Being a fabrication process, die cutting uses specialized equipment and machine tools to cut, mold, and shear stock material into unique forms and designs. The die-cutting method is versatile and adaptable to various materials, including metal, plastic, wood, and composites. It is also used in various sectors for die-cutting neoprene, gasketing, paper, packing, die-cutting cloth, and generating die-cut foam. Today, numerous die-cutting processes are accessible, including flatbed, rotary, and digital die-cutting. However, regardless of the process, specific processing equipment must always be used following the processing requirements and die tooling procedure you select.

This guide provides all the insights you need on die tooling for the unfamiliar. So, without further ado, let’s dive into the details.

Types of Tools Used to Process Die Tooling:

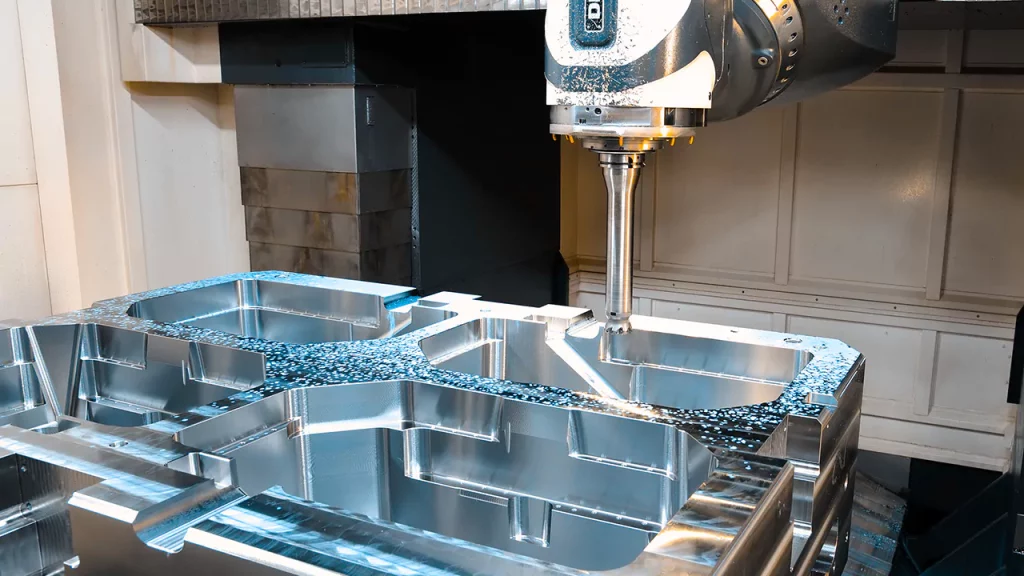

1. CNC Machine:

A CNC machine precisely manages a metal workpiece’s cutting, drilling, grinding, and other machining operations using specified software and hardware. Metal CNC machining, metal shaping and milling, hole-making, and other metal processes are performed on this equipment.

Types of CNC Machines:

Different types of CNC machines can be used depending on the usage and type of product being processed during the die tooling procedure. Some of the common types and features of CNC machines that are often used during this process are:

- Vertical CNC machine

- Horizontal CNC machine

- Engraving CNC machine

- Milling CNC machine

Varying on the machine you use during die-tooling, you can acquire high-speed or multi-axis machining centers to further process the material through other tools.

2. Gun Drilling:

Gun drilling is a deep hole drilling technique that produces holes in metal with high depth-to-diameter ratios by using a long, thin cutting instrument. It works well in sizes ranging from 1 to 50. The distinctive head shape of a gun drill tool distinguishes it from a normal twist drill; a standard gun drill has a single effective cutting edge that removes chips as it advances into a metal workpiece.

Using high-pressure coolant for clean chip exhaust even at extreme depths in the gun drilling method can drill deeper holes than conventional machinery and gear such as twist drills.

Gun Drilling Characteristics and Usage:

- The gun drilling procedure is used to create deep, straight holes. When compared to traditional twist drilling, this procedure is more specialized.

- The conventional geometry of a gun drill tool features a single effective cutting edge. Unlike the twist drill, the gun drill cuts through the metal eccentrically and self-pilots once inside the component. The guiding pads further burnish the hole, resulting in a precise round hole with sustained straightness. The coolant enters the tool via the coolant hole, and the chips exit by the V-shaped profile on the gun drill.

3. EDM Machine:

Electrical Discharge Machining, also known as EDM, is a metal removal process that removes less material than traditional machining but produces a more accurate and finer surface finish.

Metal is removed from a workpiece using EDM by passing an electrical current from one electrode to an oppositely charged electrode implanted into the workpiece. After that, the metal is evaporated or melted away.

EDM Machine Types and Usage:

EDM machine with die sinker or ram

This type of EDM machine generates cavities in a workpiece, which is important in producing tools and dies, metal stamping dies, and various plastic molds, among other things.

- EDM Hole Drilling Machine

Hole drilling EDM is used to machine holes, as the name suggests. However, as compared to typical hole drilling procedures, this approach can accurately create extremely small and deep holes that do not require deburring.

- EDM machine for wire

A wire EDM machine operates like a cheese cutter or a bandsaw cuts wood, except that the wire moves rather than the workpiece. High-voltage electrical discharges are carried via a metallic wire (typically brass or copper), allowing it to cut through the whole thickness of the material. Cutting will take place from the edge, or a hole will be bored in the item to allow the wire to pass through if pieces need to be cut out from the inside.

