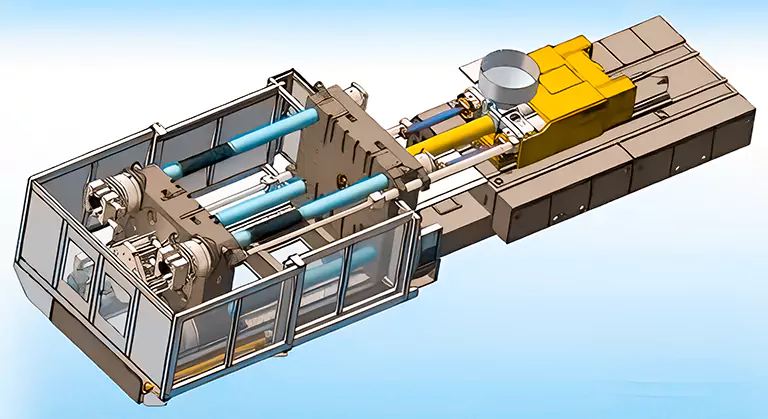

Are you planning to purchase an injection molding machine that meets all your production demands? Is this your first time stepping into the production niche by purchasing an injection molding machine for your manufacturing setup? Then it’s important to be familiar with the important parts of the machine and how you can consider them wisely when purchasing. Having said that, an injection molding machine consists of a clamping unit, an injection unit, and a machine bed. Typically, different clamping units found in such machines work and offer different types of quality in production. So, which machine is a cost-efficient investment with an effective clamping unit?

It’s only possible if you know what a clamping unit is, what it does, and what features you should consider when picking one. This blog will help you discover everything, so keep reading to learn about a clamping unit.

What is a Clamping Unit?

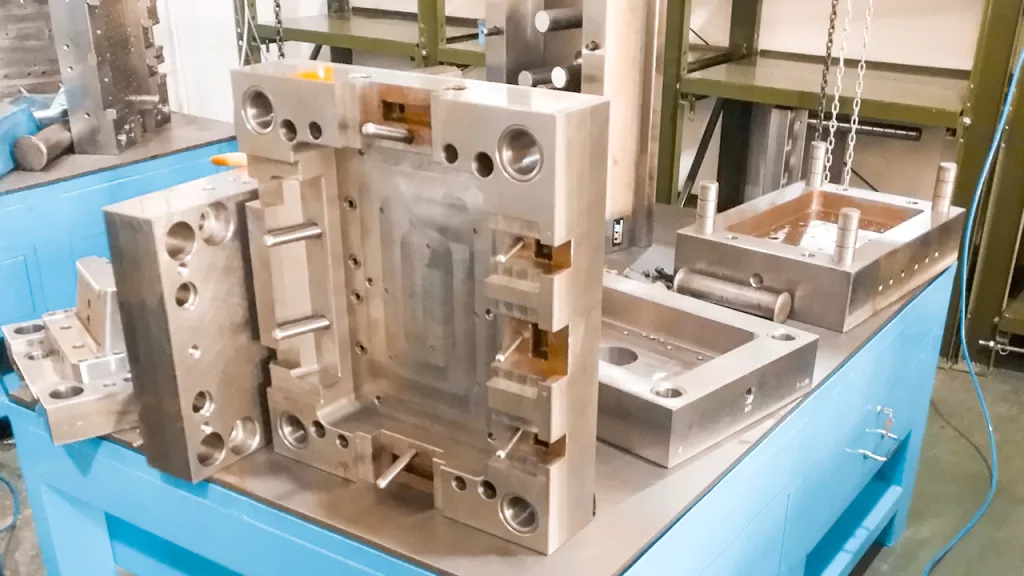

Clamping devices maintain the mold closed against pressures created when injection pressure pulls plastic into the closed mold. As a result, the clamping force must be at least equivalent to the injection force.

Now let’s go ahead and further explore the importance and uses of a clamping unit.

Importance of a Clamping Unit:

The clamping mechanism is one of the most critical factors when producing high-quality products through injection molding. In fact, the clamping mechanism of the five-point double-toggle is more commonly used in high-speed plastics injection molding machines.

Multi-body dynamics analysis, this research aims to improve the performance of a five-point double-toggle clamping mechanism. This work also provides instructions and a clear knowledge for developing the clamping system in an injection molding machine that may apply various clamping forces.

According to this investigation, the theoretical calculation was addressed first, followed by the validation of the computational model. In addition, clamping forces affect the primary dimensions, such as the thickness of the movable and fixed plate, the diameter of the tie-bar, and the average cross-section of the link, which have been explored theoretically and numerically.

Moreover, according to the findings, the ideal design makes achieving a high force amplified ratio possible. The resulting mechanism has good kinematic performance and operates stably with reduced energy consumption and a cheaper cost than the preliminary design.

Additionally, the results reveal that the optimal design allows for a higher force-amplified ratio. In addition, the work has discovered the correlations between the various parameters, such as the ratio of force amplification, the critical angles of the double-toggle clamping mechanism, and the stroke of the moveable mold.

