Mold fabrication is a critical process in the manufacturing industry, and it involves the creation of molds or dies that you use to produce a wide range of products. While mold fabricating is essential for making high-quality products, it can be a challenging skill to learn.

So are you a beginner or intermediate professional in the manufacturing industry planning to expand your skillset? Do you want to strengthen your mold fabrication skills and create a more robust professional career for yourself? Then you’re at the right post.

This article will discuss why mold fabrication is so hard to learn and provide tips for improving your mold fabricating skills. Read on if you aim to explore and polish your skills in mold fabricating.

What is Mold Fabrication?

As a technical and detailed process, mold fabricating typically involves using specialized software tools and equipment to produce a three-dimensional model of the mold or die, machining from a solid block of material using precision machining techniques.

The materials used to create molds and dies can vary, depending on the product’s specific requirements, but typically include metals such as steel or aluminum, as well as plastics and other composite materials. Mold fabrication requires a high degree of technical expertise and precision, as even minor errors or defects in the mold can result in defects in the finished product.

Additionally, quality control is an essential aspect of mold fabricating, and molds are typically tested and evaluated for defects using various techniques, including visual inspection, dimensional analysis, and testing for material integrity. Overall, mold fabricating is a critical process in the manufacturing industry, and it plays a vital role in enabling the production of high-quality products at scale.

The Industries That Require Mold Fabrication for Their Product’s Manufacturing:

Mold fabrication is common across various industries, including automotive, aerospace, consumer goods, medical devices, etc. Here are some examples of how mold fabricating is essential for the production of parts used in different industries:

Automotive industry

Mold fabricating is a crucial process in the automotive industry, producing various car parts, such as engine components, steering systems, suspension components, and body panels. The molds used in this industry are typically large and complex, requiring high precision and accuracy.

Aerospace Industry

Mold fabricating is used in the aerospace industry to produce components such as turbine blades, engine parts, and other complex features. The molds used in this industry must be able to withstand high temperatures and pressures, and they must be able to produce parts that meet strict safety and performance standards.

Consumer Goods Industry

Mold fabricating produces consumer goods such as toys, household appliances, and electronics. The molds used in this industry can vary in size and complexity, depending on the product produced.

Medical Devices Industry

Mold fabricating produces medical devices such as prosthetics, implants, and surgical instruments. It’s essential to make the molds used in this industry from biocompatible materials and meet strict regulatory requirements.

Packaging Industry

Packaging materials such as bottles, containers, and lids are produced through mold fabrication. The molds in this industry are commonly crafted from plastic or metal and must manufacture components with accurate measurements and characteristics.

Overall, mold fabricating is critical in various industries to produce high-quality components and products. Its versatility and adaptability make it an essential part of modern manufacturing processes.

Importance of Mold Fabrication

Mold fabrication is crucial in injection molding; you cannot overlook its importance. Some common reasons why mold fabricating is so vital in the injection molding process include the following:

Quality of the Finished Product

The caliber of the mold implemented in injection molding directly affects the excellence of the end product. A meticulously crafted and accurately engineered mold can manufacture components with uniform dimensions, surface texture, and overall superiority.

Efficiency and Cost-Effectiveness

Injection molding is a highly efficient and cost-effective manufacturing process that relies on high-quality molds. A poorly designed or fabricated mold can increase production time, wasted materials, and additional costs.

Flexibility

The injection molding production process offers considerable flexibility; however, this adaptability is contingent upon the mold’s versatility and quality. A precisely fabricated and skillfully designed mold can create an assortment of parts with diverse shapes, sizes, and complexities.

Adaptability

As product designs and specifications change over time, the mold used in injection molding must be adaptable and able to accommodate these changes. A well-designed and fabricated mold can be modified or repaired to adapt product design or manufacturing changes.

Regulatory Compliance

Many industries, such as medical devices and aerospace, have strict regulatory requirements that you must meet in the manufacturing process. A well-designed and fabricated mold ensures the finished product meets these regulatory requirements.

