Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

High-Quality Designing Tips for Plastic Molded Parts:

Material Selection and its Implications:

Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk.

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part.

Traces in the Sink:

Avoiding dented markings in injection molded items is a constant issue for experienced designers. While the bottom of a rib or boss is advised to have a maximum wall thickness of less than 60% of the vertical face wall, some molders prefer 50% or less. It should be reminded that this is only a guideline and does not ensure that the part will pass QC.

Avoiding dents on cosmetic surfaces during the design and development of injection-molded products is always challenging. Molders are always hesitant to guarantee no dents on the decorative surface if ribs or bosses are put to the opposite side. The difficulty is heightened when the ribs and bosses involved draft. This ribbed detail is an excellent illustration of this. Working closely with your molder may result in easy solutions such as reducing the draft, increasing rib height, or adding extra features to eliminate sinks.

Gate position, tool quality, nominal wall thickness, material, additives, surface finish, color, and viewing angle all influence cosmetic surface flaws. Production difficulties can be avoided by defining acceptable surface quality with the molder before making any of these selections. Before manufacturing begins, reputable molders will disclose honest expectations and backup plans. The molder may advise removing all features from the part, while others may advise using a unique coring process.

Strict Tolerances:

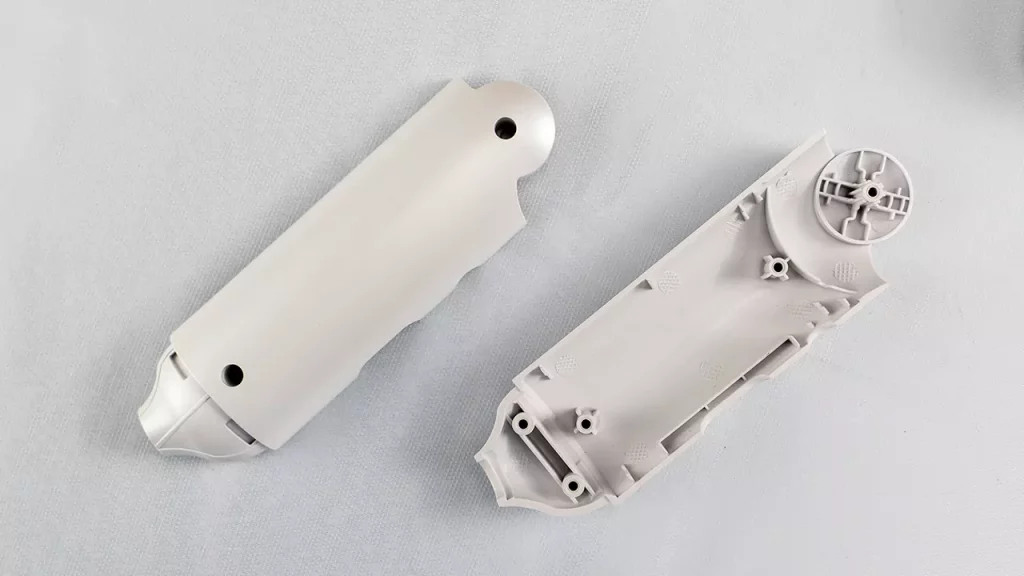

While designers should always provide wide tolerances when practical, tight tolerances are often required to ensure fit, operation, or aesthetics. These photos depict the design details of a set of injection-molded pieces that must adhere to reasonable but tight tolerances to meet aesthetic and functional criteria. The molder is invited to participate in the design review to provide comments and pledges to preserve specifications.

One of the most difficult issues for any designer creating plastic molded parts is giving enough room in the design to accommodate tolerance changes. Several factors affect tolerance variations, including material, process control, and tool design. Tolerance ranges in a design vary depending on the molder. Designers must negotiate realistic critical tolerance standards with molders and, if necessary, investigate mold modification options.

This may necessitate the deliberate design of certain design characteristics and extra clearance to be tightened later by removing the steel from the mold. Nobody wants to correct for interference by welding with steel. Molders may be able to guide how to maintain strict tolerance controls, including post-processing.

Steel Protection Zone

When designing injection molded parts, we frequently encounter elements that necessitate close tolerances, such as snap fittings, alignment functions, or interlocking plastic molded parts. It is simple to align and match these features in CAD, but it is more difficult to generate them frequently during manufacturing.

