Draft angle is an essential step in the design of every mold. Some engineering drawings may not initially include the draft angle, but that doesn’t mean it’s omitted; it’s simply addressed in a later stage of the process. In mold design, before creating the 3D split of the mold, there are two primary considerations: shrinkage and adjusting the draft angle. When you receive product designs from customers, those with a good understanding of the manufacturing process often provide the necessary draft angles. However, in most cases, the draft angles are not specified. This is when you need to make the necessary modifications.

Why do we need to design Draft angles?

Draft angles play a crucial role in mold design, serving a dual purpose in ensuring the successful production of high-quality products. They are primarily implemented to simplify the extraction of a product from the mold and to prevent various defects, with ejector marks being one of the significant concerns.

First and foremost, draft angles are designed to make the demolding process smoother. When a product is manufactured inside a mold, it forms a close-fitting cavity with the mold’s surfaces. Without a draft angle, the product might get stuck or “hang up” within the mold. This can result in considerable difficulty during removal, potentially causing damage to both the product and the mold itself. Imagine trying to pull a vacuum-sealed jar from a shelf without first loosening the seal; a draft angle essentially provides that initial separation, making it easier to release the product from the mold without distortion or breakage.

Additionally, draft angles are instrumental in preventing defects like ejector marks. Ejector marks are unwanted blemishes or impressions on the surface of the product, typically caused when ejector pins forcefully push the product out of the mold. If there were no draft angle, the product would resist being pushed out, leading to these unsightly marks. By incorporating draft angles, the product can be gently and uniformly released, minimizing the risk of such defects.

In essence, draft angles are like the gentle incline of a slide at a playground. They ensure that the product smoothly slides out of the mold, reducing the chances of damage and defects. Consequently, mold designers carefully calculate and implement the appropriate draft angles to strike a balance between easy demolding and maintaining the product’s structural integrity. This attention to detail in mold design is essential for achieving consistent, high-quality manufacturing results.

The choice of draft angles in mold design

The choice of draft angles in mold design depends on the properties of the plastic, the shape of the product, and the desired surface finish. While there may not be specific industry standards for selecting draft angles, it’s essential to follow these principles in the actual design process:

Reduce Material:

Reduce the material used for draft angles when removing a product from the mold, as draft angles can help reduce material usage by allowing for easier mold release. However, the primary purpose of draft angles is not specifically to reduce material but to ensure smooth demolding.

