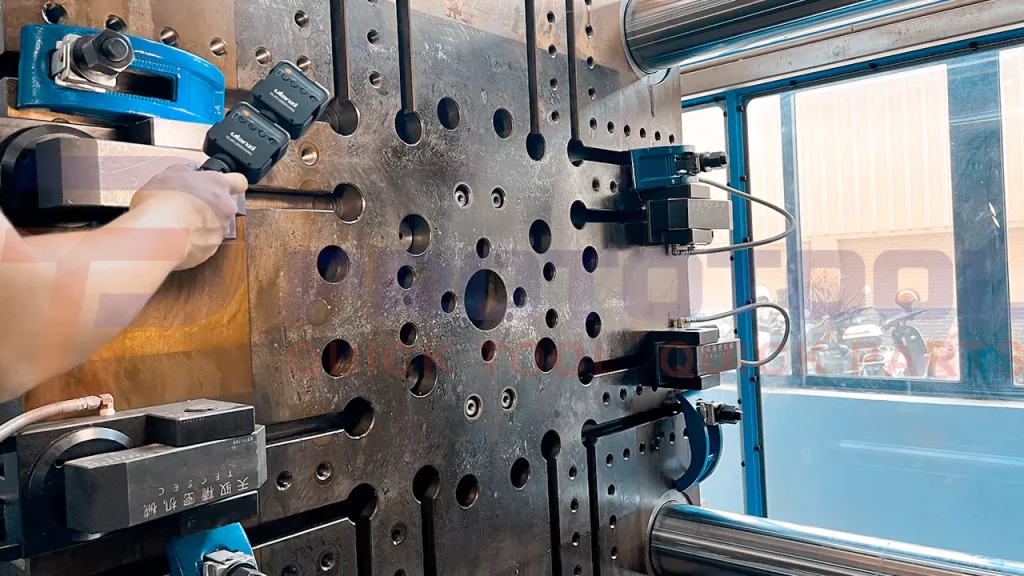

Injection of plastic moulding is a technique that involves combining plastic with a binder ingredient to generate a feedstock that is then shaped and hardened by plastic injection moulding. High-volume, complicated items can be formed in a single phase using the moulding method. Following moulding, the part is treated to remove the binder (debinding) and densify the powders. Finished products are small components employed in various industries and applications.

Here is a complete analysis of the market, prospective growth, and new developments in plastic injection moulding in the coming years.

The Plastic Injection Moulding Market Analysis:

Due to the COVID-19 pandemic, the worldwide injection moulding plastic market is anticipated to be worth USD million in 2022. It is forecast to be worth USD million by 2028, with a CAGR of% over the forecast period 2022-2028. Taking into account the economic changes caused by the health crisis, Portable, which accounted for% of the worldwide Injection Moulding Plastic market in 2021, is expected to be worth USD million by 2028, increasing at a revised% CAGR from 2022 to 2028. At the same time, the telecom segment has been changed to a % CAGR for the duration of the projected period.

The global Plastic Injection Moulding market will be worth Millions of US dollars by 2027, up from millions of US dollars in 2023, at a CAGR during the forecast period. This report uses 2022 as a base year and 2023-2027 as a forecast period to calculate the market size for plastic injection moulding.

Trends Of Plastic Injection Moulding Market

· A More Engineering-Oriented Approach to the Design Process:

We’ve repeatedly heard that designing for manufacturability is good practice. Still, the emerging trend of a more engineering, integrated approach to product design that prioritizes manufacturability is where things get exciting.

This means that production manufacturability, or the compatibility of a product’s design with the practicalities of a manufacturing process, is being examined considerably earlier in the process, during design and, more often than not, prototyping. This leads to a smoother and faster overall design and production cycle.

By incorporating best practices like rounded corners, support ribs, and other injection moulding realities that are typically presented much later in the process — and thus seen as a compromise — the gap between the initial design and the final product is becoming much narrower, which is a “win” for both the designer and the manufacturer. In other words, the gap between the initial design and the finished product is closing rapidly.

