A Comprehensive Guide To Hopper In The Injection Molding Machine

The base, barrel, hopper, and clamping unit are the four basic components of an injection molding machine. Each component plays a significant role, including the hopper in the injection molding machine. Now, if you’re unfamiliar with what a hopper is in an injection molding machine, this guide will help you thoroughly unfold it. What is […]

What is Design for Manufacturability? DFM Principles Explained

Design for Manufacturability (DFM) is a new design concept part of the Design for Excellence (DFX) mindset. DFX refers to relatively new methods for coordinating design and manufacturing processes. Because of their numerous advantages, these methodologies are increasingly used in product design. Designers select one or more DFX methods that apply to their product design […]

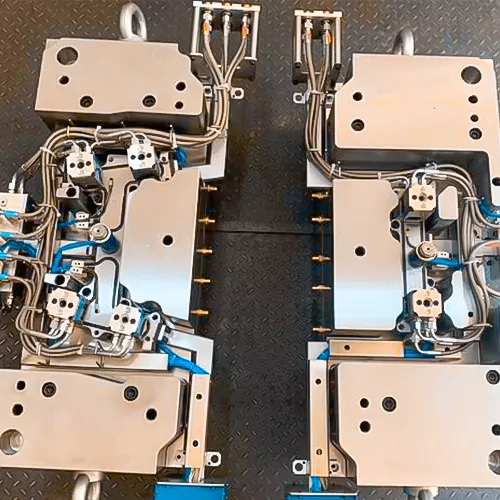

The Ultimate Guide to Designing, Making, and Maintaining The Die Casting Mold

Did You Know? Grand View Research‘s report indicates that the global die-casting market was worth $33.94 billion in 2020 and is projected to experience a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. Notably, die casting mold manufacturing finds widespread use in multiple industries, encompassing automotive, aerospace, electronics, and consumer goods, among […]

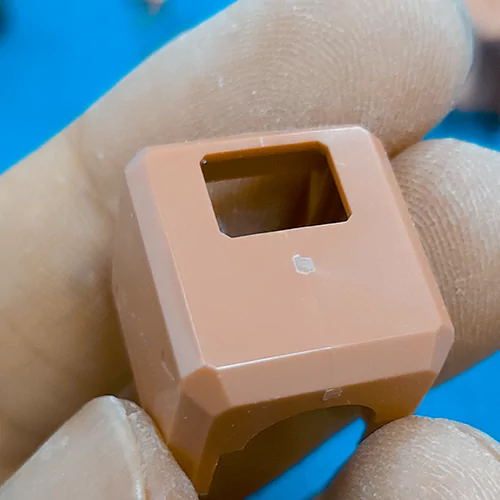

Achieving Flawless Products By Understanding Parting Line In Injection Molding: A Comprehensive Guide

If you’ve ever handled an injection molded component when manufacturing plastic products, you know that they typically have a defining line around their outer periphery. But why do you need to mold this line? How is it formed? And does it affect the quality of the plastic product or not? These can be certain concerns […]

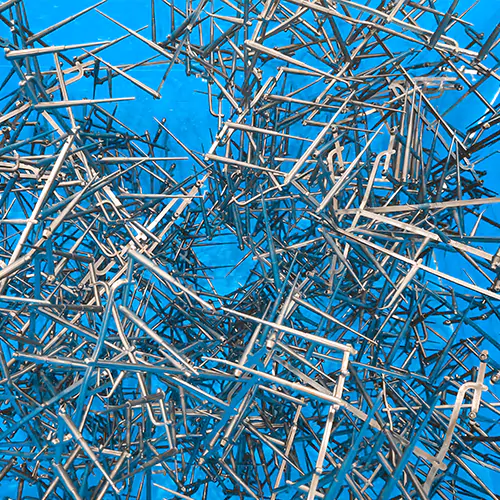

A Step-By-Step Guide on The Injection Mold Lifter Design

Designing a lifter for injection molding is a complex and technical process that requires careful consideration of many factors. A lifter is a small, movable component used to lift the molded part off the core side of the mold during ejection. It is a critical component in injection molding because it helps create complex geometries […]

Injection Molding Runner: Types and Tips for Quality Production

Undeniably, injection molding has been an integral element of the manufacturing process for many years now. People use it in various production procedures for daily objects, particularly plastic ones. Yet, few people know how this operates and the several components that need to cooperate to guarantee that the final product meets all of the necessary […]

How to design a hot runner?

Resource optimization and higher efficiency are integral parts of the molding industry. And a hot runner works as the most suitable tool to achieve both. Businesses use them to eliminate scarp plastic, providing faster cycle time and increasing. You can also achieve high quality by transferring the melt to the mold. Their hot tip and […]

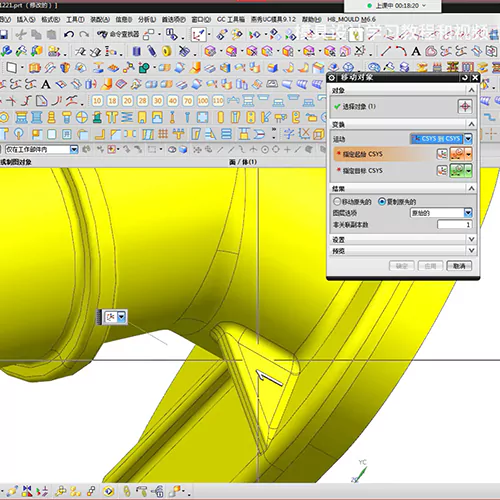

Plastic Mold Design In 2023: A Professional Step-By-Step Guide

Because the plastic mold design determines the shape of the finished product, molds are crucial to the manufacturing process.

Urethane Casting: Simple Design Considerations

Urethane casting is a popular low-volume manufacturing technique commonly used for bridge production purposes. If the term bridge production is uncommon to you, consider a production technique that serves to “bridge” the gap between early prototyping and mass production. Bridge production helps many businesses to scale up production without incurring expensive mass production expenses when […]