Now the details that molders can’t reliably recreate are frequently engineered to be “steel safe.” For those unfamiliar with the term, steel safety means that design elements have enough clearance so that toolmakers can readily process steel. The mold was utilized to tighten the gap after the initial molding test. Most molders prefer to take these measures rather than welding the material back into the mold and then treating it.

Welding always has an impact on machining quality, is costly, and delays the start of production. Working closely with a molder or toolmaker early in the design phase reduces design modifications by allowing you and the molder or toolmaker to agree on the important dimensions that should make the steel safe and the amount of clearance included in the design.

These collaborative, well-planned decisions typically have little to no impact on tool budgets and little to no influence on product releases. On the other hand, some molders want the item to be designed exactly as envisioned and do not want to add clearance. That is why it is critical to maintain open lines of communication with the molder of your choosing.

Draft Angle Orientation:

When generating a design and translating it into a functional injection molded item, draft angles should be included on all surfaces in line with the draw. The draft orientation is visible the majority of the time. In rare situations, though, the draft may be angled toward the core or cavity. These choices impact tool design, component fit, parting lines, and cost.

In some cases, the parting line placement may overly complicate the mold and raise tooling costs. Addressing these issues during the development process guarantees that the product is optimized for minimal cost and maximum performance when it is handed over to the molder for production.

Door Location:

Designers, molders, and toolmakers should ideally specify gate locations. Almost every property of an injection molded item is dependent on gate location. To mention a few, it has an impact on appearance, warpage, tolerances, surface polish, wall thickness, molding, and physical qualities.

Certain designers use mold flow simulation to determine gate design and location. I think it’s acceptable if the molders agree with their recommendations. I can’t entirely agree with the designers who insist on being unwavering in their door advice. Working closely with the molder throughout the design cycle will guarantee that the gate has no negative impact on component performance, appearance, or fit.

Also, molder manufacturers are willing to assist designers with the sort of door to use and the characteristics that may need to be added to the part geometry due to the gate design. Molder will also create trade-offs between various gate kinds, such as fan gates, edge gates, and gate gates.

Wall Thickness:

Creating molded pieces with consistent wall thickness will help you avoid different design problems that can occur throughout the manufacturing process. When the material melts, it migrates to low-resistance areas. Depending on gate placements, if your part has variable thicknesses throughout, the melt may first pour into the thick areas.

When this happens, the thin plastic molded parts may not be sufficiently filled. Furthermore, thicker portions cool more slowly and are more likely to have voids or sinking defects. Rounding the edges of your part will also aid in effective part filling during the molding process.

Designing Plastic Molded Parts: Why is it a Critical Process?

Even with modern technological advancements, plastic part design flaws are only detected after the project team thoroughly inspects and evaluates the first article component. Hence, even with today’s sophisticated mold flow simulations, 3D CAD interference tests, quick prototyping, and a plethora of other development tools, no one can forecast every possible issue with an injection-molded product.

It makes no difference how well you design your injection molded product; you should collaborate with your desired molder as early in the design phase as possible. Each molder nowadays has its tool preferences and molded part technology, which can considerably impact component design.

However, it is frequently difficult for designers/engineers to establish this relationship early in the design process because the selection of molds is frequently postponed until the design is finalized and the purchasing department releases the official quotation.

Overcoming Challenges in Collaboration with Mold Makers for Plastic Molded Parts Design

Furthermore, many molders do not provide any input before the project is awarded to them. Because of tool complexity or long cycle times, designers cannot follow these guidelines, resulting in unacceptable delays or cost overruns. These rules are not cost-effective in the long run because they impair product development efficiency dramatically. There are, however, some straightforward answers to this problem.

The first option, which large corporations commonly utilize, is to develop a short list of favored providers based on a detailed study of workers by internal experts. Engineers frequently have access to this limited selection of three to four preferred molders and toolmakers throughout the development process due to mutually beneficial commercial ties.

Smaller businesses can select one or two viable molders early by developing trustworthy business ties. This informal handshake agreement necessitates that both parties agree on the expected costs and terms of doing business with one other. While no guarantees can be made, alliances can be formed as molders and designers exchange their experiences throughout the design development process.

Hence, it should be emphasized that developing high-quality plastic molded parts necessitates the designer comprehending all the basic injection molding design criteria and being a technician in the field.

Summing Up:

Handling the plastic molded parts design process can be critical to ensure that the part production is handled effectively. After all, the lack of high-quality part design not only affects the quality of the product but also delays the overall production timing and delivery of the product.

Therefore, designers must be familiar with every aspect of designing plastic molded parts and handling every process effectively.