Polypropylene Injection molding is a procedure in which a thermoplastic polymer is heated above its melting point and then converted into a solid polymer to a melted fluid. It certainly has a low viscosity. This melted polypropylene is then injected into molds to get the desired shape of the parts. The purpose of molding is to produce more complex forms of polypropylene products, which cannot be made if it was in their original form.

It can produce Thousands or even millions of identical parts by repeating this process if needed. Thus, polypropylene injection molding allows manufacturers to produce as many plastic parts as they want using just one mold.

Now you must be wondering about polypropylene! What actually is it? And for what is it used? Without further delay, let’s dig into the details of it.

In this article, I have discussed the main aspects of polypropylene, its benefits, and how polypropylene can be used for injection molding.

What is Polypropylene?

Polypropylene is abbreviated as PP. It is a thermoplastic in which the propylene monomers are attached to a chain through polymerization. The type of plastic polymer is recognized for its tough and flexible properties.

Importance of use of polypropylene for injection molding

PP is the best quality plastic used for injection molding. It usually exists in the form of pellets.

- Its low melt viscosity enables it to have a smooth, flowing consistency. Regardless of its semi-crystalline nature, it can be easily molded and attain any shape. This property significantly improves the degree to which you can fill a mold with the material. Thus, it remains considered the most popular material choice for manufacturing in PP injection molding.

- Its extremely slimy surface makes it an excellent replacement for other plastics in areas where less friction is required.

- Polypropylene and polyethylene have almost similar characteristics. The only difference is that PP is slightly firmer and higher temperature resistant.

- It is extremely resilient to erosion, rust, and chemical leakage. Such a property makes it perfect for storing solvents, bases, and acids.

- PP is easy to access, low-cost, and acts as a great electrical insulator.

An interesting fact about polypropylene plastic is that many manufacturers in the plastic industry call it steel. The reason is that we customize it in various ways to manufacture various products.

Here it would help if you were confused about the difference between plastic and polypropylene. Are they alike?

Think think.

A polymer with a high molecular mass is plastic. Polypropylene is an illustration of a plastic polymer. Polypropylene and plastic differ in how polypropylene may be used to create completely clear materials, whereas plastic materials are often opaque.

Uses of polypropylene injection molding

It is used to manufacture plastic parts for various products of different industries, which include:

- Packaging for consumer products such as food containers of yogurt, cream cheese, butter products, etc.

- Plastic parts for the automobile industry

- Special devices like living hinges

- Medical instruments

- Textiles materials

- Children’s toys

Steps involved in Polypropylene Injection Molding Process

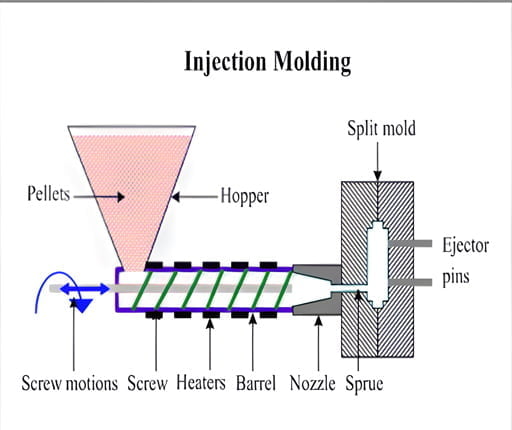

Feeding

Plastic pellets are introduced into the hopper and then tumble into the barrel.

Plasticization

The spinning screw within the barrel moves the pellet forward. The plastic pellets are warmed by the heating band encircling the barrel. The rotating screw propels the pellets forward, melting them progressively until they are completely molten when they reach the front of the barrel. Between a temperature of 450 and 500 F is the ideal range for the molding process to occur. It must melt for it to do so.

Injection

When a sufficient amount of molten plastic is present in front of the screw, the screw introduces it through the mold’s sprue and runner system into the mold cavity.

Pressure Holding

The screw will constantly force molten plastic into the mold for replacement. The molten plastic contracts inside the mold as it cools down until it fully transforms into a completely structured product. In order to keep the mold temperature within the prescribed range, the mold temperature controller injects water or oil into the cooling system.

Cooling

As the molten plastic cools down, it converts into solid form in just a few seconds.

Ejection

The ejector rod pushes forward the ejector pins as the mold unlocks. The piece and runner are dropped outside and collected in a bin. The procedure is then repeated frequently to make more plastic goods.

