Plastic injection molding service is widely utilized for producing plastic parts of varying sizes. One needs a mold, some unprocessed plastic, and an injection molding machine to complete the procedure. The plastic is heated to the melting point in the machine, injected into the mold, and allowed to cool and harden.

Products from the automotive, medical, small engine, plumbing, industrial, agricultural, and many more sectors all use plastic components. The most recent advancements in plastic injection molding technology and manufacturing techniques allow for the rapid and precise production of plastic components of the highest quality.

Plastic injection molding has advanced considerably in the previous two decades alongside other industrial methods. No longer are time and pressure the primary factors in molding; instead, position, peak pressure, and process repeatability have emerged as critical factors.

The plastic injection molding services offered by various businesses can differ significantly in process, equipment, methodologies, and approaches. The following methods, however, can help you understand how the top and professional China-based manufacturers, such as Prototool, handle manufacturing services.

How Do Companies Make Injection Molding Machines?

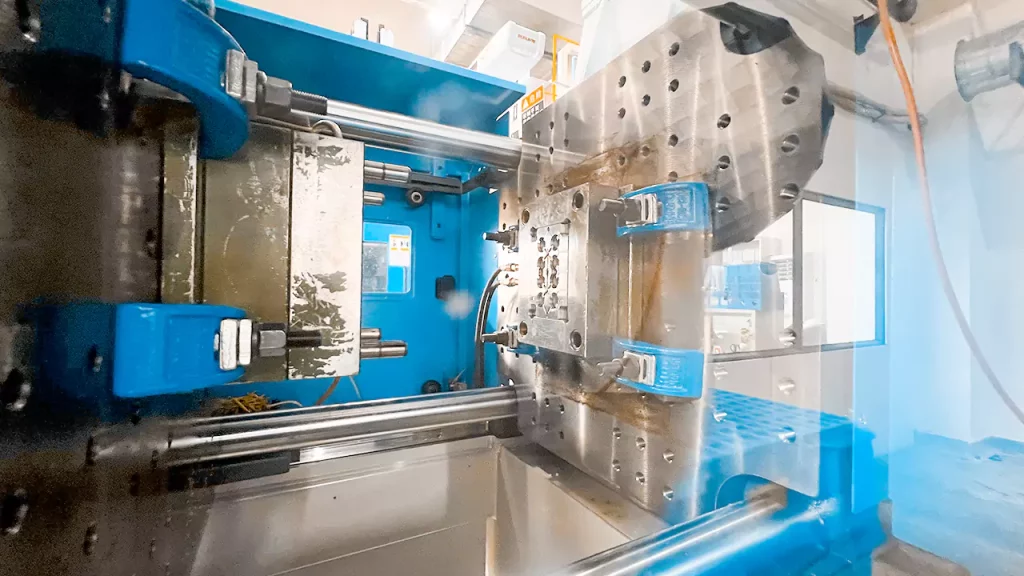

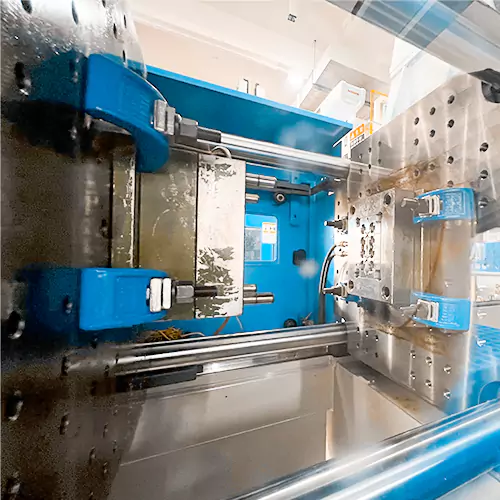

A material hopper, a barrel, an injection ram or spinning screw, a heating device, a changeable pattern, ejectors, and a mold located inside the mold cavity are the components that plastic injection molding service providers use to make an injection molding machine. In most cases, the orientation of the machines’ motion is horizontal.

The ejection of components and the opening and closure of a die are the tasks that are performed by the clamping unit. A toggle kind of clamping is represented above, and a straight-hydraulic type of clamping enables a mold to immediately open and close with a hydraulic cylinder. Both of these types of clamping systems are used.

The electric motor drives the hydraulic rotating screw, placed at the other end of the barrel from where the hopper is located. Plastic is fed into the hopper while the screw is turned to melt it. Following the accumulation of the necessary quantity of molten plastic, the operation of injection can then begin. On the opposite side of the barrel, a mold has been affixed.