4. Surface Grinder:

The surface grinding machine is the most frequent form of grinding machine found in any shop. It is similar to a milling cutter with many teeth, but the surface grinding machine has a grinding wheel, making it an abrasive cutting tool. The wheel removes extremely minute metal fragments (known as swarf). It operates due to the wheel’s thousands of cutting edges.

These surface grinding tables are utilized for a variety of tasks, including the removal of excessive material. They perform extremely well on hard materials (such as steel and diamonds) to achieve a high-quality final surface.

Surface Grinding Machine Characteristics and Usage:

Once the table has raised the piece somewhat further into the wheel, the chuck on the surface grinding machine rotates back and forth. Using this machine, you can set intervals (e.g., 0.001 inches / 0.0254 mm) with each pass.

Small portions of the object’s substance are removed each time the grinding wheel revolves with its abrasive particles to create a smooth surface.

As a result, the surface grinding process is typically used as a finishing step to get an object to a specific tolerance. Still, it is frequently followed by a polishing technique during the grinding-and-lapping process.

5. Milling Machine:

A milling machine is equipment that rotates a circular tool with several symmetrically aligned cutting blades along its axis, and the workpiece is often held in a vise or similar device secured to a table that may move in three perpendicular directions.

Milling machines often machine irregular and flat surfaces in solid materials such as metal, plastic, and wood. In contrast to a lathe, where the workpiece rotates during the cutting operation, the cutter is designed to rotate.

Milling machines are powered machine tools used to cut or carve material. Mills employ various cutting instruments, such as revolving blades, drills, and even abrasives.

Milling Machine Characteristics and Usage:

- The greatest mills have high-quality cast iron structures, variable speed engines, power feeds, and cutting tools that move along the x- and y-axes. Milling machines are used in various applications, from woodworking to metallurgy.

- Self-contained electric drive motors, coolant systems, digital readouts, variable spindle speeds, and power-operated table feeds are common features of milling machines. They can also drill, bore, cut gears, and create slots and pockets.

- A milling machine is designed to securely hold material in a vise or otherwise secure to the mill’s bed. The cutting tool commonly moves horizontally or vertically, giving rise to the two basic types of milling machines: horizontal and vertical.

- Vertical mills employ a spinning cutting tool similar to a drilling machine or drill press. The drill chuck is lowered into the workpiece after being positioned on a gantry above the mill’s bed.

- A single-pointed milling cutter is commonly used as a cutting tool. Milling machines have tool heads that spin at speeds ranging from 500 to 50,000 RPM, depending on the model.

- A horizontal milling machine works the same way as a vertical mill, except it has a rotating table instead of a gantry, and its main cutter is usually three or four points. The cutting speed of these mills varies according to specifications, although it can reach 20,000 RPM.

6. Die Spotting Press Machine:

A die-spotting hydraulic press machine is a type of hydraulic press designed to improve mold (die) precision and placement capabilities. It is commonly used for mold assembly, adjustment, inspection, and maintenance, including low-pressure injection molds. It verifies dimensional accuracy by checking the mold’s contact surface and its components.

The hydraulic die spotting press is one of the most dependable and safe machines for inspecting the butt joint of the mold core and cavity. Matching mold elements and verifying mold creation becomes easier and more ergonomic. The basic die spotting press model enables convenient loading, unloading, and customization to meet customer requirements with its spacious table and open height. Metal, plastic, and other synthetic materials can make molds. Different material qualities necessitate various inspection and testing methods.

Die Spotting Press Characteristics and Usage:

- To meet the needs of various industries, the die spotting press can be equipped with an inclined platen, rolling pad, 180-degree rotating platen, automatic clamping and lifting packaging, servo-controlled slider parallelism control system, information request, and other devices.

- Die spotting presses are used for various purposes, the most common of which are mold placing, finishing, and inspection. It plays a key role in the metal forming and plastics industries.

- Due to their versatility, these machines are found in various industries, including household appliances, automobiles, and aerospace.

7. Turning Machine:

A turning machine is a machine that molds workpieces into different shapes. A part is rotated while a single-point cutting tool moves parallel to the axis of rotation. The technique can be carried out on the workpiece’s external or internal surface. Most of the time, the beginning material is a workpiece generated by another process. Some portions, however, may necessitate further operations like polishing or platonic solids.

Turning activities are often performed by machining the workpiece. The movement axes can be axisymmetric or curved. A Turned Part or a Machined Component is a component that has undergone turning operations. This method is used to create prototypes and limited runs. It’s also a popular choice for fine-tuning features on parts. Due to its tight tolerances and high surface finishes, a turning machine is popular for precision rotational features.

Turning Machine Characteristics and Usage:

- Turning machines are used for the rough and finished machining of metal workpieces.

- These machines, which can create end surfaces and internal apertures, are widely utilized in various sectors. They can make small and large pieces, prototypes, and tools. This machine can achieve the highest levels of accuracy and precision, making it excellent for adding rotational elements to items. However, many of these machines are prohibitively expensive, making them only appropriate for small and medium-sized organizations.

- A turning machine’s main components are a bed and a spindle.

- A machine’s bed contains all components, including the motor and driving system. The headstock assembly is the machine’s front part, which includes the headstock assembly and the spindle, both of which support the workpiece.

- Depending on the material, the turning machine can conduct various tasks.

—-

For more details and queries about die tooling, contact our professionals at Prototool.