Are you opting to consider production using acrylic? Of course, but the question ‘can acrylic be injection molded‘ may keep you from making a final decision. But here’s the good news, even though acrylic has a glass-like outlook, it is still more flexible. So with the help of an acrylic injection molding machine, you can easily mold acrylic in whichever shape you require. Now, if you’re curious about how acrylic can be injection molded, here’s a detailed guide to exploring everything about it. Keep reading to learn more!

What is Acrylic Injection Molding?

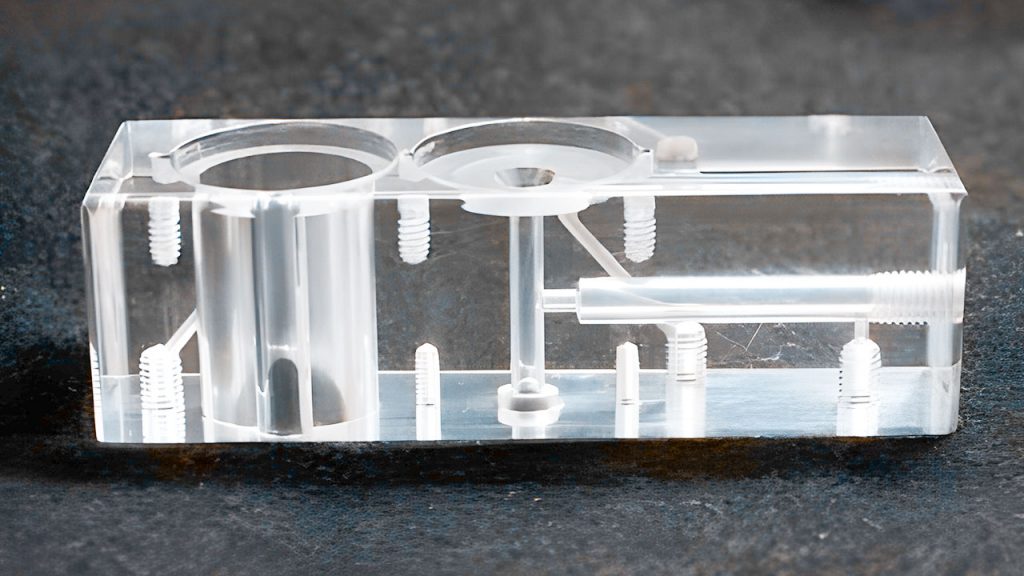

Acrylic injection molding is a flexible technique for creating various objects from acrylic material. However, it’s essential to consider the properties of acrylic, its uses, and how it can be used to make different products – before you consider using it for production needs.

Acrylic is a synthetic plastic sheet containing one or more acrylic acid derivatives. Simply put, it is a form of plastic that comprises glass-like characteristics. You may have seen many crockery items, cookware, and even toys made of such material, which may seem like glass, but it isn’t.

Hence, acrylic is used to construct intricate forms of products since it is easy to mold products to achieve a glass-like outlook. Whereas, if we look at the glass itself, it is too delicate to be molded into complex shapes per various product manufacturing demands. As a result, it makes acrylic more appropriate for usage in many cases by shaping it according to the product.

All these characteristics make using injection molding machines for molding acrylic products in various products more effective. In addition, the final product of the desired shape can be achieved with a simple process of molding acrylics by injecting hot materials into the mold.

PMMA:

PMMA is also known as plexiglass, acrylic, and other similar terms. Polymethyl methacrylate is its chemical name. PMMA modifications have developed one after the other as a result of the shortcomings of PMMA. These disadvantages of PMMA include high surface hardness, easy wiping, low impact resistance, and poor molding fluidity.

Furthermore, PMMA has a lower flow rate than PS and ABS. Its temperature fluctuations also affect melt viscosity. The injection temperature mainly causes the variation in melt viscosity during the molding process. PMMA is an amorphous polymer. This amorphous polymer has a melting point of over 160°C and a decomposition temperature of 270°C.

Considering all these characteristics of PMMA, it is pretty evident that the shortcoming of this type of acrylic makes its usage in various forms of production limited to specific procedures and precautions. It is highly preferable and common to use PMMA to produce different intricate-shaped products in PMMA injection molding.

Following the ideal practices and effective procedures and keeping the properties and characteristics, like temperature fluctuations, etc., with the help of professional service providers like Prototool, managing PMMA injection molding can be easier and more effective.

Advantages Of Acrylic Injection Molding:

Here are a few advantages that make mold acrylic highly demanded in the market:

1. Scratch-Resistance:

According to research, acrylic molding materials are more scratch-resistant than glass. Hence, using an injection molding machine helps produce items that may retain their shiny looks for an extended period without deterioration.

2. Light Products Manufacturing:

The density of acrylic is 1.185 grams per cubic centimeter. The density of glass, on the other hand, is 2.4 grams per cubic centimeter. Considering the densities of both products, it is evident that PMMA injection molding helps produce items that may be utilized as lightweight substitutes for glass.

3. Producing Complex Designs:

Plastic or PMMA injection molding produces sophisticated forms that other injection molding methods, such as metal injection molding, cannot produce. Furthermore, the PMMA injection molding technique can replicate many identical products in shape, size, and weight.

