The unscrewing mold is one of the most interesting varieties of injection mold. Because of their commonplace nature, you might assume that carefully considering the necessary design is unnecessary.

Now let’s dive in and find out what this type of mold is, what we should keep in mind when working with this mold, and more to show how commonplace it is.

Keep reading to learn all about an unscrewing mold.

Also Read: Identifying and Correcting Short Shots – A Common Problem Faced During Injection Molding

What is an Unscrewing Mold?

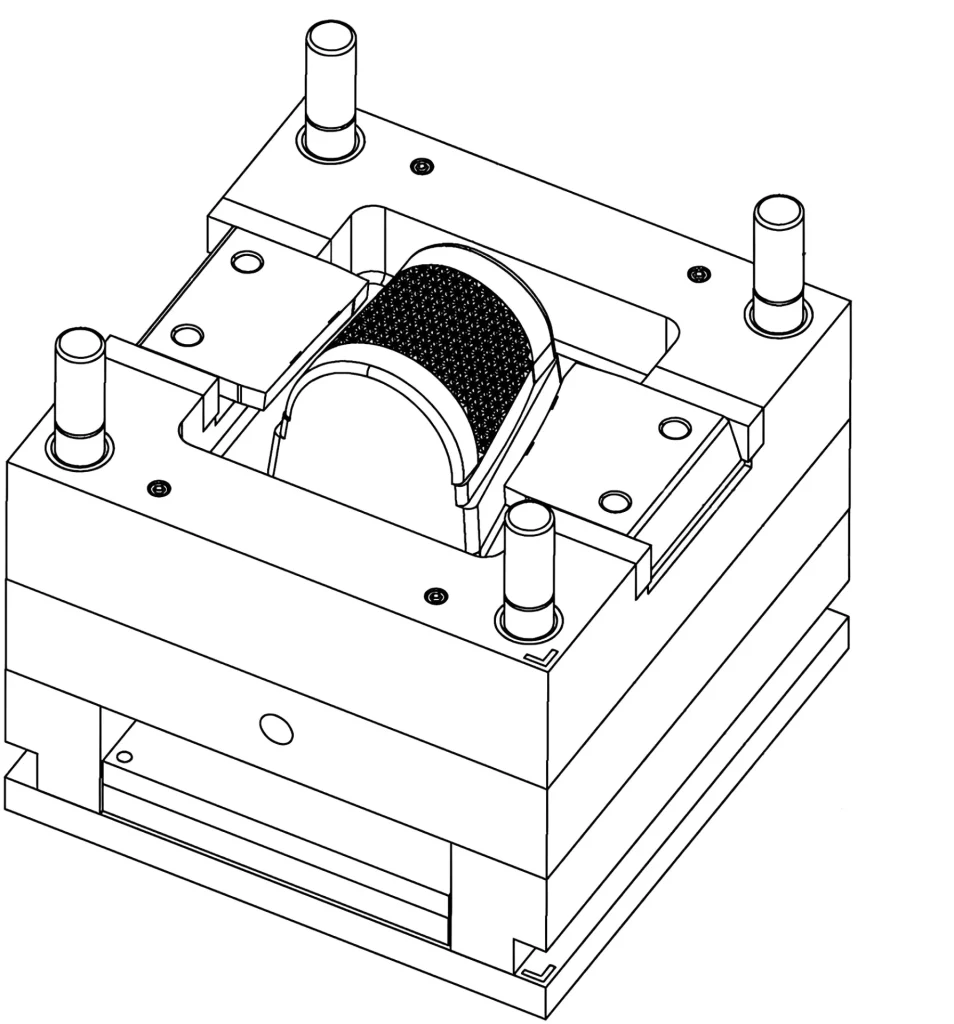

Unscrewing molds are one of the most exceptional varieties of injection molds. Unscrewing molding is a one-of-a-kind injection molding process that produces threaded components through mold technology that incorporates movement and rotation.

