Injection molding is primarily a phenomenon in the manufacturing processes of plastic. It is a manufacturing process that involves shaping a liquid or malleable raw material with the help of a fixed frame, also known as a mold or a matrix. A mold is a hollow cavity receptacle, usually made of metal, into which liquid plastic, metal, ceramic, or glass is poured. Other mold parts are used for the manufacturing processes of plastics.

Different Kinds of Molding Processes

Plastic is a synthetic substance that can be molded into any shape using a variety of molding techniques. Different mold components are used during these molding procedures. Both procedures entail working with molten plastic before letting it cool. Thermoplastics, unlike thermoset plastics, can be melted and molded if necessary. The manufacturing of plastic is facilitated through the use of various molding processes. These molding processes are listed below.

Casting-

This is one of the most straightforward processes out of all molding processes. The process uses only a few mold parts and is cost-efficient as well. Plastic is heated until it becomes fluid and then poured into the mold. It is allowed to cool before the mould is removed. This process is suitable for intricate shapes and can be carried out under low pressure.

Extrusion Molding-

The process facilitates molding the plastic or metals in a pre-defined shape and form. The plastic is melted and pushed through a die to create a linear structure. The die is one of the unique mold parts used for extrusion molding. The final shape commonly referred to as a rod but not necessarily cylindrical, is cooled and can be cut to various lengths depending on the application.

Compression Molding-

The process of compression molding involves using the raw liquid form of plastic and its compression in a mold to form the desired shape of the part. The benefit of the high temperature being used during the process is the added strength of the metal. The product is cooled for some time before removing it from the mold. The process is mainly used in the automotive industries, where small parts are required in high numbers.

Blow Molding-

The machine heats the raw plastic until it becomes liquid, then inflates it like a balloon with air. The plastic is blown into a shaped mold, pressed against the walls, and begins to take shape. The liquid balloon is cooled after filling to keep its form. The process is swift, with the ability to produce up to 1400 pieces in a 12-hour workday. The advantage of the process is that through the standard technique, a plastic part quickly obtains a uniform wall thickness. Blow molding requires different mold parts for its entire process than other molding processes.

Rotational Molding-

This method involves placing the hot liquid metal inside the mold and then rotating it at high speeds. The liquid then evenly coats the entire surface, resulting in a hollowed part with uniformly thick walls. After the mold has cooled and the liquid plastic has taken its new shape, it is removed from the mold. The advantage of this process is that raw material rarely goes to waste. Hence, it is an environmentally efficient process.

Injection Molding-

The most important and commonly used manufacturing process for producing plastic or metal parts is Injection Molding. The process is similar to extrusion molding. The liquid metal is directly inserted or injected into the pre-existing custom mold during this process. The injection’s high pressure facilitates the mold’s filling and solidification.

This is a standard method for producing large quantities of plastic parts, such as car or surgical parts. It is commonly adapted when the parts required annually are above 30,000. Products can also be manufactured with greater flexibility to meet the specific requirements of designers or engineers. Despite the process being used for expensive metals, the process proves to be cost-effective considering the production volume.

How does injection Molding work?

Regarding these manufacturing processes, injection molding is the most commonly used. It is preferred the most because it contributes to producing highly identical plastic parts. The method also facilitates design flexibility. Injection molding is used to manufacture most parts, from car parts to electronic enclosures and kitchen appliances. However, injection molding has comparatively high start-up costs compared to other technologies, primarily due to customized tooling requirements. Depending on its complexity, accuracy, and material (steel or aluminum), the financial cost of the whole process varies.

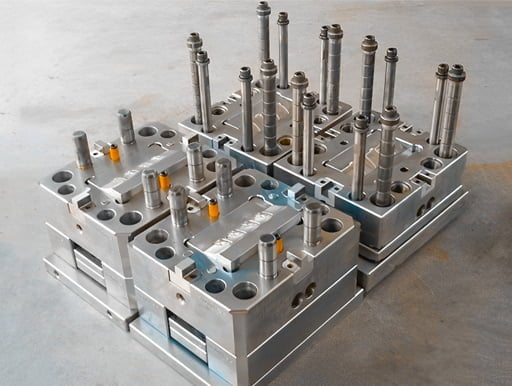

An injection molding machine consists of three main parts: the injection, the mold, and the clamping unit. These are all parts essential for the molding process.

Injection Unit

The injection unit facilitates the melting of the raw plastic and guides it into the mold. It comprises smaller and more fundamental mold parts such as the hopper, the barrel, and the reciprocating screw. The polymer granules are mixed with the coloring pigment or other reinforcing additives in the hopper after being dried and deposited in the injection unit. The material is heated, mixed, and moved in the direction of the mold as the granules are supplied into the barrel by a variable-pitch screw. The barrel and screw geometry have been carefully chosen to help increase the pressure to the required levels and melt the material.

As the ram moves forward, the melted plastic will be injected into the mold via the runner system, filling the void. The substance reconsolidates and adopts the shape of the mold as it cools. The mold finally opens, forcing the solidified item out by the ejector pins. After that, the mold shuts, and the procedure is repeated. All the mold parts have a core role in the manufacturing part of the plastic parts from the polymer granules.

