Plastics, used in all industries, provide adaptability and strength in various applications, from vehicle body parts to human body parts. Each application needs a distinct manufacturing technique capable of molding the part according to specifications. Both thermoforming and injection molding, two of the most prevalent manufacturing procedures for creating plastic parts, have distinct advantages depending on the application.

Now, if you’re looking for a manufacturing process that matches your budget and production needs, it’s critical to grasp the difference, benefits, and process of thermoforming, as well as how it differs from typical injection molding.

To assist you, we will go through everything about this manufacturing process and how it differs from the standard injection molding production procedure. So, shall we delve into the specifics?

What is Thermoforming?

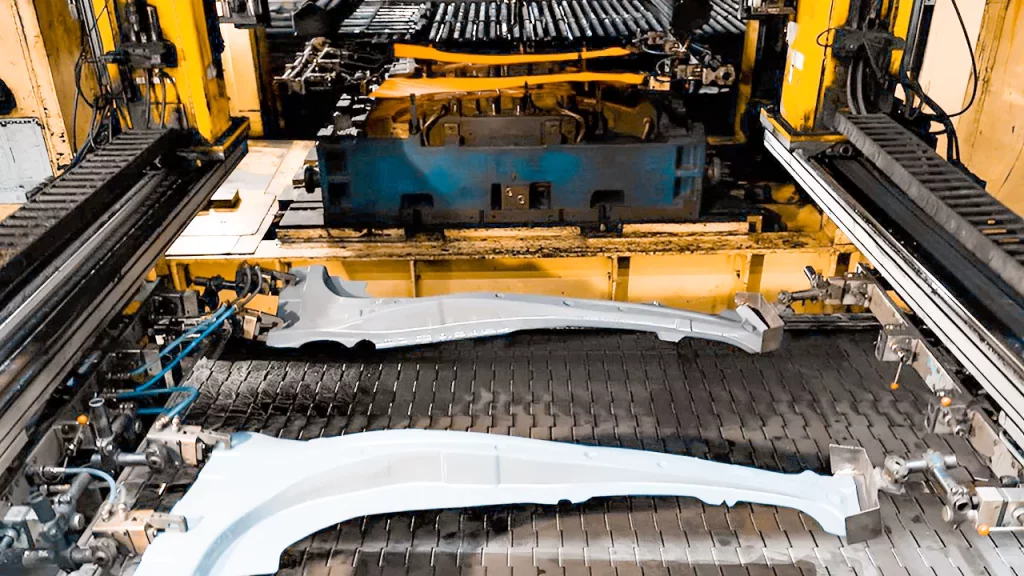

In general, thermoforming creates items by pressing hot thermoplastic sheets into a single-sided mold. Thermoformed items can be created by applying pressure to the sheet or driving all air out of the mold. This technique is known as vacuum forming.

Hence, when an item has been formed, it is cut and finished to customer specifications. This manufacturing process is great for simple geometries and parts with wide tolerances, such as packing inserts, but it is not suited for small, intricate parts or high-volume production.

History of Thermoforming

The concept of thermoforming dates back to 1855, when cellulose was invented. One of those credited with developing injection molding, John Hyatt, experimented with using cellulose as a raw material to make a tougher plastic. With his experiments, he combined nitrocellulose, camphor, and alcohol and began to make the material sheets and rods.

Furthermore, he frequently outsourced the final manufacture of products such as toys, bottles, and other items to other companies. This manufacturing process is now used to manufacture a wide range of goods, from toys to whole bathtubs and vehicle dashboards. Unlike injection molding, thermoforming tooling costs less, and big components can be produced fast for low-volume orders.

Thermoforming Benefits

High Adaptability and Simple Operation

Because thermoforming employs a basic single-sided mold constructed of highly formable materials, thermoform designs can be updated fast and affordably. Injection molding, on the other hand, necessitates two molds with heavier materials that are more time-consuming and expensive to the tool.

Product Texture, Color, and Design Varieties

This manufacturing process has numerous advantages for product design and branding. Vivid colors can be introduced into thermoformed polymers, allowing for vibrant, long-lasting coloring throughout the material. Furthermore, thermoform materials accept painting, silk screening, printing, stenciling, and coatings, which enable distinctive designs, textures, and finishes to improve the appearance and lifetime of the product.

Reduced Tooling Costs

The tooling for thermoforming is less expensive than that for injection molding. Its molds are frequently built of low-cost aluminum. In contrast, injection molds are often made of thicker aluminum, steel, or other heavy alloys to withstand higher pressures and allow continuous reuse over longer manufacturing runs.

