射出成形機のホッパーに関する総合ガイド

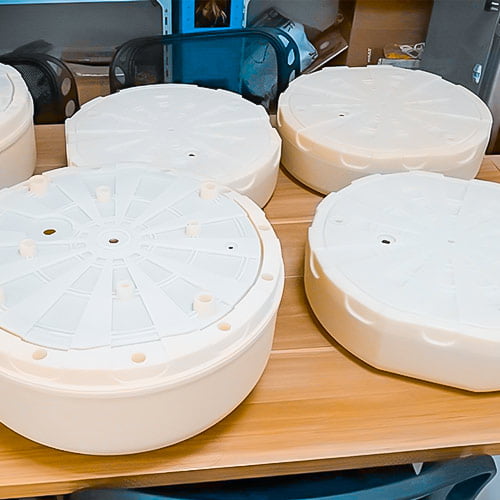

ベース、バレル、ホッパー、クランプユニットは、射出成形機の4つの基本的なコンポーネントです。射出成形機のホッパーを含め、各部品は重要な役割を果たしています。さて、射出成形機のホッパーが何なのかよく分からないという方のために、このガイドでホッパーを徹底的に紐解いてみましょう。射出成形機のホッパーとは何ですか?ホッパーは、射出成形で使用される容器または貯水池です。通常、プラスチックペレットや顆粒状の原料を、成形機に投入する前に保管するために使用されます。射出成形は、[...]に材料の一貫性のある、よく管理された供給を供給することによって達成される。

製造可能性設計とは?DFMの原則

製造可能性のための設計(DFM)は、デザイン・フォー・エクセレンス(DFX)の考え方に含まれる新しい設計コンセプトである。DFXは、設計と製造プロセスを調整するための比較的新しい手法を指します。多くの利点があるため、これらの方法論は製品設計でますます使用されるようになっています。設計者は、製品設計の目的に適合する1つまたは複数のDFX手法を選択します。そして、設計者は、それぞれの方法でコンセプトを実行することにより、優れた製品設計を実現することができます。今、あなたが製造業界の新進プロダクトデザイナーなら、DFMとその原則の使い方を理解することは、あなたのスキルを磨くのに役立つでしょう。それでは早速、DFMについて詳しくご紹介しましょう。DFMとは?[...]

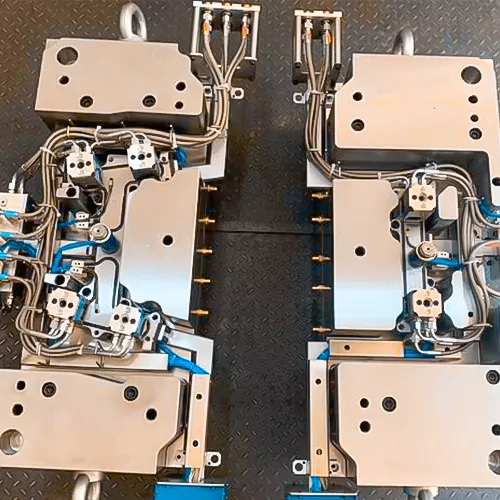

ダイカスト金型の設計、製作、メンテナンスの究極ガイド

ご存知でしたか?Grand View Researchのレポートによると、世界のダイカスト市場は2020年に$339.4億円で、2021年から2028年までの年平均成長率(CAGR)は6.2%と予測されています。ダイカスト金型製造は、自動車、航空宇宙、エレクトロニクス、消費財など、さまざまな産業で広く利用されている。この標準的な製造方法では、金属部品を正確かつ高精度に大量生産することができる。製造方法としてのダイカストの人気は、迅速なサイクル時間、形状の適応性、強度対重量の固体比、滑らかで一貫性のある表面など、数多くの利点に起因しています。この記事では、設計、製造、[...]について説明します。

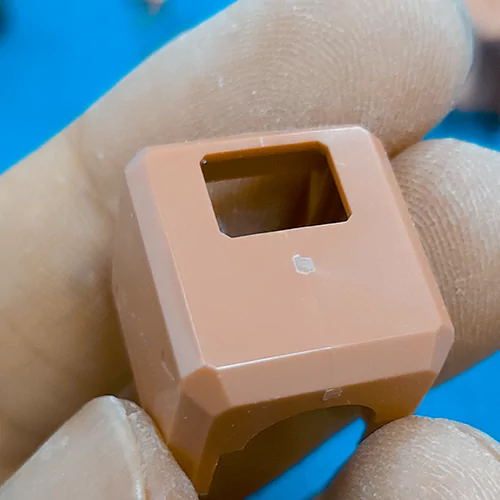

射出成形におけるパーティングラインを理解することで、完璧な製品を実現:総合ガイド

プラスチック製品を製造する際、射出成形部品を扱ったことがある人なら、通常、外周に定義線があることを知っているだろう。しかし、なぜこのラインを成形する必要があるのでしょうか?どのように成形するのでしょうか?また、その線はプラスチック製品の品質に影響するのでしょうか?これらは、パーティングラインについて調べるべき特定の懸念事項になり得ます。もしあなたがパーティングラインについてよく知らないのであれば、この記事はそれを詳しく調べるのに役立つだろう。それでは早速、詳細を見ていきましょう。射出成形におけるパーティングライン - 定義 プラスチック射出成形におけるパーティングラインとは、2つの閉じた半 [...]...