4. Efficient Manufacturing:

PMMA injection molding is a speedier technique than metal injection molding. Therefore, it allows the production of more manufacturing units in a given time frame using the injection molding machine. So you can conduct large-scale and batch manufacturing of acrylic products using acrylic molding without compromising on time schedules or deadlines. Technical evaluations have also revealed that injection molding machines have lower cycle times, increasing the industry’s overall output and production efficiency.

5. High Color Flexibility:

Acrylic injection molding machines can combine injected acrylic with resins to generate a broad range of colorful goods that can be conveyed in a larger market and feed customer demands. However, other methods, such as metal/glass injection molding, do not have this characteristic of color flexibility.

6. Transparent Plastic Manufacturing:

Acrylic, or Plexiglass, is a PMMA material with a transmittance of up to 92%, which is higher than glass, making acrylic molding one of the best solutions for high-requirement precise injection molding components such as glass, optical glass, lenses, vehicle lights, transparent pipes, and so on.

Applications Of Acrylic Injection Molding:

Before we explore how the acrylic molding process is conducted, let’s first talk about the application of injection molding machines and the acrylic products produced by these machines:

Application of Acrylic Injection Molding Machine:

You can use an acrylic injection molding machine in a variety of applications, including:

- Molding various forms of medical gadgets

- Molding various automotive product forms

- Creating various forms of industrial equipment, such as protective eyewear.

- Molding acrylic sheets to produce various structures for the construction sector

- Molding various sorts of domestic appliances such as refrigerator drawers and plastic glasses

Applications of Injection Molded Acrylic

Acrylic is frequently utilized to fulfill product demands for a glass-like quality, fading resistance, and scratch resistance products. Hence, it is commonly used in:

- Skylights

- Lenses

- Food storage containers

- Producing refrigerator components

- Construction materials

- Automotive

- Displays and signs

- As a glass replacement

- Fashion items

- Beauty items

- Electronic items

- Paint

Specifications of Acrylic for Effective PMM Injection Molding:

As a thermoplastic, acrylic can be heated to its melting point, cooled, and then reheated without degrading—the liquefication of acrylic makes it useful for acrylic injection molding machines and recycling. In addition, acrylic is a scratch-resistant material that is substantially lighter than glass. This property of acrylic makes it ideal for projects that demand clarity, precise tolerances, consistency, and intricacy. The significant properties of acrylics that should be considered during PMMA molding include the following:

- Shrink Rate: 0.2-1%

- Melting Point: 266°F

- Injection Mold Temperature: 175-225°F

- Flexural Strength: 13000 psi

- Tensile Strength: 8,000-10,000 psi

PMMA Injection Molding Process:

1. Plastics processing

The very first process is to treat the plastic for processing. PMMA has a water absorption rate of 0.3-0.4%, and PMMA injection molding requires a humidity level of less than 0.1%, generally 0.04%. Here, the presence of water during the melting of acrylic, bubbles, gas lines, and diminished clarity are generated.

So, to avoid that and conduct production efficiently, PMMA must be dried. For this, the drying temperature is 80-90°C, and the drying duration exceeds 3 hours. Yet, in certain situations, recycled materials can be utilized entirely as per their quality standards and without the presence of any pollution the usage of recycled products.

2. Selecting an Acrylic Injection Molding Machine:

Here comes the flexible part – PMMA has no particular injection molding machine requirements. Because of its high melt viscosity, it only necessitates a deeper screw groove and a bigger diameter nozzle hole. If the product has greater strength, a screw with a bigger length-to-diameter ratio should be utilized for low-temperature plasticization. Furthermore, PMMA must be kept in a dry hopper. So as long as an acrylic injection molding machine fulfills these basic requirements, it is ideal for conducting PMMA molding tasks.

3. Design of the Mold and the Gate

The mold temperature can range from 60°C to 80°C, the sprue width should match the inner taper, and the optimal angle is 5° to 7°. If you wish to inject items 4mm or larger, the angle should be 7°, the sprue diameter should be 8 to 10mm, and the total length of the gate should not exceed 50mm. Furthermore, the diameter of the runner should be 6-8mm for goods with a wall thickness of less than 4mm.

For goods with walls thicker than 4mm, the runner diameter should be 8-12mm diagonal, the fan-shaped and tabular gate depth should be 0.7 to 0.9t (t being the product wall thickness), and the needle gate diameter should be 0.8 to 2mm. to achieve lower viscosity, it is preferable to use smaller sizes of acrylic.

4. Proceeding with Melting Temperature

The melting temperature for acrylic molding can be measured using the air injection method. In the air injection method, the temperatures should range from 210°C to 270°C, depending on the information supplied by the source. To conduct this process, you need the withdraw the rear seat, let the injection molding machine’s nozzle escape the sprue bushing, and then manually execute plasticization or air injection molding.

5. Temperature of Injection

In this process, you can employ fast injection. However, it is essential to prevent significant internal stress and multi-stage injection, such as slow-fast-slow. Furthermore, if you’re inserting the injection in thick sections, slow down on the speed.

6. Detention period

Last but not least, it’s time to handle the acrylic molding detention. In this phase, if the temperature is 260°C, the residence period should not be more than 10 minutes. Whereas, if the temperature is 270°C, the residence time should be less than 8 minutes.

Conclusion:

So that’s all to our detailed guide on PMMA molding. We hope it answers all your questions regarding whether acrylic can be injection molded or not.

For more queries and details, don’t hesitate to contact our professionals.