· Moulding is Done with a Microinjection Gun:

The activity of plastic injection moulding items at a tiny scale, sometimes at dimensions down to the micron level, is referred to as “micro moulding,” and it is a buzzword frequently heard in medical device manufacturing. Micro moulding is, in some ways, precisely what it sounds like. However, micro moulding is much more than that, which is one of the primary reasons it has grown so popular in recent years. These minuscule injection moulded elements are vital as other medical device advancements enable smaller assemblies to execute extraordinary, lifesaving surgeries less and less intrusively.

However, a suitable micro moulding vendor must be able to mould parts at such a minute size and possess other relevant skills. Tolerances, part faults, and flaws have to be able to be measured and analyzed by it since, on such a small scale, there is very little room for error. Due to the fragile nature of these components, it is in everyone’s best interest to handle and transport them as little as possible, whether from where they were manufactured or to a facility that specializes in quality control.

In light of this, it is essential for a provider of micro moulding services to have, in addition to the capability to manufacture, the quality control and measurement instruments that are required. Technological advances and increased availability make it much simpler for providers to fulfill this demand.

· Eco-Materials:

Certain manufacturing contracts can require the use of sustainable materials, and these materials are also a topic of broad social concern for many business owners and manufacturers alike. The capacity of a thermoplastic material that can be easily reclaimed by melting and re-integrating any scrap material has been recognized as a significant advantage for the environment for as long as thermoplastic material has been available.

Manufacturers of materials are now taking their work a step further by inventing materials that are non-plastic or less plastic, both of which place less of a strain on the environment throughout the manufacturing process. The vast majority of these materials of the next generation are derived from plants and are manufactured from readily available bases such as corn or flax.

· Sustainable Operations:

In the same vein as the argument made above, maintaining environmentally responsible business practices is not just an issue of social duty but also a condition of many contracts in the modern manufacturing environment. The makers of machines are continuously developing more productive pieces of manufacturing equipment. This indicates that a plastic injection moulding machine bought today can produce the same number of components or go through the same number of cycles while requiring a significantly lower amount of energy than one bought even just five years ago.

· Automation

Automation is a topic that is nearly always discussed on lists such as these, and it has been for such a long time that there are times when it feels like it shouldn’t even be considered an invention anymore. What’s important is that even though automation has always been one of the most concerning topics in discussions about the future of manufacturing (and has been a part of manufacturing for quite some time), innovations continue to occur in the field of automation itself, which is why it continues to be a topic that is worthy of being mentioned.

One of the most promising examples of this may be in the field of robotics, where “smart” robots have become advanced enough in terms of safety to practically work with their human counterparts. This is in contrast to the automated sections typically found in manufacturing facilities, which have traditionally not been conducive to the presence of people working within them. Because of developments in automation, such as co-working environments, robots can make certain aspects of human occupations easier without completely replacing them.

· Both Reshoring and Nearshoring are Options:

It is no longer the usual or automatic assumption that large production employment should be outsourced to other countries as it formerly was. A growing number of start-ups and established companies are realizing that manufacturing facilities closer to home may maintain price competitiveness while frequently outperforming the quality and level of service typically provided by suppliers located offshore. When shipping costs, not to mention lower levels of rejected parts, are considered, the overall price difference between a foreign and a domestic supplier can become negligible. This is offset by a faster time to market and increased reliability in the supply chain.

· Reevaluating the Logistics of the Supply Chain

Apart from the price differences between offshored and nearshored production might often be minimal, the reliability of a supply chain can frequently prove to be beneficial, both for your peace of mind and for your bottom line. Offshoring production can be an option to consider. Uncertainties on a global scale mean that it is no longer obvious that a long-term (or short-term) contract with an overseas supplier is guaranteed to remain a favorable deal. In some instances, these uncertainties may even doubt the ability to complete and deliver orders.

When the entirety of the supply chain is considered, which includes the acquisition of raw materials and their transportation in addition to the fulfillment of the finished product, it becomes abundantly clear that there are plenty of areas in which particulars have the potential to go wrong. Companies are increasingly gravitating toward more dependable and secure manufacturing collaborations so that they don’t have to learn this lesson the hard way.

Conclusion:

So, according to the market study and new trends, we expect to witness in the plastic injection moulding industry, what are you most awaiting?