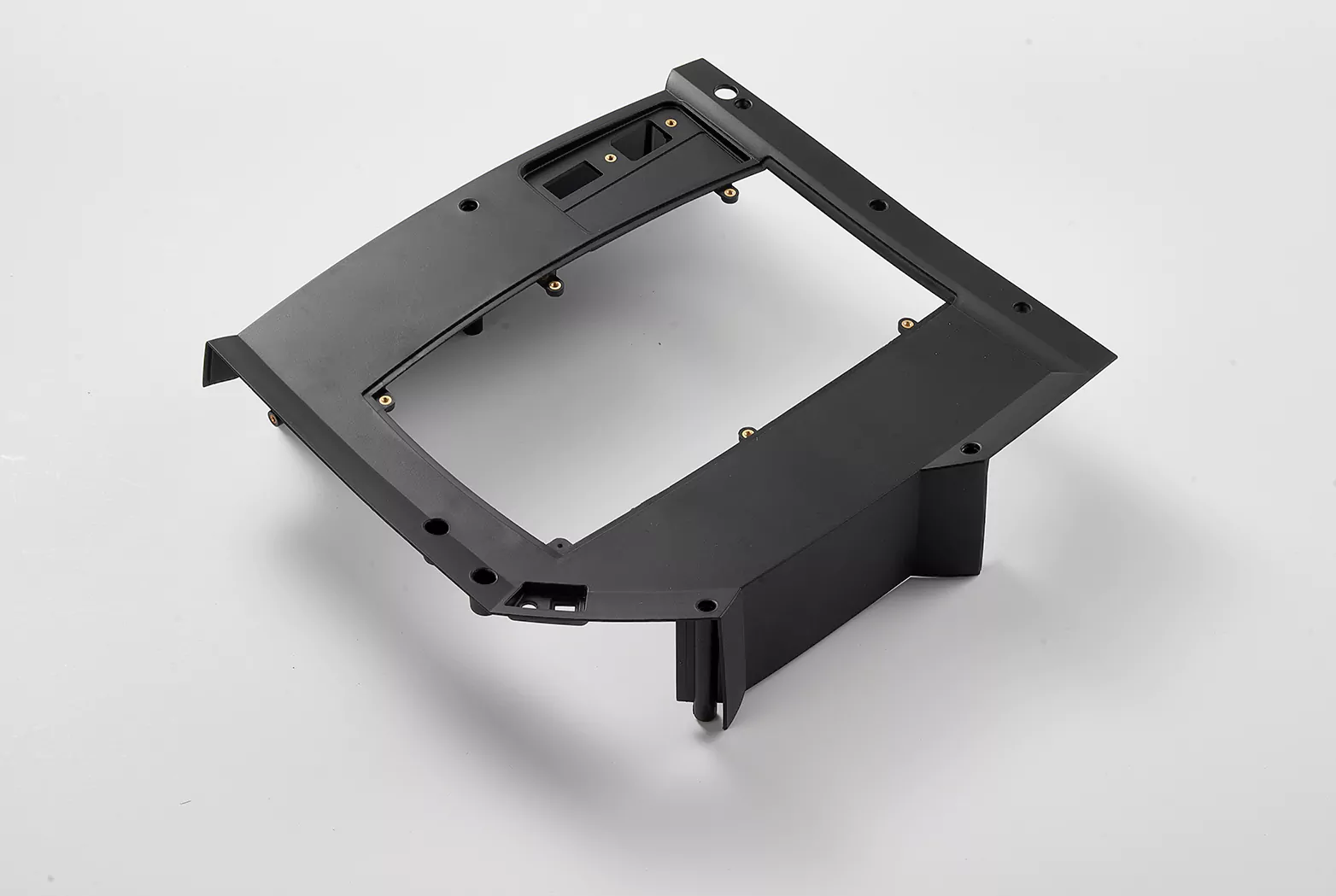

Una vez que el molde esté listo, comenzaremos el proceso de moldeo por inyección. Nuestros técnicos cualificados utilizarán el molde para crear piezas de plástico de alta calidad con formas y tamaños uniformes. Realizaremos comprobaciones de control de calidad durante todo el proceso.