A rapid speed is typically used to keep internal stresses as low as possible during the Polypropylene injection molding process. However, it is preferable to utilize a slower speed at higher temperatures when surface imperfections and defects occur. The Utilization of machinery capable of providing profiled speed is highly recommended.

Gates and Runners for the Polypropylene injection molding process

A crucial step in PP injection molding is using gates and runners. The gate leading into the mold cavity is at the runner’s end. The portion has a surface imperfection caused by the gate. Because of its small size, it is intended to freeze before the part, runner, or sprue freezes. In order to prevent sink marks (recessed surfaces) during cooling, the cavity is kept packed.

Gating System for PP Injection Molding

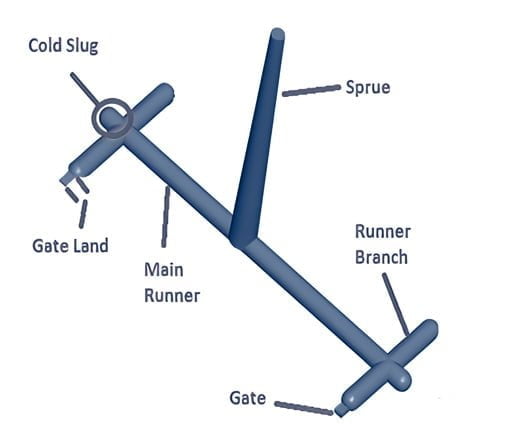

Sprue

Every Mold Has A Contact Point Connecting The Machine With A Sprue Mold. Its Hollow Spherical Base Enables The Nozzle Tip To Attach To The Molding Machine. The Nozzle Tip And The Sprue Base Need An Identical And Equal Radius. If They Do Not Attach Accurately, Then It Will Cause The Material To Leak And Produce Inconsistent Parts. Then The Melted Polypropylene Moves Through The Sprue And Arrives At The Runner.

Runner

The runner receives PP. It is a pathway that pushes the melted liquid straight into the gate of every part. In the case of only one cavity of Injection Mold, one branch is required for the runner. If it has multiple cavities, it will introduce multiple branches to guarantee a real poise of flow to get an equal proportion of material.

It is required to engineer a cold slug at every point of the branch while designing a runner. It is because there is a definite shift between each branch. When the hot melted plastic drifts via the runner system, it cools. The cold slug protects the cold polypropylene plastic from being dumped into the gate. The most often utilized sizes for cold runner molds range from 4 to 7 mm.

Gate

In the final stage, the plastic penetrates the gate. The PP injection molding process faces many gate issues at this point. Although gates can be challenging to design, learning deeply about their function can aid in producing an appropriate gate for plastic injection molded parts.

The plastic enters the gate at the end. It is where a lot of problems occur in the PP injection molding process. Gates can be complicated, but understanding their purpose can help design a proper gate for plastic injection molded parts.

The larger the gate, the better it would be to get the injection molding material in the cavity. You can employ all types of gates. The diameter of pin gates is typically set between 1 and 1.5 mm; however, they can also have diameters as small as 0.7 mm.

Gate Suitable for Plastic Injection Molding

The small size of the gate is recommended because the large landing gate will cause material degradation due to too much friction produced by heat. You can achieve smaller gates by decreasing the size of the gate land. Most companies commit that is a common mistake because the plastic immediately freezes off when it reaches the gate if the land is too big. Typically the width of land must not be more than .006″.

Positioning the Gate

The gate should be placed where the thickest wall is located. Observing the plastic moving from the gate into the cavity is crucial. It is preferable to put a gate before a standing core.

The thickest wall segment is often where the gate should be placed on any given part. It is crucial to be able to observe the plastic moving from the gate into the cavity, though. It is preferable to put a gate before a standing core on the tool.

Even though PP injection molding was invented long ago, it is the most contemporary method of producing plastic. It is done by a machine known as a polypropylene injection molding machine.

Large, industrial polypropylene injection molding machines are highly costly at over $200,000. Additional costs are associated with hiring and training trained staff, maintaining them, keeping an eye on them, and even complying with industry laws.

Since the plastic goods produced by the polypropylene injection molding process tend to be more detailed and smaller than those produced by roto molding, they naturally require more time and labor, which might raise the final cost. No worries! You can avail of the services of PP injection molding offered by Prototool.