The goal of precision injection molding and injection molds, a highly technical technique, is to produce exact plastic components with complex geometries for a variety of industrial applications. Precision injection molding is never utilized to produce whole items. Precision molds, which are essential to the process and which need to be carefully designed and made, are used. If not, there may be a lot of burrs on the plastic components that need to be removed, and deburring can frequently represent a significant amount of the manufacturing expenses. See the information below to learn everything there is to know about precision injection molding.

Precision injection molds: What Are They?

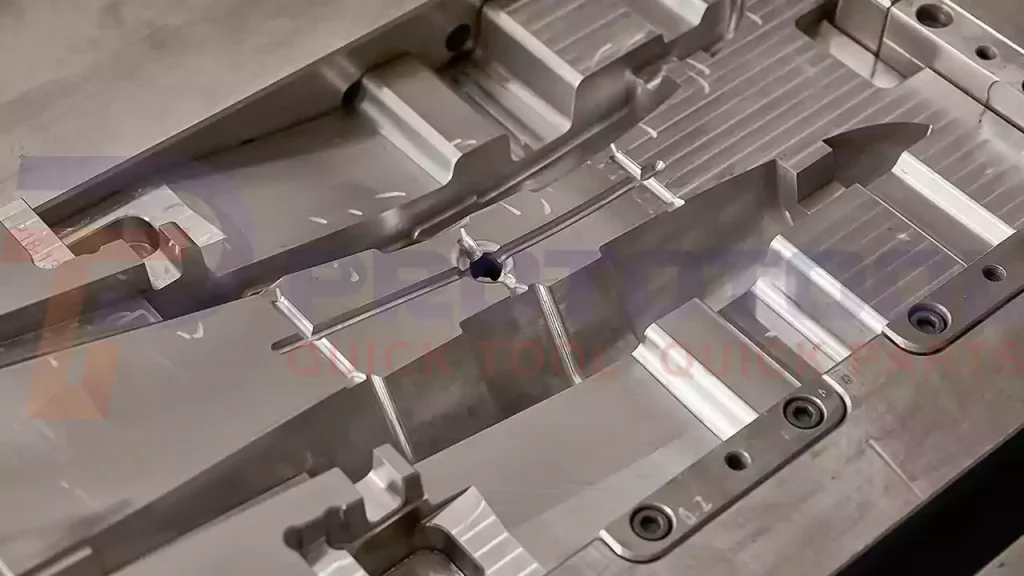

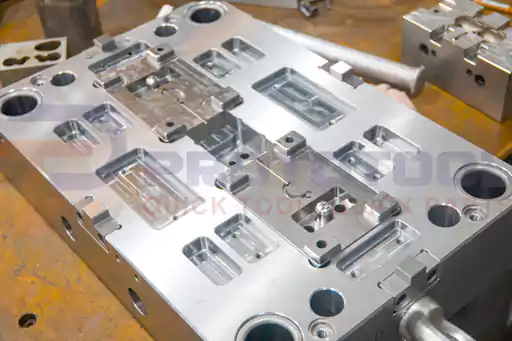

Dimensional tolerances for a precision injection mold are kept to under one-third of those of the items they are used to make. The accuracy of the mold is influenced by the accuracy of the cavity size and quantity in the design, the placement of the cavity, the accuracy of the parting surface, the material choice, and the dimensional tolerance. Important aspects of the precision mold include the thickness of the supporting plate, cavity wall, and bottom plate, as well as the runner size. Equally significant is design engineering. Typically, alloy steel, which has a high mechanical strength, is used to make the mold.

What kind of molds do They serve?

Certain characteristics are necessary for precise injection molds, including

- The number of cavities required to fabricate the component;

- The hollow wall, supporting plate, and bottom plate’s thickness;

- The proper runner size

- It must be built, preferably, from steel alloys with high mechanical strengths and follow engineering design specifications.

How is precision molding carried out?

Precision molding is a fully automated process that is managed by computers using automation management systems. Smooth and individualized production is made possible by the method. Additionally, it goes through several phases that include anything from plastic injection molding to packing, coating, and testing. From the injection mold through the mechanical supports to obtaining the semi-finished item, every aspect of the process mechanics is completely programmable. Several specialized industries use precision injection molding, including those in the automobile, pharmaceutical, medical device, and information technology sectors.

An extra list of precision molding pointers:

- As a result of being more economically viable, this procedure is advantageous.

- Additionally, the method offers a brand-new, much-improved approach to dealing with the optic problems that arise in the contract manufacture of technological goods and scientific molding.

- To create the optical components required for several high-precision goods, the bespoke injection molding process is not the best option.

- Precision injection molding enables the manufacturer to adapt the procedure to the demands of the molded product.

- The development of highly precise molds requires the use of polymer optics in precision injection molding, which also gives the development of plastic injection numerous distinctive advantages.

- The molding industry they are perfect for the mass production of inexpensive products. Before PIM, molding specialists and molding consultants had to create these goods by hand. These items are now developed in a large-scale, extremely precise manner.

- One distinguishing quality of the product that sets it apart from the other bespoke injection molding technologies is integrated optical and mechanical capabilities.

