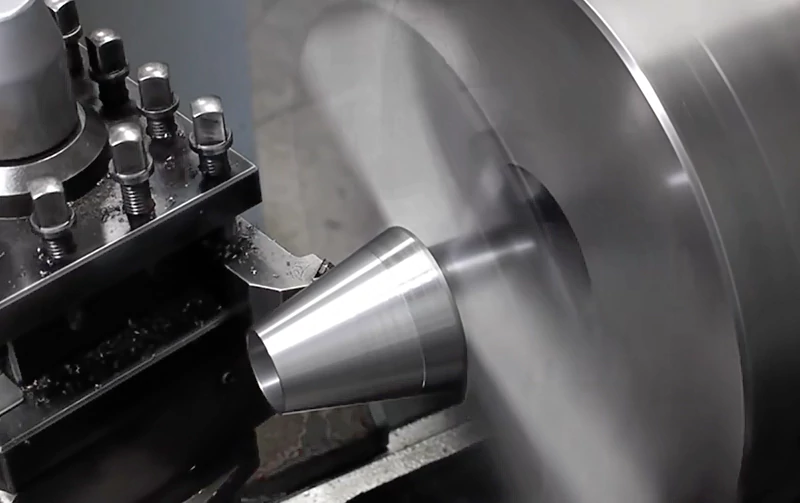

A fundamental operation conducted on a lathe, taper turning is a craft that orchestrates a subtle dance of dimensions along the length of a cylindrical workpiece.

In this intricate process, the once uniform diameter gracefully transforms into a tapered shape, unveiling a meticulous creation where one end boasts a grander diameter than its counterpart.

At its core, taper turning is a tale of angles, where the cutting tool’s journey takes center stage. The angle adjustment becomes the maestro’s baton, dictating the symphony of taper rates.

A steeper angle commands a swift metamorphosis in diameter, while a gentler angle choreographs a more gradual transformation. To help you better understand, this article will explore taper turning techniques and lathe operations in depth. Keep reading to learn all about it!

How Taper Turning Works on a Lathe Machine

The lathe machine, often called the backbone of machining, has evolved significantly, leading to advanced CNC turning centers that boast exceptional precision and accuracy. Despite the rise of modern CNC machines, the conventional lathe machine remains widely used, valued for its cost-effectiveness in machine shops worldwide.

Importance of Taper Turning

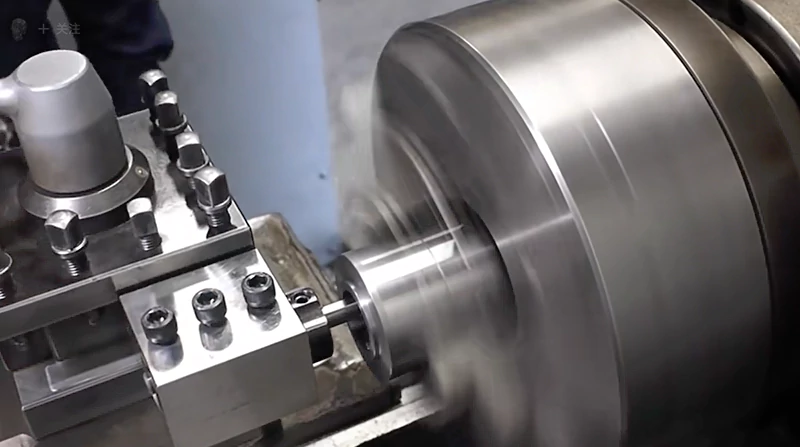

Taper turning, a fundamental operation on a lathe, holds immense importance in manufacturing. Tapers are crucial in creating tight and precise fits, especially when joining two components.

Manufacturers recognize the significance of accurate taper turning, making it a staple in various production processes.

Evolution of Lathe Machines

The evolution of lathe machines has paved the way for seamless taper turning, even in CNC turning machines. Incorporating taper turning into a lathe, whether traditional or CNC, offers a user-friendly experience for lathe makers and turners alike.

Key Variables in CNC Taper Turning

It involves grasping essential variables in the process. Cutter orientation, feed rate, depth of cut, and cutting speed are the primary elements that come into play.

These variables collectively determine the precision and success of the operations on a CNC lathe.

The CNC Taper Turning Formula

The core of calculations revolves around the taper angle (alpha).

When dealing with Taper Per Foot (TPF), you must use the formula:

Alpha = arctan(TPF/12).

The subsequent step delves into calculating the radius (r) at each point along the taper’s length. The radius at any point “x” in the taper’s journey is determined by:

r = r0 – (x TPF).

Here, `r0′ represents the initial radius, and ‘x’ signifies the distance traveled along the taper’s length.

The calculation incorporates the relationship for CNC machines with incremental values:

x = r0/F (Feedrate).

This expression serves as a general guideline, shedding light on the machine’s behavior under diverse working conditions. Understanding these calculations empowers machinists to navigate the intricacies of CNC taper turning with precision and confidence.

Types of Taper Turning Methods

1. Tailstock Set-Over Method

Applicability

The Tailstock Set-Over Method is a specialized technique suited for crafting small top angles, providing a meticulous solution for the precision machining of tapered profiles. Machinists often use this method when dealing with intricate components that demand accuracy.