Manufacturing Of The Mold

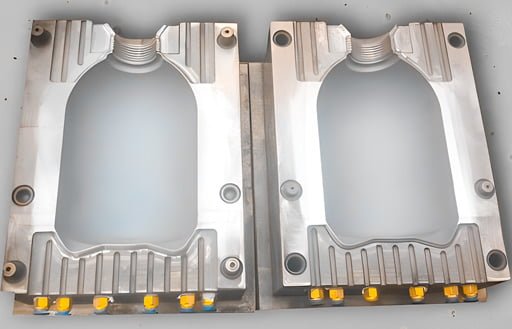

The mold is one of the parts used in manufacturing the parts that form the majority of the upfront cost of the whole process. A mold is a hollow metal block into which the molten and processed plastic is injected to form a custom fixed shape. The geometrical shape and dimensions of the mold are transferred into the injected part. Due to the high price of the mold, there are now variations of the mold with flexible features and designs. However, the simplest of this mold is the straight-pull model.

The anatomy of the straight-pull model is discussed. It has several mold parts that facilitate the manufacturing process. The mold consists of 2 halves: the cavity and the core. Injection molded parts have two sides. The A side of an injection-molded object faces the cavity, and the B side faces the core (back half of the mold). The A-side, or the cosmetic side, typically has a better outward look. According to your design requirements, the faces on the A side will either be smooth or textured.

On the other hand, the part’s concealed but crucial structural components are typically found on the B side. It is referred to as the functional side for this reason. The B side frequently has a rougher surface and obvious ejector pin markings.

The Runner System

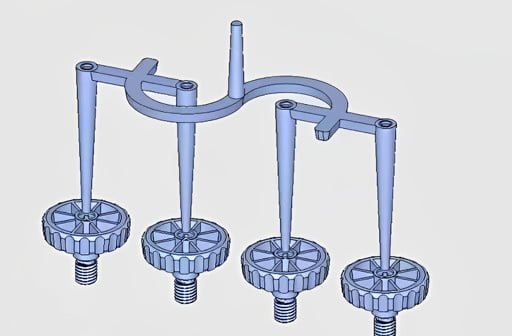

The mold parts have a crucial role in injecting the liquid material into the mold for the final procedure. The channel that guides this liquid material into the mold is called the runner system. The runner system usually regulates the flow and the pressure with which the liquid is injected into the mold. This runner system further consists of three sectional parts or mold parts.

- The sprue is known as the main passageway down which the melted plastic initially flows when it enters the mold.

- The runner joins the spur to the gates by spreading the molten plastic along the face where the two sides of the mold converge. The substance may be directed toward one or more portions by one or more runners. After ejection, the runner system is disconnected from the component.

- The gate (is the point at which material enters the cavity. Its geometry and position are crucial because they affect the plastic flow.

These gates are also available alternatively for different applications. The different kinds of gates are listed below.

- Edge gates- The most common gate is an edge gate, which injects material when the two parts of the mold split.

- Tunnel gates inject material just below the parting line. To completely eradicate the requirement for manual removal, the runner system snaps off when the part is expelled from the mold. Because of this, this kind of gate is perfect for high volumes.

- Post gates infuse the substance from the cavity’s backside, concealing the minor flaw that remains after breaking the other gate kinds. These gates are utilized for components that need to look fantastic.

- Hot tips- Directly attached to the spur, hot tips inject plastic into the part’s upper side. In this way, none of the material goes to waste.

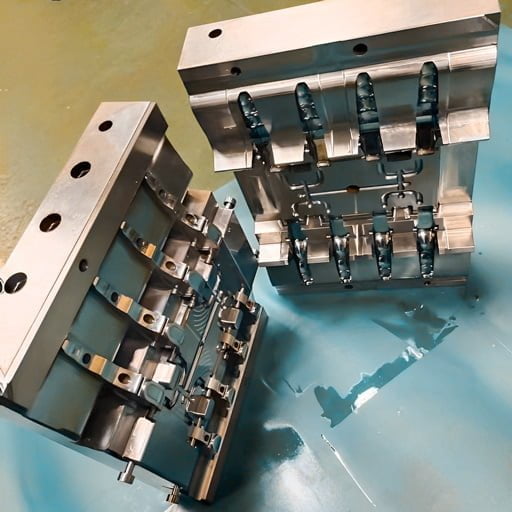

Clamping System

The clamping system is on the opposite side of an injection molding machine. The clamping mechanism serves two purposes: it forces the part out of the mold after it opens and tightly seals the two parts of the mold during the injection.

These parts form this whole system that facilitates the manufacturing process. The mold parts are efficiently structured in the way that the injection molding is made possible. The molding is further used to produce high volumes of individual plastic or metal parts that are used in different industries.

Conclusion

Molding typically occurs during the plastics production process. A fixed frame sometimes referred to as a mold or a matrix, is used in the manufacturing process of molding to shape a liquid or pliable raw material. There are different types of molding processes, such as casting, extrusion, compression, etc., which together make the complete molding chain.