In today’s fast-paced world, the manufacturing industry is one of the most innovative, always setting new norms. In this growing and evolving industry, gas-assisted injection molding is an innovative plastic manufacturing technology that produces high-quality products.

Today, we will dive further into the manufacturing process by discussing what it is and its various types, applications, benefits, and more.

What is Gas Assisted Injection Molding?

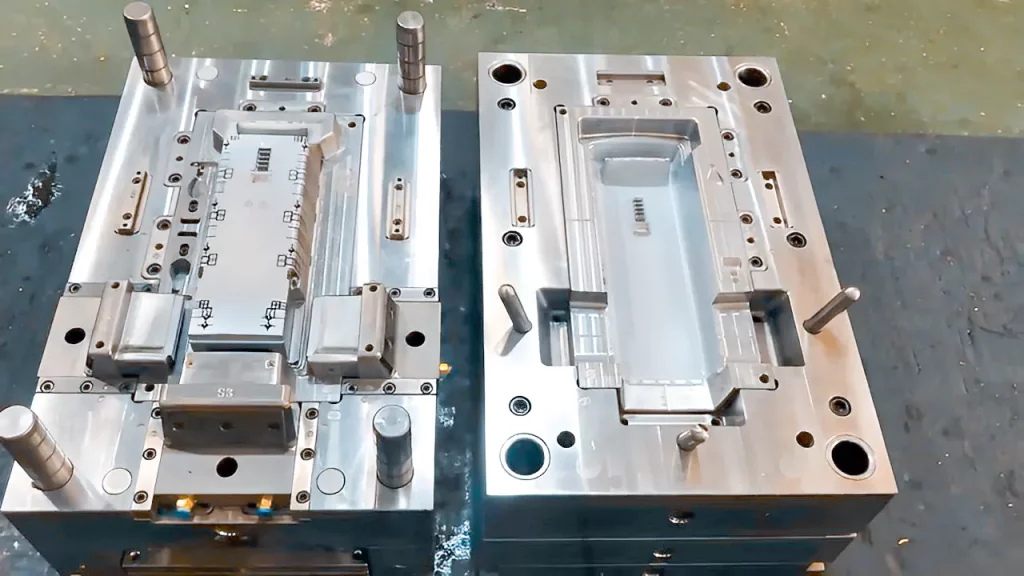

Gas-assisted injection molding is a plastic molding process that combines standard injection molding principles with the use of pressurized inert gas. It employs mold cavities in the shape of the product. 70%-80% of the mold is filled with molten plastic raw material. Filling the remaining volume with Nitrogen gas packs the plastic substance against the mold’s walls.

It is a popular method for producing huge, hollow, molded plastic pieces. It has various advantages, including exceptional surface polish and geometric correctness.

The Process:

To realize the injection, pressure holding, and cooling processes, pump high-pressure inert gas (nitrogen) into the molten plastic to generate a vacuum suction and push the molten material forward.

Because the gas has high-efficiency pressure transfer, it can maintain consistent pressure in all sections of the air channel, eliminating internal stress, preventing product deformation, and considerably reducing pressure in the cavity, eliminating the need for high pressure during the molding process. Clamping force can also reduce product weight and remove sink marks.

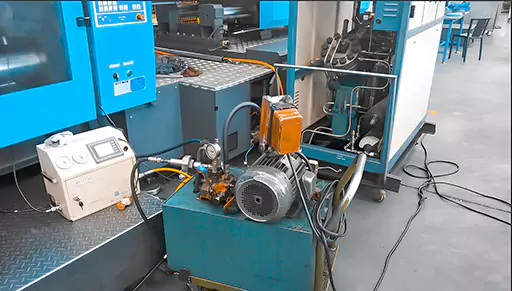

This procedure uses gas-assisted equipment named a gas-assisted control unit and a nitrogen generator, which are part of the gas-assisted injection molding process gas-assisted equipment. It is a separate system not connected to the injection molding machine, and its sole interaction is the injection signal connecting line.