- As a result of the research and development, Precision Injection Molding (PIM) technology was created, enabling injection mold manufacturers to create plastic equipment with high precision and quality control at affordable prices.

- The procedure can be completed in a single easy step without the need for any additional processes. It means that contract manufacturing enables the product to be developed more quickly and precisely.

- Compared to its competitors, the method has a shorter cycle time. As a result, the procedure is more suited for the mass manufacturing of molding materials.

Classification of precise injection molds:

Depending on the type of gating mechanism, precision injection molds can be categorized into three groups.

Gate edge mold:

When the injection mold is opened, the plastic product is demolded jointly along with the runner and gate, which are on the separation line. The design is quite straightforward, it is inexpensive, and it is simple to manufacture. Therefore, Edge gate technology is employed by numerous injection molding companies.

Precise gate:

In most cases, the runner and gate are located directly on the product rather than the separation line. Consequently, a set of gate separation lines must be designed. The processing is somewhat challenging, and the design is slightly sophisticated. The requirements of the plastic part are typically taken into account when choosing the pin-point gate system.

Hot-runner molds:

Generally speaking, hot sprue bushings, hot runner plates, and temperature-controlled electrical boxes make up hot runner molds. Single and multi-point hot gates are common hot runner system configurations. Direct injection of the molten plastic into the injection mold cavity is accomplished by the single-point hot gate using a single hot sprue sleeve. It can be used with a plastic injection mold with a single gate and one cavity. A hot runner plate connects each thermostatic sprue sleeve with a molten piece of material via the multi-point hot gate. Next, the cavity is entered, which can be used for multi-cavity molds or single-cavity multi-point feeding.

The injection mold construction is similar to that of a pin-point gate, with the main distinction being that the runner is in one or more hot runner plates and hot nozzles, necessitating no demolding of cold material. The runner and the gate are also directly attached to the product, negating the need for demolding as well. This system, also known as the waterless port system, can save raw materials and is appropriate for products with high requirements that require expensive raw materials, difficult design and processing, and expensive injection molding.

How to choose the best materials for precision injection molding;

As for characteristics, each substance has its own. Injection molding materials, for instance, vary in their degree of dimensional stability. In a similar vein, some offer superior label adhesion over others. The following factors are taken into account while choosing a material: temperature, pressure, and chemical and biological interactions.

Amorphous and semicrystalline thermoplastic resins make up the bulk of the category. Although amorphous thermoplastics are more impact- and dimensionally stable than semicrystalline thermoplastics, the latter is better at resisting chemicals and electricity. The degree of tolerance needed or particular qualities, like wall thickness, may be impacted by the material chosen.

The factors affecting this process:

When it comes to precision injection molding, selecting a trustworthy partner and supplier is even more crucial because this process is dependent on many factors that affect the outcome, such as the precision of the molds and thermodynamic control. The most typical examples are shown below:

Molds’ overall quality:

Exacting research, testing, and design go into creating molds for precision injection molding. During the manufacturing process, you should pay close attention to some components, including

- Engineering design

- The size of the injection mold cavity, its location, and the number of cavities

- Parting surface precision

- Materials selection

- Measurement tolerance、

- Size of the bottom plate’s thickness

- Runner size

When you take into account dimension tolerances, all of these factors become increasingly important.

The mold’s thermodynamic control:

The water lines in the molds balance the heat loss from the plastic material to create a specified plastic shrink, which requires precise temperature control of the molds. Individual temperature controllers assist in establishing and maintaining the optimum temperature while preventing humidity from condensing and freezing the injection mold surface when the door opens and closes.

Material consistency of plastic:

Depending on the type of plastic, different properties are Physico-chemical. This has an impact on the precision and quality of the injection molding process, so keep this in mind when designing the molds.

The precision of the molding apparatus:

For high-quality outcomes, precision injection molding equipment is essential. In reality, high temperatures frequently alter the viscosity of the oil in the machines, leading to dimensional irregularities.

The following industrial fields need precision injection molding:

Modern technological advances have significantly raised the demand for plastic parts, components, and micro-components with odd shapes and complex geometries for use in cutting-edge technical gadgets. Electronics, automotive, medical technology, optical products, home appliances, and other industries are the ones with the most involvement.

What Advantages Does Precision Injection Molding Have?

Precision injection molding might be an intelligent choice when a project calls for components for a highly technical application and demands a high volume of manufacturing for various reasons:

- Cost-effective:

Precision injection molding’s automation and repeatability enable increased productivity while lowering labor costs. The procedure calls for the employment of automatic CNC machines, which lower labor costs and boost production effectiveness.

- Complexity:

Large volumes of fine detail are possible to generate.

- Design discretion:

For better flexibility and control, the precision injection mold is created specifically for the project’s specifications.

- Strength:

The plastic used can be extremely strong even while being less expensive by adding fillers or blends.

- Efficiency:

Greater speed and the ability to produce more components from a single injection mold are two benefits.

PROTOTOOL is the best choice for all of your precision injection molding requirements. Since they have been in the business for a while, they can readily provide the greatest answers. To deliver a product that satisfies the needs of the customer, their services offer ongoing controls and testing throughout the production process.