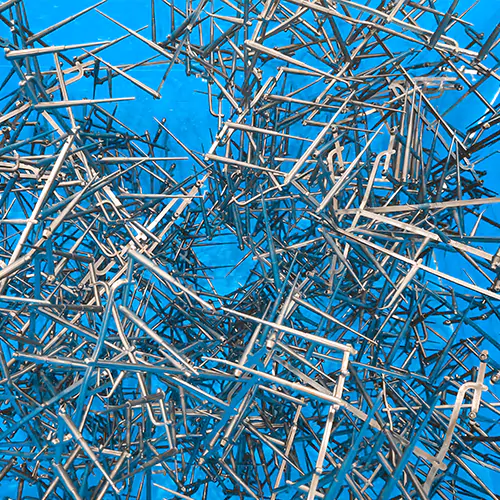

射出成形金型リフター設計のステップバイステップガイド

射出成形用のリフターの設計は、多くの要素を慎重に検討する必要がある複雑で技術的なプロセスです。リフターは、射出時に成形品を金型のコア側から持ち上げるための小型の可動部品です。成形品に複雑な形状やアンダーカットを形成するのに役立つため、射出成形では非常に重要な部品です。この記事では、エンジニアが射出成形用金型リフターの設計プロセスをどのように行うか、その詳細かつ技術的なプロセスについて説明します。詳細な9段階設計ガイド以下は、射出成形用金型リフターの詳細な設計ガイドです:ステップ1:部品の設計を分析する 射出成形用リフターの設計の最初のステップは [...] です。

射出成形ランナー:種類と高品質生産のためのヒント

射出成形は、長年にわたって製造工程に不可欠な要素であることは否定できない。射出成形は、特にプラスチック製品など、日用品を製造するさまざまな工程で利用されている。しかし、射出成形がどのように行われるのか、また最終製品が必要な基準をすべて満たすためにはどのような部品が必要なのかを知っている人は少ない。その中でも射出成形ランナーは、射出成形の設計に不可欠な部品であり、多くの部分から構成されています。もしあなたが会社や顧客のためにプラスチック製品を生産するつもりなら、射出成形ランナーについてよく知り、射出成形ランナーのさまざまな種類と、どのタイプが [...][...][...

ホットランナーを設計するには?

資源の最適化と効率の向上は成形業界にとって不可欠な要素です。ホットランナーは、その両方を達成するための最適なツールとして機能します。企業はホットランナーを使用することで、プラスチックの削れをなくし、サイクルタイムを短縮し、生産性を向上させることができます。また、溶融物を金型に移送することで、高品質を実現することもできます。そのホットチップとバルブゲートの構成は、システムがそのプロセッサソリューションを構築するためのカスタマイズ可能なアプローチを得ることを保証します。その結果、成形システムはより高い効率を提供します。しかし、ホットランナーの設計は、その潜在的な利用可能性を完全に決定する上で重要な役割を果たします。従って、ホットランナーの設計プロセスと構造を理解することは[...]重要です。

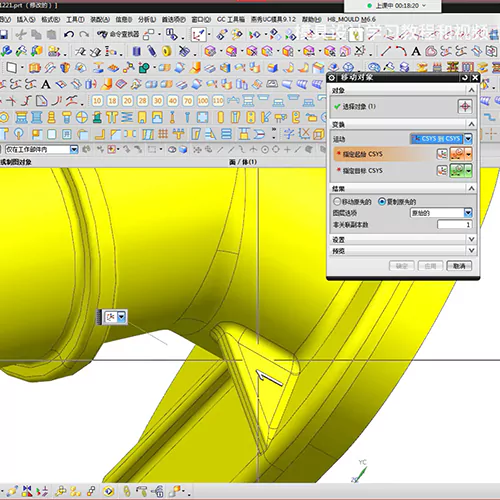

2023年のプラスチック金型設計:プロのステップバイステップガイド

プラスチック金型の設計は完成品の形状を決定するため、金型は製造工程で非常に重要である。

ウレタン鋳造:簡単な設計上の注意点

ウレタン鋳造は、ブリッジの生産によく使われる少量生産技術です。ブリッジ生産という言葉が聞き慣れない場合は、初期の試作品と大量生産の間の「橋渡し」をする生産技術を考えてみてください。ブリッジ生産は、多くの企業にとって、試作品のレベルにとどまることができない場合に、高価な量産費用を負担することなく生産を拡大するのに役立ちます。ウレタン鋳造は、マーケティング、ビジネス・ピッチ、あるいは社内のアイデア・テストに役立つそっくりなモデルを作る最も効率的な方法のひとつです。ウレタン鋳造では、複雑な形状の部品を少量生産することができ、すぐに使用することができます。一般的に、ウレタン鋳造は [...] 続きを読む