Tolerancia

Los factores que afectan a la tolerancia de las piezas moldeadas por inyección incluyen las propiedades del plástico, el diseño del producto, el diseño del molde, el proceso de moldeo por inyección, etc. Cuando hablamos de tolerancias de productos moldeados por inyección, es mejor tener en cuenta el aspecto y la función del producto acabado y el coste.

Normalmente, Prototool toma DIN 16742 como nuestra norma de tolerancia de moldeo por inyección, y para la industria del automóvil, cumplimos la QC-T-29017-1991 Norma de tolerancia de la industria del automóvil como nuestra norma. Cuando el cliente tiene requisitos especiales de tolerancia, seguimos estrictamente los requisitos.

El proceso de moldeo por inyección de plásticos

1.Sujeción

El núcleo y la cavidad son las dos piezas principales de un molde de inyección. En el primer paso, durante la sujeción, estas dos partes del molde serán extruidas y encajadas por la máquina.

2. Inyección

3. Vivienda

A continuación viene la fase de envasado, en la que el plástico fundido se llena hasta la totalidad del molde mediante presión. La presión se aplica directamente al molde de forma que el líquido llene todas las cavidades del molde y el producto salga con precisión y sea idéntico al molde.

4.Refrigeración

Este paso del proceso permite que transcurra el tiempo necesario para que el molde se enfríe. Si este paso se realiza demasiado deprisa, los productos pueden pegarse o deformarse al desmoldarlos.

5. Apertura del molde

Se trata del proceso inverso a la sujeción. En este paso, un motor de sujeción abre lentamente las dos partes del molde para garantizar la seguridad y la estabilidad.

6. Expulsión

Materiales utilizados para el moldeo por inyección de plásticos

ABS

ABS/PC

Acetal

Delrin

ETPU

HDPE

LCP

LDPE

LLDPE

Polipropileno

CCE

PPE/PS

PS

FUENTE DE ALIMENTACIÓN

TPU

Acabado

Ofrecemos múltiples opciones de acabado para completar los productos de plástico fabricados con el proceso de moldeo por inyección de plástico. Puede elegir entre cualquiera de las siguientes opciones en función de los requisitos de su aplicación:

Acabado estándar

Acabado interior, no cosmético, según la geometría del molde.

Acabados SPI

Gama de acabados SPI desde grado 3 diamante / pulido alto hasta 320 piedra pulido bajo. Estas opciones de acabado incluyen SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2 y SPI D-3.

Insertos roscados

Podemos instalar los insertos estándar más utilizados y populares en tamaños UNF y métricos.

Como moldeado

Como su nombre indica, el molde permanecerá "tal cual", sin texturas secundarias ni pulido.

Texturizado de moldes

Creación de texturas en los moldes para que se vean en el producto final. Esta opción de acabado incluye mate, remolinos, patrones y líneas.

Grabado por láser

Grabe números de pieza, diseños, logotipos o cualquier otra impresión especificada en sus piezas.

Tampografía

Aplicación de un diseño a base de tinta sobre la superficie.

Pintura

Pintura de la superficie con colores estándar o Pantone a juego, incluyendo imprimación y capa de acabado. Enmascaramiento disponible; pintura EMI (cobre).

Aplicación industrial

Los servicios de Moldeo por Inyección de Plástico que ofrecemos tienen una gran variedad de aplicaciones en todos los sectores, incluyendo:

Aeroespacial y defensa

Automoción

Productos de consumo

Servicios de diseño

Educación

Electrónica y semiconductores

Médico y dental

Energía

Nuevas empresas de hardware

Industrial

Robótica

Cadena de suministro y compras

Nuestros puntos fuertes

Industry Expertise & Guidance

Nuestro equipo de expertos en moldeo por inyección de plásticos está a su disposición para elaborar un plan de éxito para la creación de prototipos, la validación de diseños y las aplicaciones de producción.

Herramientas de producción

Ofrecemos utillaje de producción a todos nuestros clientes con soluciones rentables y rápidas.