After transmitting an injection signal injection start or screw position to the gas-assisted control unit, the injection molding machine starts a gas injection process, waits for the next injection process to deliver another injection signal, starts another cycle, and so on.

The gas used in gas-assisted injection molding must be inert (often nitrogen) with a maximum pressure of 35MPa, a maximum pressure of up to 70MPa, and a nitrogen purity of 98%.

The gas-assisted control unit is a device that regulates the time and pressure of gas injection. It has a multi-group gas circuit architecture allows it to control the gas-assisted production of numerous injection molding machines at once. Furthermore, the gas-assisted control unit incorporates a gas recovery function to limit gas consumption as much as possible.

Types of Methods to Conduct Gas-Assisted Injection Molding:

There are two types of gas-assisted injection molding processes: exterior and internal. It also adheres to a specific process consisting of three parts. In the following sections, we distinguish between the two categories and walk you through the process.

Internal Gas Induced Molding

Because internal gas-aided molding is more extensively used than external gas-assisted molding, we will cover it first. Molten plastic resin first enters the mold through spruce passages. The gas then enters the molten resin through a nozzle, producing a bubble. The pressure of the expanding gas bubble pushes the resin against the mold walls, giving the pieces their shape.

This method is ideal for producing hollow, lightweight shapes. Also, the gas exerts steady pressure on the resin, which aids in the reduction of shrinkage and distortion/warpage. These variables are typically the primary cause of diminishing dimensional accuracy in thin walls. Thin-walled pieces are hence another unique application of this technology.

Internal gas-assisted molding also has much shorter cycle times. Because the geometries have hollow areas and narrow cross-sections, they cool down faster than solid parts.

External Gas Induced Molding

Exterior gas-assisted injection molding is fundamentally different from internal injection molding. The gas does not enter the material, resulting in hollow regions. Rather, it enters the mold through microchannels on only one side. It applies pressure from the backside/non-aesthetic side of the part to pack the molten resin against the mold’s walls.

This method is well-known for producing a high-quality surface finish. Because the gas pressure acts uniformly on the non-aesthetic side, the opposite end packs snugly into the mold extremities, acquiring its exact shape. The resulting surface is so exact, including the mold’s subtle textures and patterns. As a result, if the part contains surface patterns and imprints, external gas-aided molding is desirable.

This approach not only provides superior surface quality it provides but also allows for thicker sections due to improved packing and shrinkage resistance. For ribbed/boss features, the rib/wall ratio can be as high as 1, which is far superior to conventional methods. This gives the molded part strength and stability.

Parts with wide surfaces and curved profiles are also handled effectively. The gas channels parallel the entire surface, allowing the gas to exert pressure across a large region. As a result, producing huge surfaces is not a significant challenge.

Stages of Gas-Assisted Molding

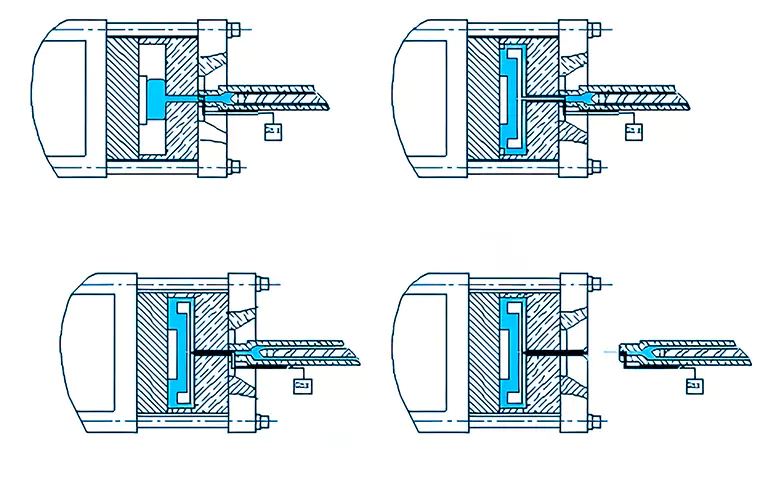

The gas-assist injection molding procedure is divided into three steps (refer to the diagram below). Each stage is a key phase in the process and demands the manufacturing team’s design sensibility and practical skills.