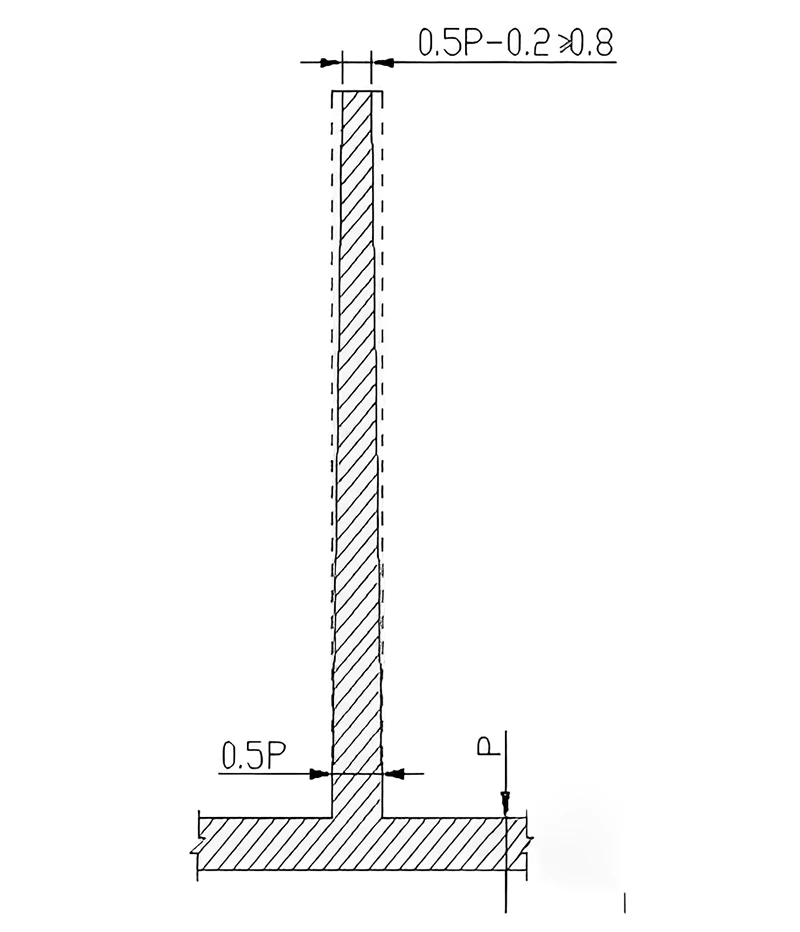

Rib Structures:

For rib structures, the draft angle is typically between 0.25 to 1. But make sure the top dimension is not less than 0.8mm. Still, it should be noted that the specific draft angle may vary depending on factors such as material, rib thickness, and the intended application. The requirement that the top dimension should not be less than 0.8mm is sensible for ensuring structural integrity.

Product Surface Height:

When removing the surface of a product, if its height is less than 40mm, use a draft angle of 1 degree. If it’s greater than 40mm, use a draft angle of 0.5 degrees. However, the optimal draft angle can depend on factors such as material and part geometry.

Textured Products:

The draft angle for textured products should depend on the specified texture, pattern, and depth. In general, for external textured surfaces, add 1 to 1.5 degrees of draft angle for every 0.001-inch depth. Internal textured surfaces may require even greater draft angles. While adding draft angles to textured surfaces is generally necessary, the exact angle required should be determined by testing and considering the specific texture characteristics.

Less Critical Areas:

Increasing draft angles in less critical areas can be a valid approach to simplify manufacturing and demolding. Still, it should be done judiciously to avoid excessive material waste or unintended consequences.

Modifying Draft Angles:

When modifying the product’s draft angles, maintain assembly relationships and appearance requirements. Critical dimensions must be within specified tolerances after demolding. For uncertain aspects, consult with the customer for clarification.

Glossy External Surfaces:

For small products with glossy external surfaces, use draft angles of ≥ 1 degree. For larger products, use draft angles of ≥ 3 degrees.

Kiss-Off or Shut-Off Areas:

The slope for kiss-off or shut-off areas should be as large as possible to prevent interference or friction.

How To Check Draft Angles In UG Software?