The speed of the screw is controlled by the injection molding machine even as liquid plastic flows through the mold (or the injection speed). Additionally, it regulates the pressure as the plastic fills the voids. When the screw position and injection pressure reach a specified value, the speed control and pressure control settings are adjusted accordingly.

How Companies Make Injection Mold?

Injection molds are made of high-strength metal components machined to function in two halves. These molds are used to make plastic parts. The molten plastic enters a mold via a sprue and fills the cavities via runners and gates. The process is called injection molding. Following the completion of the cooling procedure, the mold is opened, and the injection molding machine’s ejector rod presses the mold’s ejector plate to expel the moldings.

For an injection mold to function correctly throughout the process of injection molding, the composition of the injection mold is essential. Although molds typically consist of two sides, known as a cavity side and a core side, there are frequently dozens of precision features that make up each of those halves.

The great majority of machined mold components used in the creation of a custom-molded object are machined to tolerances of less than +/- 0.001 inch (or 0.025 millimeters), which is one-third the thickness of a piece of copy paper. This enables the molds to make parts with unrivaled precision in the industry.

The Post-Processing Approach of Companies:

Many products manufactured using plastic injection molding services require additional post-processing steps after being created using injection molding. Additional treatments for aesthetic or practical reasons may fall into this category. There are typically six different injection molding post-processing uses.

- Gate Trimming

- Laser Marking

- Heat Staking

- Ultrasonic Welding

- Painting

- Pad Printing

How Do Companies Conduct the Plastic Injection Molding Process?

· Clamping:

The cycle time for the process of injection molding is extremely brief, typically lasting anywhere from six seconds to two minutes. The following activities make up each process stage: Clamping: The two parts of the mold need to be firmly secured together by the clamping unit before the heated plastic material can be injected into the mold.

This must be done before the injection process can begin. When the material is injected into the mold, the immense force of the clamping device presses the mold halves together and maintains the mold securely closed. The machine determines the amount of time necessary to close and clamp the mold; more extended amounts of time are required for more complex machines with wider holes.

· Injection:

The raw plastic material, typically in the form of small pellets, is fed into the injection molding machine, and the injection unit either conveys or augers the plastic material to the mold. As the screw moves the plastic pellets through the machine’s barrel that contains heated zones, the plastic material is subjected to temperature and compression changes that cause it to heat up. Once the injection process is complete, the quantity of molten plastic transferred to the front of the screw represents an accurate portion of the object.

The quantity of material injected into the mold is called the shot. Once the clamps have been tightened to their maximum position, the machine injects the material into the mold. It is possible to determine the amount of time required for injection by considering the shot volume, injection pressure, and part shape.

· Cooling:

The molten plastic within the mold will begin to cool as soon as it makes contact with the internal surfaces of the mold. The newly molded piece of plastic takes on its final form and hardness after cooling. Considering the possibility of component shrinkage during the chilling process is essential.

After the necessary amount of time has passed for the mold to cool, it will no longer be possible to open it. Every item molded from plastic has its own unique set of cooling time requirements, which are determined by the plastic’s thermodynamic properties, the part’s wall thickness, and the dimensional requirements for the completed part.

· Ejection:

Once the component has cooled inside the mold, it can be removed using the ejection system once given enough time. Ejection requires a certain amount of force provided by the mechanical components of an injection molding machine. This force pushes the part out of the mold. During this stage of the process, the machine has prepared a new shot of plastic, and once the component has been completely ejected, the mold will be prepared for the subsequent stage of the process.

Plastic Injection Molding Machine Classifications:

It is vital to have an approximation of the size of the press that will be required to manufacture your precise components to select the most suitable injection molding partner based on the press capacity that is now available. Because of this, the machines utilized by reputable businesses that provide the service of plastic injection molding are calibrated following the criteria above. For instance, because they have an excessively high shot capacity, larger presses cannot handle molds with a lower diameter.

For example, injection molding machines are categorized or rated according to their tonnage, which refers to the clamping pressure or force. Presses can range in size from having a clamping pressure of fewer than 5 tons to having over 4000 tons. The larger the press ton rating, the more space the equipment requires. A machine with a rating of 400 tons can apply a clamping pressure of 400 tons. During the injection process, this pressure ensures that the mold remains closed; however, problems with the product’s quality might arise if there is too much or too little pressure.

Conclusion:

All in all, different processes, machine modifications, and port-production approaches are used by different plastic injection molding service provider companies. However, this guide will help you understand what you should look for when investing in such services and how you can trust professional companies to acquire the best quality production services.