Now let’s go ahead and explore each of these stages.

Injection of Plastic Resin

Initially, the mold clamps are closed, and raw resin is supplied into the injection molding equipment’s hopper. The machine melts and pressurizes the resin in its screw-feed part, just like in a typical injection molding operation.

External heating and friction cause the resin to melt, while the screw’s constantly decreasing pitch compresses it to pressurize it. Because of the hollow parts, the pressure required for gas-assist molding is lower than for conventional injection molding. Furthermore, because the pressure is generated by gas rather than a thick, viscous liquid, there are fewer viscosity-based frictional losses inside the pressurized media.

This molten resin is then injected into the mold cavity. Nevertheless, the resin injection mechanism does not entirely fill the mold because the product comprises hollow areas. The amount of resin material injected is proportional to the volume of the part. It is often determined by geometrical elements such as wall thickness, ribbed features, holes, etc. Typically, 70%-80% of the mold is filled with plastic material.

Primary Gas Infiltration

The process of main gas penetration occurs once the requisite amount of resin is introduced into the mold. A pressurized gas source injects nitrogen into the spruce network, causing a bubble within the resin substance.

The molten resin is pushed to the mold’s borders by the pressure and expanding volume of the gas bubble. The gas pressure remains constant throughout this procedure, ensuring the resin reaches all corners of the mold and completely fills it.

Penetration of Secondary Gases

The resin begins to cool and contract at the end of the primary gas penetration phase. The gas pressure lowers significantly due to the gap generated by thermal contraction. This can result in part deformations and geometric inaccuracies, neither of which is acceptable.

As a result, there is a secondary gas penetration phase during which extra gas flows into the mold to fill the holes. This ensures a smooth fill and maintains uniform pressure.

Benefits of Gas-Assisted Injection Molding:

Gas-assisted injection molding also benefits manufacturers as an innovative and unique manufacturing process. These benefits include:

Material Saving:

In gas-assisted injection molding, less material is used due to not cramming a mold. This reduced material usage excludes the need to pack the material, resulting in a hollow core in thicker components and saving up to 40% on the material utilized.

High Efficiency:

Because of the numerous gas channels, gas-assisted injection molding has a distinct advantage in this area. These pathways allow the gas to readily and swiftly infiltrate all mold sections, which a viscous liquid cannot do. As a result, the final item has a consistent pressure distribution and lower internal tensions.

Decreased Cycle Times:

The cycle time in this manufacturing during the manufacturing of thick-walled products is reduced by 50% or more when compared to traditional injection molding. This reduced cycle time is acquired because there is no molten core to solidify, and the material in the mold chamber hardens faster, allowing the component to be ejected sooner.

Lower Manufacturing Defects:

Flow markings, sink marks, internal tensions caused by non-uniform pressures, and shrinkage after cooling are frequent issues in injection molding. The finished product, however, is free of sink marks since the subsequent gas penetration phase compensates for shrinkage.

Smooth Surface Finish:

The pressurized gas’s homogeneity ensures steady pressure at all spots inside the mold. This contributes to an extremely smooth surface.

High-Dimensional Accuracy:

Tight geometric tolerances are achieved due to the consistent packing of the resin substance. The mold shapes the exterior surface, while the homogeneous pressure distribution of the gas shapes the inner surface.

Lightweight Part Manufacturing:

Plastics are lightweight materials in general. They also only partially fill the mold cavity. Each of these variables indicates that the last section is light.

Conclusion:

Gas-assisted injection molding is an efficient, beneficial, and reliable production process for plastic products. However, before you rely on this method, it’s important to consider the limitations, process, and advantages this process offers to understand better if it is an ideal manufacturing approach for your product’s manufacturing demands.

However, if you still have any queries and concerns, our professional team at Prototool is always there to assist you.