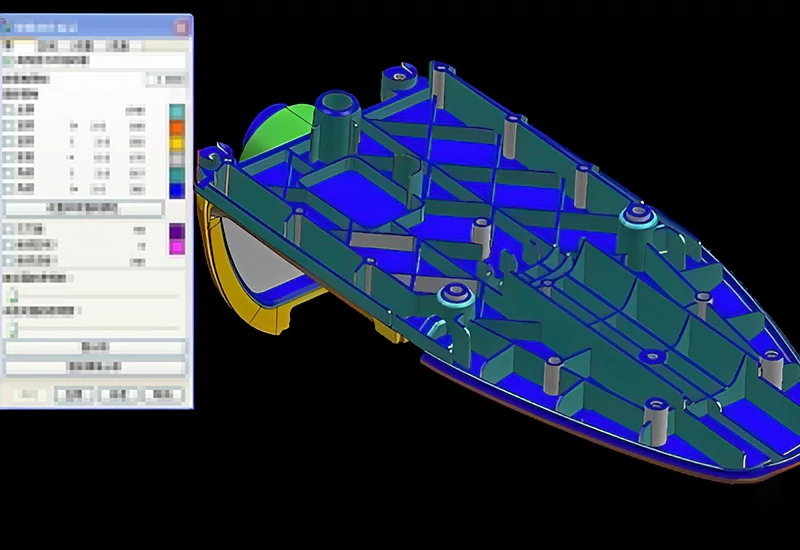

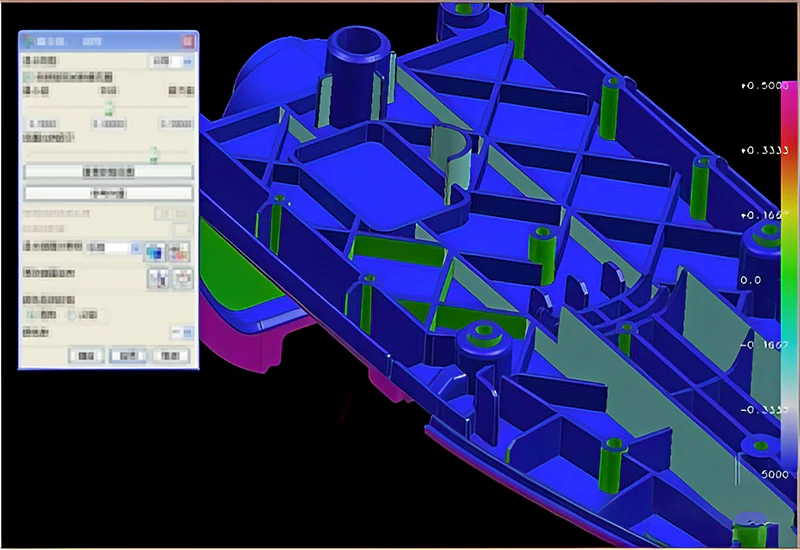

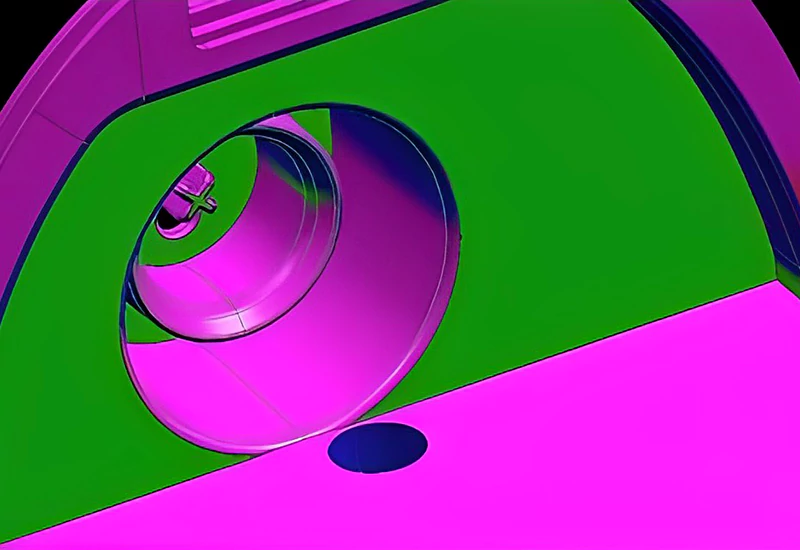

In UG software, there are two common methods for checking draft angles: slope analysis and plastic mold component validation.

Slope Analysis: In slope analysis, you can identify draft angles by analyzing the colors of the faces. Magenta-colored faces represent the positive draft direction. Green faces indicate a 0-degree angle, and blue faces represent the negative draft direction. If you find blue faces within magenta ones, those blue faces are undercuts. Similarly, if you find magenta faces within blue ones, those magenta faces are undercuts as well.

Plastic Mold Component Validation: When analyzing plastic mold components, you can determine positive and negative faces based on the degree values displayed in the options tab. Compared to slope analysis, plastic mold component validation provides a more specialized analysis of the product’s positive, negative, straight, and undercut faces.

Prototool has many years of experience in the field of mold manufacturing. If you have any questions about draft angles or if you need parts or products to be produced, please feel free to contact us at any time.