The term “manufacturing” is most commonly linked with large-scale manufacturing plants and assemblies with complicated machines continuously churning out various goods. While this manufacturing approach is common and traditional, a rapidly growing manufacturing model is gaining popularity as it solves several of the limitations inherent in traditional manufacturing. This is referred to as on-demand manufacturing.

What Exactly is “On-Demand Manufacturing”?

On-demand manufacturing, also known as custom manufacturing or cloud manufacturing, is a manufacturing system in which things are only made when needed and in the quantities required. This new technique differs from traditional manufacturing, in which things are mass-produced and held in facilities until they are sold, distributed, and delivered. Factors that promote the expansion of on-demand manufacturing.

What is Influencing the Growth of On-Demand Manufacturing?

We live in a fast-paced society where the bulk of our requirements, such as food, housing, transportation, and so on, can be met on-demand thanks to IT and logistical infrastructure advancements. As a result, the transition from traditional manufacturing to the on-demand model is entirely natural. Some certain factors that have contributed to this transition include:

· Equipment Used in Contemporary Manufacture

In the early days of manufacturing, methods such as the production process, including an assembly line, were used. During this time, there was no room for customized manufacturing or production batches with a low volume. However, contemporary manufacturing technology such as computer numerically controlled (CNC) machining and three-dimensional printing has fundamentally altered our conception of what is feasible. Not only are they able to create production runs with low volumes, but they are also able to fulfill any specifications for bespoke manufacturing.

· Industry 4.0:

The development of Industry 4.0 has also contributed to the advancement of the idea of “manufacturing on demand.” Companies are transitioning to a new model due to the availability of solutions such as cloud-based technology. This new model allows historically in-house teams to interact digitally, making generating and implementing improvements easier.

· Logistics:

The rise of the e-commerce industry has resulted in a profound transformation of the logistics network on a global scale and inside the boundaries of individual nations. The size of items that can be transported is not restricted in any way, and the rates at which they can be moved have multiplied by many orders of magnitude. As a result, consumers can obtain their orders on a fixed time schedule whenever necessary, which eliminates the requirement for mass production.

· Digital Manufacturing

Through the utilization of digital manufacturing processes, manufacturers can detect and remove any bottlenecks and problems that may arise. They can also increase the quality of the product and include adjustments that the customers require. As a result, operating a manufacturing process based on consumer demand ultimately improves both the production rate and the experience provided to customers.

The Advantages Of On-Demand Manufacturing

Such type of manufacturing has several advantages over traditional production.

Manufacturing on demand has various advantages over traditional manufacturing. These benefits benefit a variety of groups, including manufacturers, customers, end users, and others. Some of the benefits are discussed below.

· Low Production Volumes and Customization:

End-user requirements vary greatly, as do their desires and personal preferences. On-demand manufacturing enables producers to supply what consumers desire regarding quantity and manufacturing specifications.

On the other hand, the typical production strategy makes it nearly impossible for a consumer to request a personalized product. It is because the hardware arrangement in traditional manufacturing plants is fixed, and any significant change would be prohibitively expensive. Furthermore, employing a standard manufacturing setup to produce a limited volume of products would be extremely inefficient.

In contrast, with this manufacturing, a customer can order a single prototype, no matter how complex, and have it manufactured and delivered quickly. Custom manufacturing is critical in many areas, including the medical field.

· Reduced Storage and Logistics Costs for Manufacturers:

Traditional manufacturing entails intricate logistics procedures. After bulk-producing a product, the company must have a sophisticated and insured storage/inventory system. This is in addition to a robust sales network for marketing and distribution of the products. In addition, the manufacturer must provide, manage, and maintain transportation/logistics infrastructure. All of this contributes to exponentially rising manufacturing costs.

Manufacturing on demand significantly reduces logistical costs by eliminating the need for premade product storage, insurance, marketing, and delivery. Bulk production in traditional manufacturing, one could claim, saves money due to economies of scale. However, because the on-demand concept is highly adaptable, it can accommodate both one-off manufacturing and production runs of thousands.

· More Usage of Small and Medium-Sized Technologies

The cost of establishing a traditional manufacturing plant is enormous due to the massive number of products typically created, with single machinery costing millions of euros. On the other hand, manufacturing-on-demand systems may handle tiny volumes cost-effectively by utilizing significantly less expensive equipment. This enables small and medium-sized businesses to establish small-scale manufacturing facilities.

