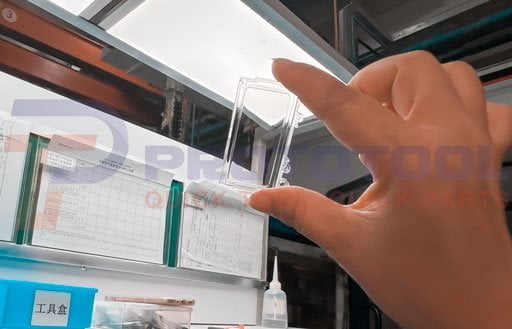

Suppose you ever happen to visit a clear injection molded plastics factory. In that case, you will notice that clear plastic injection molding involves melting a raw material, pushing the viscous fluid into a injection mold, and allowing it to cool and harden.

Almost every product, from electronics to home goods to automobiles to food packaging, uses molded components. Even though it appears to be a relatively easy operation, there is a lot of science involved in performing it correctly, from making the molds to comprehending the chemical and physical characteristics of the materials.

In this guide, you will learn everything about clear injection molded plastics. It also includes the technology’s fundamentals, materials, characteristics, and helpful design advice.

Let’s start.

Introduction To Clear Plastic Injection Molding

Clear plastic injection molding is a manufacturing technique that enables the mass production of components through injection molding. The process involves pumping molten materials into a mold, which is usually used in mass manufacturing to create thousands of similar goods. Metals, glassware, elastomers, and sweets may all be molded by injection molding.

Characteristics of raw materials used in clear plastic injection molding

● Material Flexibility

A material’s flexibility and softness are frequently misinterpreted. The capacity of a product to resist bending under intense pressure is referred to as stiffness. The material’s capacity to mold and bend under pressure without tearing or wasting determines its flexibility.

For instance, ABS is a strong plastic that is yet quite flexible. Before it starts to shatter, it may bend to a significant extent. When under strain, nylon polymer quickly breaks.

● Material Weight

The attribute of material weight affects the final product’s weight and density. For instance, polyethylene is the best material if you need something light, and nylon is a rigid injection molding material to tackle if you require a hefty substance.

● Material Cost

Material cost is undoubtedly crucial when making china clear injection molded plastics. However, it’s crucial to base material choices more on the product’s use than just on price.

● Chemical Resistance

Every clear injection molded plastics manufacturer looks for great chemical resistance quality for a product that can operate in various environmental circumstances. The best materials for this purpose include nylon, polycarbonate, and acrylic, and these substances must be impervious to moisture, acids, and alkalis.

Problems That May Occur During The Clear injection Molding Process

While making clear injection molded plastics, we should consider the following problems to avoid bad backflow or uneven cooling, which may cause poor plastic molding, surface flaws, and overall molding design degradation.

- Transitions should be gradual and seamless to avoid sharp edges. PC goods, in particular, must not have gaps due to the production of sharp edges.

- The draft angle should be sufficient, and the wall thickness should be as uniform as feasible.

- The mold’s surface should be free of ridges and have a roughness of no more than 0.8.

- You should adjust the gate location following the shrinkage condensation process, and the flow route should be as broad and thick as feasible.

- Wall thickness should typically not be less than 1mm, except for pets.

- The tank must have a large vent opening that is enough to release air and gas while melting.

Factors To Consider To Minimize Internal Stress And Surface Quality Flaws

- Given the assumption that plastic resin does not disintegrate, the injection temperature should be high.

- Utilizing a special screw and injection molding machine with a separate temperature control nozzle is recommended.

- Injection pressure is typically strong to overcome the melt’s high viscosity defect, but it will produce internal stress if it is too high, leading to poor de-molding and deformation.

- Injection speed: It is often slow while filling a mold. Using a slow, rapid, and slow multi-stage injection is preferable.

- Screw speed and back pressure should be as low as feasible to meet plasticizing quality and avoid the probability of depreciation.

- Cooling significantly impacts the final product’s quality. As a result, mold temperature must be precise in controlling the operation, and the mold temperature should be as high as possible.

- If the product filling is satisfactory, there are no dents or bubbles, and it should be as brief as possible to reduce the time the melt remains in the barrel.

Common Raw Materials Used to make clear injection molded plastics

Contrary to unclear injection molding, clear plastic injection molding requires more concentrated attention to detail and stringent manufacturing controls. Knowing which transparent plastic would suit your demands the best is crucial for this reason.