Limitation

Despite its precision, this method is confined to external tapers only, making it suitable for scenarios where only the outer surface needs tapering. This limitation underscores the importance of choosing the right method for the specific machining requirements.

Procedure

- Alignment Adjustment: Initiate the process by carefully adjusting the tailstock from its regular position. This step ensures that the tailstock is set in a way that aligns with the taper requirements.

- Offset Calculation: Precision is maintained by calculating the offset using the formula O = (Taper × L)/2000. This calculation is crucial for achieving the desired taper with accuracy.

- External taper Turning: Execute the external taper turning with the clamping mechanism loosened for offsetting. This controlled approach ensures that the final product meets the specified taper requirements.

- Machinist Tips: Mastery of this method unlocks external taper precision and facilitates a power feed for efficient machining. Machinists can leverage this feature to achieve a smooth and controlled taper-turning process.

2. Compound Rest Method

Applicability

The Compound Rest Method emerges as a versatile technique suitable for crafting small and steep tapers, showcasing machining excellence across various applications. Machinists often turn to this method when faced with creating diverse taper profiles.

Procedure

- Compound Rest Setup: Set the compound rest at a specific angle, aligning it precisely with the center line of the workpiece. This step establishes the foundation for accurate taper turning.

- Tool Alignment: Lock the compound rest into position, ensuring the cutting tool is precisely aligned at the center for optimal results. This meticulous alignment is critical for achieving the desired taper.

- Taper Turning: Achieve taper turning by manually turning the handle of the compound rest. This hands-on approach allows machinists to maintain control and precision throughout turning.

- Turning Techniques: This method turns both internal and external tapers, with the compound rest angle calculated by Tan θ = (D-d)/(2L). This calculation emphasizes the importance of precision in turning techniques.

3. Taper Turning Attachment Method

Applicability

The Taper Turning Attachment stands as a precision tool designed for modern lathes, ensuring machining precision in diverse lathe operations. Machinists leverage this attachment to handle a variety of taper-turning scenarios with efficiency.

Procedure

- Attachment Setup: Mount the attachment behind the carriage, showcasing its adaptability and relevance in modern lathe operations. This setup allows for seamless integration with the lathe.

- Workpiece Holding: Hold the workpiece between centers or in a chuck while the attachment facilitates taper turning without tailstock offsetting. This flexibility in workpiece holding enhances the attachment’s usability.

- Swiveling Guide Bar: Swivel the guide bar at a 10° angle, showcasing the attachment’s ability to handle varying taper angles easily. Machinists can adjust the guide bar to accommodate different taper requirements.

- Taper Turning Mastery: Professionals can achieve both external and internal tapers with this attachment, maintaining the alignment of lathe centers. The Taper Turning Attachment becomes a masterful tool in the machinist’s repertoire.

4. Form Tool Method

Applicability

The Form Tool Method, with its straight form tool, is a technique meticulously designed for short-length tapers, offering precision in turning methodologies. Machinists often employ this method for components that demand short, well-defined tapers.

Procedure

- Form Tool Setup: Set a straight form tool with a taper angle for the desired form on the workpiece, emphasizing the need for accuracy. Machinists must carefully choose the form tool to match the taper requirements.

- Direct Feed Operation: Provide a direct feed on the job to ensure the creation of a definite form. This direct feed operation requires a controlled approach to prevent errors in the taper profile.

- Consideration for Length: Due to the limitations of this method, it is recommended for short-length tapers, underlining the importance of understanding its scope. Length considerations play a crucial role in the success of the taper-turning operation.

- Precision Machining: While effective, machinists must consider that more force is not generated, making it suitable for specific machining scenarios where short-length precision is paramount.

5. Combining Feeds Method

Applicability

The Combining Feeds Method is an advanced turning technique that engages both longitudinal and cross feeds for diagonal tool movement and showcases a high level of machining precision. Machinists use this method when aiming for intricate taper profiles with advanced turning requirements.

Procedure

- Simultaneous Feed Engagement: Engage longitudinal and cross feeds simultaneously, allowing the tool to travel along a diagonal path. This simultaneous engagement adds a layer of complexity suitable for advanced scenarios.

- Trajectory Adjustment: Adjust feed rates and gears to optimize the trajectory of the tool, underlining the need for meticulous adjustments for precision machining. Machinists must carefully calibrate feed rates to achieve the desired taper.

- Turning Methodologies: This advanced method showcases the potential of combining feeds for diagonal tool movement, emphasizing the importance of feed rate adjustments in achieving precision in turning methodologies. Machinists must employ advanced turning methodologies to master this technique.

Conclusion

Mastery over CNC taper turning calculations becomes a key to unlocking efficiencies and the production of intricate, high-quality parts tailored for diverse industries. The intricacies of this process underscore the pivotal role of accurate calculations in achieving desired outcomes, making it imperative for manufacturers to grasp these calculations.

In conclusion, while CNC taper turning might seem intricate, a profound understanding and hands-on practice can improve efficiency and heightened precision in your machining endeavors. As manufacturing continues to advance, precision is still a top priority. It is a clear example of the industry’s dedication to high-quality machining.

At Prototool, we stand ready as your reliable partner in CNC manufacturing services. Our commitment to precision machining and advanced turning techniques positions us as masters in the craft. Hence, we’re always here to guide you through the efficient process of taper turning to achieve machining excellence. Happy Machining!