Also, this manufacturing process uses a single-sided tool rather than a double-sided injection mold. This results in nearly half the material used for mold-making, lowering the initial cost of thermoforming. Nevertheless, the molds are less robust and cannot be used for large-scale or repeat manufacture.

The size of the component has a considerable impact on thermoforming’s cost-effectiveness when compared to injection molding. The greater the component’s size, the greater the disparity in tooling costs. As the part size rises, this manufacturing process becomes more cost-effective.

Rapid Manufacturing and Prototyping

Regarding product development and prototype testing, thermoforming is far faster than injection molding due to the rapidity with which its molds may be manufactured. Injection mold tooling takes longer since the molds are double-sided and made of tougher materials such as steel. In comparison, thermoform molds are easier to design, build, and change, making them excellent for development and testing.

What is Injection Molding?

Plastic injection molding or Injection molding necessitates significant advanced design and engineering to create complex tooling or molds. Split-die molds, made of stainless steel or aluminum, are injected with molten liquid polymers at high temperatures and under great pressure. The molds are then cooled to release entire plastic pieces.

The Advantages:

Plastic injection molding has various specific advantages of its own, including:

Detailed Tooling for Complicated Parts

Injection molding has a significant benefit in that it enables the production of highly intricate components with an exceptional level of detail. Because the material is pressed firmly into even the smallest precise cavities, the tremendous pressure utilized in the injection molding process enables the manufacture of complicated components and odd geometries. With multi-cavity mold options, the injection molding process can be modified to fit individual needs.

High Precision and Efficiency

Injection molding includes the use of long-lasting and reusable molds for numerous runs. Customers may rely on the mold to deliver accurate, consistent results for big production runs over many years.

The approach is especially beneficial for extremely small, complex, and detailed components that are time-consuming or difficult to fabricate using thermoforming, cutting, milling, and other manufacturing methods.

Cost Savings in Plastic Injection Molding

Although injection molding is more expensive than thermoforming, the mold design and manufacturing process can be altered in various ways to minimize total production costs. Simplifying and simplifying the design can help cut costs associated with manufacturing intricate molds.

Furthermore, adopting material reduction procedures like undercutting and coring or simply changing molds from a similar product may provide a way to meet the needs of a new project on a budget.

Effective Material Use

Injection molding is a very efficient technique with extremely low scrap rates. Each component’s material is accurately measured to ensure the mold is filled, resulting in little overflow or waste. After being released from the mold, an injection molded product can be produced to scale with little extra tooling.

Plastic injection molding is perfect for large-volume orders and mass production in projects that require thousands or even millions of the same part.

The Comparison: Thermoforming vs. Injection Molding

Volume Comparison

Injection molding can accommodate substantially higher production volumes than thermoforming. This is because injection molds might have many cavities. Some molds can have over 100 cavities. However, this process produces only one item during each molding cycle. As a result, injection molding is far superior for big or regular production orders.

Speed Comparison

Both injection molding and thermoforming are excellent at making parts quickly. The key difference is that with injection molding, molds can sometimes have numerous cavities fed by the same supply of molten material, resulting in substantially higher output. Because the tooling of this process is easily adjusted, the development of the final product design and molds is accelerated.

Material Comparison

Injection molding and thermoforming can employ the same plastic materials, such as polyethylene, polycarbonate, and PVC. Because injection molding employs plastic pellets while this process uses plastic sheets, thermoforming materials are more flexible and malleable.

Lead Cost Comparison

Tooling costs for this process can be much lower than for injection molding. Because pressures during this manufacturing process are lower than injection molding pressures, most of the tooling in this process is composed of aluminum.

In comparison, injection molding requires costly tool steels such as P20 or H13. Because of the complexity of the molded pieces, fabricating injection molding tooling can take a long time and be significantly more labor-intensive than thermoforming molds.

Which Method Is the Best?

Both techniques may be employed to create plastic parts for some sectors and applications. Yet, many sectors choose a distinct strategy based on the unique characteristics of the project at hand. To identify which procedure is appropriate for your plastic molding task, you must carefully evaluate your project’s particular qualities and requirements.

Injection molding is the best option for projects requiring greater production quantities, particularly complicated or precise designs, short lead times, or automated programming to reduce manufacturing costs. All of these needs can be met by the injection molding method, which can accurately produce huge quantities of high-precision parts in a fast and cost-effective manner.

Instead, thermoforming is appropriate for projects requiring smaller manufacturing volumes, cheaper tooling costs, or parts with color and texture. This advanced process has fast lead times and wide aesthetic possibilities for larger items with simplified designs.

Whether working with plastic pellets for injection molding or plastic sheets for thermoforming, both procedures ensure high reliability and quality. The application’s unique requirements will determine the best alternative for a single work.

For more details and queries, feel free to contact our professionals at Prototool.