Here is the list of clear injection molded plastics suppliers’ recommended best common raw materials used to make clear injection molded plastics.

Acrylic

One of the most popular polymers used in outdoor equipment is acrylic. It is also highly sought after in products like light fixtures, retail displays, reflectors, and colored lenses because of its capacity to equally distribute additive applications such as colorants throughout the part during the injection molding process.

Nylon (PA)

A variety of nylon quick-release buckles are made of nylon (PA). Another nylon name is PA, and its chemical symbol (Polyamide). This is intended to demonstrate the robustness and adaptability of nylon resin. Strong mechanical components like bushings, gears, and bearings are frequently made from nylon. It is widely used in automotive applications because, in addition to being durable, it contributes to weight reduction and cheaper production costs compared to a metal equivalent.

Polycarbonate

Polycarbonate is more costly than the other two polymers and is an impact-resistant substitute. It is stronger and far less sensitive to high temperatures than acrylic. Yet, it has the same transparency and UV protection. Safety goggles, helmets, shields, heavy-duty containers, and safety windows are just a few examples of items made from this plastic intended to withstand stress.

Polyethylene

High heat and pressure turn petroleum into the thermoplastic known as high-density polyethylene (HDPE). Similar to acrylic, it is UV resistant and versatile, with the added benefit of being simple to form. These features, paired with their inexpensive nature, are why it’s used in the mass production of popular items such as bottles, pipes, and containers.

Thermoplastic Rubber (TPR)

a picture of a TPR rubber-made medical catheter. Thermoplastic Rubber (TPR) resin, which is simple to use in the injection molding process, is a blend of plastic and rubber. TPR is employed in various fluid dispensers, flexible hoses, catheters, and other locations holding various liquids, including acid.

Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) has excellent tensile and tear strength while being soft and elastic. TPU makes it easier for objects that need to be grasped firmly in hand to grip. However, you should know that TPU is more expensive than other resins. Because of this, it’s frequently utilized to create components that require rubber, such as elasticity.

Polypropylene

Polypropylene, sometimes referred to as PP, is frequently utilized in textiles, packaging, and containers. The textile sector is frequently used in products like waterproof bags, totes, and gear. Due to its great flexibility, it is perfect for living hinge applications and other non-load-bearing elements. Due to its high electrical resistance, it is also utilized in electronics.

Polyetherimide

A typical plastic used in mechanical, chemical, and industrial parts is polyetherimide (PEI). Its use may be seen in temperature sensors, heat shields, aircraft engine parts, and various electrical equipment and coverings. Due to its resistance to high temperatures and repeated stresses, this transparent material is frequently used in the automotive, electrical, and medical industries.

Defects and solutions of clear plastic parts

This part of the guide will cover defects impacting product transparency and their solutions. The most likely defects are as follows.

Bubbles

When the resin is condensed in a mold, water vapor and other gases are not released, or the condensation surface condenses too quickly, owing to inadequate filling, creating a vacuum bubble.

Silver streak

Internal stress anisotropy is impacted by the filling and condensing process. The stress in the vertical direction forces resin to be orientated on flow, whereas non-flow orientation results in a variable refractive index and creates a flashing silk pattern. Its expansion might result in product fractures.

Seismic pattern

refers to a thick groove formed from the core of the sprue. The front-end material has been condensed in a cavity due to excessive melt viscosity. When the material is broken through the condensation surface, it appears as a seismic pattern on the surface.

Poor surface gloss

Because of the high mold surface roughness and the premature condensation that results from it, the surface of the cattle is somewhat uneven, and the product is tarnished.

White smoke/Black spot

The primary reason it forms is that when plastic is within a barrel, the resin degrades or breaks down due to localized overheating.

Whitening/Haze

Haze is mainly brought on by raw material with excessive moisture or dust dropping into it from the air.

Conclusion

The simplest method for producing several similar objects in bulk from unprocessed plastic polymers is plastic injection molding. When we consider what it does, it is a cost-effective strategy. The advantages of plastic injection molding are widely promoted. It’s perfect for the reliable, cheap manufacture of a variety of challenging, sophisticated plastic parts. We have covered everything you need to know about injection molding in this article, but there is still much to learn.