Undeniably, injection molding has been an integral element of the manufacturing process for many years now. People use it in various production procedures for daily objects, particularly plastic ones. Yet, few people know how this operates and the several components that need to cooperate to guarantee that the final product meets all of the necessary criteria. Among these components, an injection molding runner is the essential component of an injection molding design, comprising numerous sections.

Now if you plan to produce plastic items for your company or your customers, you must become familiar with injection molding runners, the different varieties of injection molding runners, and which type is best for the plastic product you intend to manufacture. Now that we’ve covered the basics, let’s get deeper into the specifics of an injection molding runner.

What Exactly is Meant by the Term “Injection Molding Runner”?

An injection molding runner is a specialized channel cut into the mold to facilitate the smooth injection of the plastic material from the nozzle into the void space. This is done so that the mold can be used again and again. After the injection has been administered, it plays a significant part in controlling how things go from that point on. The finished product will be affected by even the most minute shifts in pressure or temperature, both of which apply to the material and the mold.

When all of these elements work together, they raise the levels of internal stress in the manufactured product, which might eventually compromise the product’s structural integrity.

Because of the runner’s strong influence on part creation, the injection molding runner solves this problem. It immediately impacts the pressure, the temperature of the melt, the warping, the shrinkage, the packing, and the residual stresses.

Hence, they can be sliced into a wide variety of shapes and sizes, all determined by the requirements of the production process and the dimensions of the object in question. Without runners being engaged, the injection molding process will not be nearly as efficient as it could be. This is the bottom line.

How is a Runner Designed?

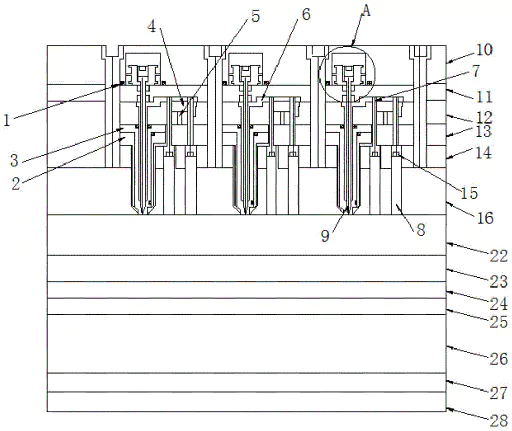

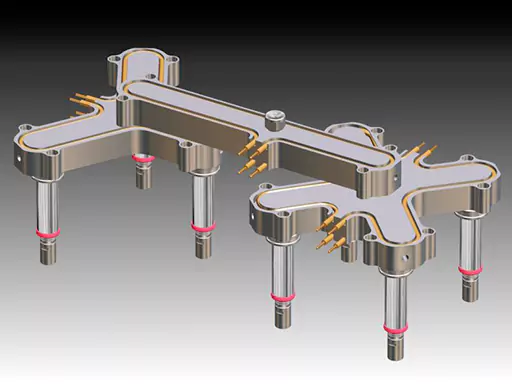

An injection molding runner is essentially the channel that molten material travels through on its journey from the nozzle to the gate of the mold. The preliminary design plan for this essential component is predicated on effectively controlling pressure and heat, maintaining the two at maximum levels to permit the molten material to remain hot for as long as possible to ensure that it is uniformly distributed.

The runner is constructed out of several sectional shapes and branches, all of which work together to ensure that there are no obstacles in the way of the uninterrupted flow of materials from one component to the next.

Circular is one of the most popular shapes used in the design of runners. Its shape gives a minimum area that switches sides after production has begun, allowing both plates to be aligned. Runners also come in other shapes. The rectangle, the trapezoid, the U-shape, and the semicircle are some other shapes utilized.

Usage of Injection Molding Runner:

While using injection molding runners, it is critical to understand their applications in the injection molding process. Now an injection molding runner is commonly used in the following processes:

- Moves molten plastics into the cavity of a mold in the quickest possible time and with the most negligible heat and pressure loss.