This kind of mold is crucial in the production of:

- Medical supplies

- Sprinkler and showerheads

- Bottle and milk caps

- Prescription medication bottles

- Condition and shampoo lids

- Screws, nuts, and bolts

Working Mechanism of an Unscrewing Mold:

Unscrewing molding is a one-of-a-kind injection molding process that produces threaded components through mold technology that incorporates movement and rotation. You cannot use standard knock-off techniques to remove certain plastic items, such as caps and closures with intricate threading patterns.

After you mold the components, they need to be unscrewed from the mold very gently to avoid breaking the threads. Because unscrewing molds are common, professionals often think they don’t need to spend much time giving the required design any thought. However, this would be a mistake.

Studying the motions required to remove a closure from a bottle is the primary step in getting a handle on how unscrewing mold functions. You’ll learn how to use the tool more effectively.

Now, as you study the motions utilized, you will be startled to realize that when you turn the cap, your hand will automatically rise to the pitch of the threads. This fact will surprise you when you learn it.

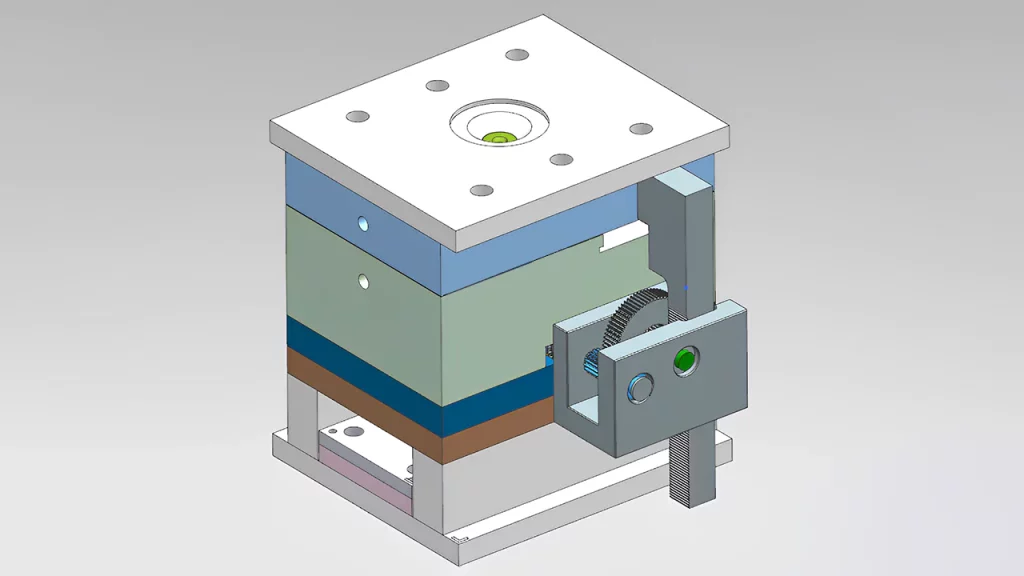

For detaching the component from the core, the cam action on the stripper bar needs to perform the same function. Racks, motors or hydraulic cylinders, and gear racks are the three components that make up unscrewing molds.

Importance of an Unscrewing Mold:

The process of unscrewing molds is an essential step in manufacturing, particularly in sectors of the economy that demand the production of complex parts.

Unscrewing molds allows for creating of more intricate shapes and designs that are impossible with more conventional molding techniques. The method is beneficial in producing threaded parts or hollow products like bottles, syringes, and other medical equipment.

For Manufacturing Complicated Components:

Unscrewing molds offer several advantages, but one of the most significant is their ability to enable the production of intricately designed and detailed complex pieces.

The technique of unscrewing allows for the fabrication of components with accurate threads or undercuts that would be impossible to shape using conventional methods. For example, unscrewing molds are utilized extensively in the automobile industry to produce parts such as gears, bearings, and engine components, all of which require exceptionally high precision and accuracy.