The enhanced parameters will generate relevant knowledge that individuals can apply in designing and manufacturing the clamping mechanism of the microinjection molding machine.

Different Types of Clamping Units Used in Injection Molding:

Clamping the injection mold is the job of the unite doing clamping. The clamping pressure is designed to be greater than the injection pressure to prevent the mold from opening up while the plastic melt is injected.

Below are some similar types of clamping units you can consider when choosing an injection molding machine:

Manual Clamping:

Manual clamping is only observed in the case of manual or hand injection molding machines or occasionally in pneumatic injection molding machines. Pneumatic injection molding machines can also occasionally use manual clamping.

The competence of the operator is what determines the quality of the clamping. It is not possible to measure the clamping force because it is direct. The sprue’s location concerning the nozzle’s axis is an extremely important consideration. The injection of the component from the mold is a challenging process.

Hydraulic Clamping:

Hydraulic clamping entails closing the mold with the assistance of a clamping unit that is actuated by a hydraulic cylinder and is directly connected to the movement; in this scenario, the RAM of the hydraulic system is tied to the moving platen. A hydraulic cylinder has two halves corresponding to the oil’s inlet and outflow.

When oil is forced into the cylinder under pressure, the oil pushes the RAM in the forward direction. This causes the moving platen to move, which in turn causes the mold to close. And as oil emerges from the cylinder, the RAM springs back into action, and the mold breaks open.

Also Read: Plastic Injection Molding Processing: The Best Rookie Guide

Toggle Type Clamping:

A mechanical device that works to increase force is called a toggle. In a molding machine consisting of two bars connected and to end with a pivot, the pivots at the ends of the bars act as a pivot.

One end of a bar is fastened to a platen that is fixed in place, while the other end of a different bar is fastened to a platen that can move. The toggle is shaped like a V when the mold is opened; when pressure is applied to the pivot, it forms a straight line between the two bars.

Tie Bar Less Clamping:

A tie bar-less clamping system is a hydraulic clamping system that does not use any tie bars; instead, the platen is moved along a rail system.

The fact that no restriction is placed on the mold platen size is the primary benefit of the method. Since there is no tie bar, the mold dimension is not nearly as significant as it would be. Additionally, installing the mold is simple, and the fact that items can be manually ejected from the mold is a really helpful feature.

Hydro-Mechanical Clamping:

This clamping system mixes a toggle and a hydraulic clamping system; a hydraulic cylinder is activated to move the toggle. This type of clamping is known as hydro-mechanical clamping.

3 Key Uses of a Clamping Unit:

As a crucial part of the injection molding machine, a clamping unit helps in the following:

Securing the Mold:

One of the primary uses of a clamping unit is to secure the mold to prevent it from being blown apart during the casting process.

It fits the bill with the mold. While the injection unit was injecting the molten plastic into the mold cavities, the clamping unit was responsible for locking the mold securely against the pressure within the mold and preventing the mold from being blown open.

Ejecting Plastic Products:

Ejectors are responsible for removing the mold platen to remove the plastic products. Clear up the mold’s cavity to prepare for the following cycle.

Changing the Dimensions of the Platen To Make it Fix The Mold:

Adjusting the position of the moving platen, also known as the second platen, is the primary adjustment needed to achieve the desired mold thickness parameter.

Observing All Safety Procedures:

The clamping unit’s safety function is the device’s protection base. Workers are protected against clamped by the clamping unit in multiple ways, including mechanically, hydraulically, and electrically.

The gripping force is substantial, yet the human body is surprisingly delicate. In this situation, prioritizing safety measures is crucial. It is against the law to dismantle the safety mechanism of the machine to make it more user-friendly.

Additional Uses:

Other operations, like the core puller and others, are simply there to allow the mold to carry out additional actions while the machine is operating. This function will connect to the controller so that the controller can concentrate its control over everything.

How to Choose an Injection Molding Machine With an Effective Clamping Unit?

Some common aspects you should consider when choosing a clamping unit include the following:

Containment:

Containment requires that the width and height of the mold be less than the inner distance of the huge column or that at least one side of the mold is smaller than that distance.

In addition, the dimensions of the width and height of the mold should ideally be within the dimensions of the mold plate’s size range. Another aspect to consider involves placing the mold’s thickness somewhere between the injection molding machine’s minimum and maximum mold thickness.

Read More: Rubber Molding: The most complete and Definitive Guide In 2022

Lockability:

Lockability occurs when the raw material is pumped into the mold cavity at high pressure. This causes the material to generate a force that supports the mold. Therefore, an injection molding machine’s clamping unit must exert sufficient “clamping force” to stop the mold from being opened.

Takability:

To ensure takability, the opening stroke of the mold must be at least twice as long as the end product’s height in both the opening and closing directions of the mold, taking into account the length of the sprue. Ejecting the finished product should be possible with a single stroke of the mold-supporting mechanism.

—-

Do you still have queries? Welcome to connect with our professionals at Prototool.com.