· More Product Control and Less Waste:

An estimate of consumer demand defines the volume of things manufactured in conventional manufacturing. This estimate is prone to inaccuracies, raising the prospect of supply exceeding demand. Products in storage are also vulnerable to damage, seasonal dips in demand, and unforeseeable events. For example, during the 2020 coronavirus pandemic, enforced global lockdowns left some firms stranded with their products. Such circumstances result in losses and waste, which may pose a threat to the environment. In the manufacturing on-demand paradigm, supply can never exceed demand because supply is always created on demand.

This manufacturing approach also saves a lot of resources that would otherwise be needed to manufacture products that may never be used. Manufacturers can be confident that they will sell 100% of any product produced because they can only produce things that they have already sold.

· Increases inventiveness

Custom manufacturing’s regular connection between customer and manufacturer, short lead times, flexibility, low cost, and operational transparency have substantially increased the rate of technical innovation. Innovators and innovators can design goods and have a single prototype made in record time and at a low cost. The prototype can then be utilized to fine-tune the product, resulting in a short time to market.

The combination of CAD and on-demand manufacturing has significantly expanded the number of wonderful items that enter the market daily. Check out our customer’s story, who quickly developed a device to combat the COVID pandemic. Only giant firms could previously afford the costs of researching, creating, prototyping, testing, and producing a new product. Today, almost anyone with a good concept can make it a reality.

Technologies Used in This Manufacturing Approach:

There are numerous technologies available for use in an on-demand manufacturing system. These are some of the technologies:

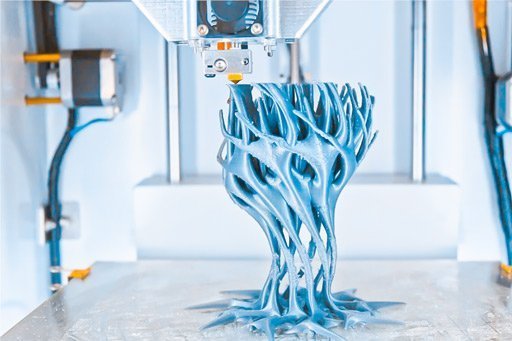

Ø Three-Dimensional Printing

For small production runs, such as prototyping, 3D printing has become one of the most common manufacturing technologies. The procedure is relatively inexpensive, although it compromises precision to some extent. It is essential to highlight that 3D-printed objects can only be made of plastic-forming materials.

Ø Stereolithography (SLA) (SLA)

Stereolithography (SLA) is a 3D printing method subtype. It is also known as resin printing, optical manufacturing, and vat photopolymerization. It makes use of a high-powered laser ray that is focused on a photopolymer resin. The CAD files define the ray’s movement. Layer by layer, the liquid resin hardens and hardens into the final part.

Ø Modeling of Fused Deposition (FDM)

Fused Filament Fabrication (FDF) is another name for Fused Deposition Modeling (FDM) (FFF). This approach is a subset of 3D printing. It employs a wire filament that is fed through a spool to the printing head, where it is melted and molded into the required item as the head moves in tandem with the computer.

Ø Laser Sintering with Preference (SLS)

SLS is a sort of additive manufacturing technology in which a laser sinters a powder made of nylon or polyamide to solidify it into the required shape. A computer, similar to a 3D printing machine, controls the laser movement. This method is only used for low-volume manufacturing and quick prototyping.

Direct Metal Laser Sintering (DMLS) DLMS is extremely similar to SLS, with the exception that DLMS creates the product using metal powder. This method is typically used to make tough, high-performance components that cannot be made from polymers such as nylon or polyamide.

Ø CNC Manufacturing

CNC machining has been around for a while. The advancement of such manufacturing has effectively utilized the benefits of CNC machining. It is suitable for practically all materials and gives unrivaled precision. There are numerous varieties of CNC machines, each with its unique purpose and design requirements.

Ø Molding via Injection

Injection molding is another prominent manufacturing technique that can be utilized on a local or large scale. A plastic-based resin is injected into a mold to manufacture the required part shape. It is also a low-cost production process with limited precision.

Ø Forming Sheet Metal

Sheet metal forming is the process of transforming a flat metal sheet into the desired item. The shape of the part is obtained by deforming the metal sheets using various methods. While it appears to be a simple procedure, it is highly costly. Some innovative Incremental Sheet Forming Technologies, on the other hand, can help to reduce costs while retaining good quality.

Conclusion:

While traditional manufacturing is the major manufacturing paradigm today, on-demand manufacturing is fast transforming the sector, accelerating the rate of innovation, and making manufacturing accessible to individuals and organizations alike. Given this, it is never too late to choose on-demand manufacturing services and experience their benefits and features for yourself with experienced service providers such as First Part.

Contact our experts today for additional information and questions.