For Limiting Manufacturing Operations:

Unscrewing molds has another goal: to eliminate the requirement for additional operations. You can accomplish this by reducing the time spent on the process. When employing more conventional ways of molding, it is possible that additional processes, such as machining or assembly, will be required to produce the desired shape or design.

On the other hand, parts can be produced with high accuracy and consistency using unscrewing molds, eliminating the requirement for any subsequent operations. This reduces manufacturing costs and the time needed to complete the process, making it more effective overall.

For Added Versatility in the Creation of Complex Designs:

In addition, unscrewing molds give additional design versatility, enabling producers to build unique and forward-thinking items. The molds generate parts of varying forms and sizes, simplifying the process of producing items to the customer’s specifications.

As a result, unscrewing molds find widespread application in manufacturing various products, including electrical components, consumer goods, and medical devices.

Unscrewing molds offer several benefits, including the ability to make parts with precise tolerances. This is just one of the many advantages of these molds. The molds have helped create parts with high accuracy and consistency.

This will ensure that each item satisfies the requirements that you have already set. Because of this, unscrewing molds are excellent for producing components that need high precision, such as those used in the aircraft sector.

Also Read: Design Guide for Different Types of Industrial Molds

Different Industrial Unscrewing Mold:

There are three main types of unscrewing molds: hydraulic, mechanical, and servo-driven. Each type has its unique advantages and applications in the manufacturing process. Let’s explore them below in detail.

Hydraulic Unscrewing Molds:

For hydraulic unscrewing molds to function properly, hydraulic pressure helps turn a cylinder, which rotates the mold’s core. A rotary manifold is attached to the rear of the mold. This is where the hydraulic cylinder and the manifold connect. The hydraulic cylinder rotates the core after activation using the rotary manifold, which transfers hydraulic fluid to the mold.

Design and Components:

Typically, hydraulic unscrewing molds feature two hydraulic circuits: one for the hydraulic cylinder and one for the ejection system. The ejection system, which functions independently of the unscrewing process, is used to force the item out of the mold after it is unscrewed.

Servo-Driven Unscrewing Molds:

An electric motor helps operate servo-driven unscrewing molds. This motor drives a gearbox, which turns the mold’s core. On the back of the mold is where you’ll find the rotary manifold, which is where the motor is attached to. The rotary manifold transfers power to the motor, which rotates the core by driving the gearbox.

However, you may often find the threaded section of the molded item unscrewed from the core of the mold thanks to the rotation of the core, which makes it easier to eject the part from the mold.

Design and Components:

Closed-loop control systems are used in servo-driven unscrewing molds, allowing for high precision and accuracy. The control system monitors the position and speed of the motor with sensors. It changes the power output as necessary to maintain the desired level of precision.

As a result, servo-driven unscrewing molds are perfect for creating parts with complex patterns and threading.

Mechanical Unscrewing Molds:

To remove the mold’s core, molds that unscrew mechanically consist of a cam or gear system that performs this function. These molds work using a motor or hand crank, spilling the cam or gear mechanism and unscrewing the mold’s core. It is possible through the removal of the core of the mold. As the core spins, it detaches itself from the threads on the molded part. This makes it possible for the part to be released from the mold and taken to its final destination.

Design and Components:

Mechanical unscrewing molds are basic in design and operate pretty easily. They don’t need complicated control systems, and the user can adjust the mechanism manually to reach the required level of unscrewing. However, mechanical unscrewing molds do not reach the same level of precision as hydraulic or servo-driven unscrewing molds.

Conclusion:

Unscrewing mold is a unique and complex method used to create plastic injection molded products, which is predicted to become a market worth USD 476.46 billion by 2028.

Now due to its complex operating design and mechanism, it’s important to be familiar with how to understand if this molding method fits your production needs. At Prototool, our experts help you understand the entire process in detail.

Contact us today for further details and consultation.