Diseños complejos y personalizados

Realizamos tolerancias estrictas y dibujos en 2D para una amplia variedad de sectores. No importa la complejidad ni la personalización, podemos hacerlo realidad para usted.

Preguntas frecuentes sobre el moldeo por inyección de plásticos

Obtenga respuestas sobre Servicios de moldeo por inyección de plásticos que podrían ser esenciales para sus necesidades particulares.

¿Cómo puedo obtener un presupuesto para servicios de moldeo por inyección de plástico?

Para recibir un presupuesto, facilítenos información detallada sobre su proyecto, incluidos los diseños o planos de las piezas, las especificaciones de los materiales y la cantidad de piezas necesarias. También debe mencionar cualquier requisito adicional, como el acabado o el montaje.

¿Qué tipos de materiales plásticos pueden utilizarse en el moldeo por inyección?

Trabajamos con una amplia gama de materiales termoplásticos, como ABS, policarbonato, polipropileno y resinas más especializadas como PEEK y TPE, en función de los requisitos de resistencia, flexibilidad y resistencia térmica de la pieza.

¿Cuál es la cantidad mínima de pedido para el moldeo por inyección de plástico?

Nuestra cantidad mínima de pedido varía en función del proyecto. Nos adaptamos tanto a lotes pequeños como a grandes series, por lo que ofrecemos flexibilidad para satisfacer las distintas necesidades de los clientes.

¿Pueden ayudarnos con el diseño de piezas para moldeo por inyección?

Sí, ofrecemos asistencia en el diseño de piezas para garantizar que sus diseños se optimizan para el moldeo por inyección. Esto incluye asesoramiento sobre el grosor de las paredes, el diseño de los nervios y la colocación de las compuertas para una fabricación eficiente.

¿Existen limitaciones de diseño en el moldeo por inyección de plásticos?

Las restricciones de diseño incluyen consideraciones sobre el flujo del molde, la expulsión de la pieza y la refrigeración. Los diseños deben evitar los destalonamientos, mantener un grosor uniforme de las paredes y tener en cuenta los ángulos de desmoldeo para facilitar la expulsión de las piezas.

¿Puede producir piezas de alta precisión con tolerancias estrictas?

Sí, nuestro proceso de moldeo por inyección de plástico es capaz de producir piezas de alta precisión con tolerancias muy ajustadas. Utilizamos maquinaria avanzada y rigurosos controles de calidad para garantizar la precisión.

¿Qué opciones de acabado existen para las piezas moldeadas por inyección?

Ofrecemos varias opciones de acabado, como pintura, chapado, serigrafía y texturizado, para mejorar el aspecto y la funcionalidad de las piezas moldeadas por inyección.

¿Cómo se garantiza la calidad de las piezas moldeadas por inyección?

La calidad se garantiza mediante un estricto control de los procesos, inspecciones periódicas y el cumplimiento de las normas del sector. Realizamos varias pruebas para verificar la precisión dimensional, las propiedades de los materiales y la calidad general de cada pieza.

¿Cómo se garantiza la confidencialidad de los diseños patentados en los proyectos de moldeo por inyección?

Nos tomamos muy en serio la confidencialidad de los diseños de nuestros clientes. Utilizamos prácticas seguras de tratamiento de datos y podemos suscribir acuerdos de confidencialidad para proteger la información de su propiedad.

¿Cómo gestionan los proyectos de moldeo por inyección de tiradas cortas o volúmenes reducidos?

Para proyectos de tiradas cortas o de bajo volumen, ofrecemos opciones de producción flexibles y podemos utilizar soluciones de utillaje más rentables para que el proceso sea viable y eficaz para cantidades más pequeñas.

¿Ofrecen análisis del flujo del molde durante la fase de diseño?

Sí, realizamos análisis del flujo del molde para simular el proceso de moldeo por inyección, lo que ayuda a optimizar el diseño del molde y a garantizar la calidad de la pieza final.

¿Cómo se garantiza la uniformidad del color en las piezas moldeadas por inyección?

La consistencia del color se consigue mediante una igualación precisa del color y el uso de colorantes de calidad, junto con unas condiciones de procesado constantes en toda la tirada de producción.