- Molten polymers must simultaneously enter a cavity (or cavities) at all gates under the same pressure and temperature.

- Cross-sections should be kept narrow to save material. A large cross-section may be advantageous for optimum cavity filling and adequate holding pressure. A more extensive cross-section, on the other hand, may lengthen the cooling time.

- The surface-to-volume ratio should be kept as low as possible.

Types of Runners Used in Injection Molding – Hot vs. Cold Runner:

Below are the two types of runners commonly used during the injection molding production process:

Hot runner

The hot runner system is a more sophisticated option that gained popularity in the 1980s.

In contrast to a conventional cold runner system, a hot runner system integrates electric heating elements directly into the mold itself. These heating elements work with individual nozzles within the mold to ensure the material is delivered to each cavity at the appropriate pressure and temperature.

A manifold, an inlet, and individually heated nozzles leading to each cavity comprise a hot injection molding runner system. It is possible to exercise fine-grained control over the temperature at which the heated elements operate to preserve the material features of the molten plastic. Several types of hot runner systems come equipped with valve gates that lead to each cavity. This gives the user even more control over how the mold is filled.

Moreover, hot runners offer superior component quality while simultaneously lowering the amount of wasted material (because there is no sprue material to be removed after molding, for example). On the other hand, the price of a mold equipped with a hot runner system is significantly higher than that of a mold equipped with a cool injection molding runner system.

Cold runner

The conventional cold injection molding runner system lacks any heating devices integrated into the mold. Although less complicated, it has tremendous potential for problems like underfilled areas, sink marks, and slower cycle times. In addition, the sprue and channels of the molded parts need to remove any excess material.

Does Runner Design Affect Plastic Parts Production Quality?

Since the injection molding runner serves as a critical channel through which molten materials can enter the cavity, it should be no surprise that the runner’s design affects the product that is ultimately manufactured. The width of the hot runner is the primary aspect of the product’s design that will be responsible for determining the plastic components. If you want to print larger components, you will need to use a larger runner; likewise, if you want to print smaller parts, you will need a larger runner. In addition to this, you need to choose whether you will use a hot runner or a cool injection molding runner to ensure the quality production of your desired product.

Although each performs activities analogous to one another, they are tailored to address distinct facets of the production process. The time commitment and the financial investment are also important aspects to consider.

Tips for Choosing the Ideal Runner Design for Quality Plastic Production:

While building a runner, a few considerations must be given your full attention. You will be able to solve all potential issues and faults that may prevent successful injection molding with the help of these tips. The following are some of these contributing elements.

Have You Figured Out The Appropriate Quantity for the Product That You Would Manufacture?

When designing the mold and selecting the runner, the quantity of the item you intend to produce is one of the most important factors to consider. Consider using a cold runner as an example if your final goal is to make a large quantity of anything.

Is There Enough Time Allotted for The Manufacturing Cycle?

The product’s manufacturing rate is another factor that ought to steer you properly. This is never an issue as most runners are of a respectable speed. If you expand the manufacturing volume using the same sort of runners, you might need some help.

What Kind of Injection Pressure Do You Like to Use?

In conjunction with the crucible’s capacity to retain heat, the injection pressure is crucial in ensuring that the cooling process is consistent and flaws-free. In choosing your choice, you should go for the competitor with the highest injection pressure.

Is the Runner You Picked Simple to Keep Up with and Repair When Necessary?

Because there are so many moveable components, minor mechanical faults may inevitably arise, and the cost can be expensive if the runners in question are very sophisticated. Always choose the type that can be easily maintained and fixed wherever possible.

Conclusion:

All in all, an injection molding runner is used throughout the injection molding process, and it comes in a wide variety of forms. If you’re new to injection molding, choosing which is best for your purposes can be difficult. Hence, it’s always better to consult professional manufacturers to seek insight and ensure the ideal manufacturing of your desired plastic products.