Competitive Advantage

The quality and efficiency of the injection molding process can provide a competitive advantage in the marketplace. A company that can produce high-quality parts quickly and cost-effectively can gain a significant advantage over its competitors.

Who Manages Mold Fabrication and How?

A team of skilled professionals, including designers, engineers, machinists, and quality control specialists, work on managing this process. These individuals work together to design, create, and test molds that meet the product’s specific requirements. Overall, during mold fabrication, every team member contributes a distinct set of skills and expertise to the procedure, and cooperation is crucial in ensuring the project’s triumph.

Now there’s no denying that mold fabricating is a highly technical process that requires a combination of design, engineering, and manufacturing skills. Once you understand who and when manages each task of mold fabrication, it’s important to understand the tasks involved in this technical process. It includes:

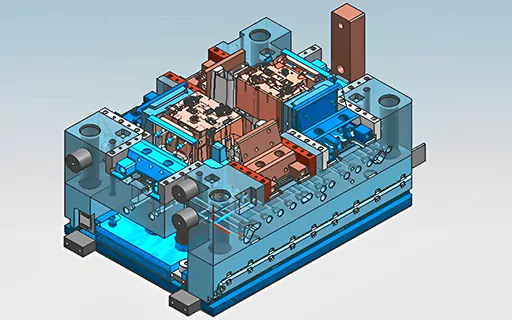

Mold Design:

The first step in mold fabrication is mold design. This process involves creating a detailed 3D model of the mold, which considers the desired product shape, size, and features. Professionals typically use CAD software to create the 3D model of the mold, and the design must consider factors such as material properties, injection pressure, and cooling time.

Material Selection:

The next step is selecting the mold’s appropriate material. The material must withstand the high pressure and temperature of the injection molding process while maintaining its dimensional stability. Common materials used for molds include steel, aluminum, and other alloys.

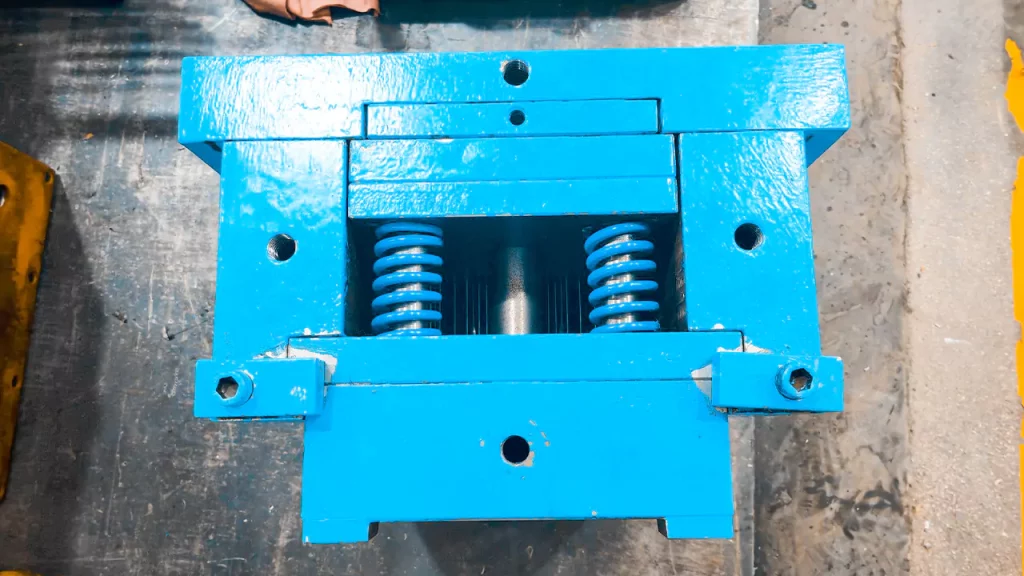

Mold Machining:

The mold can be machined once the mold design and material selection are complete. This process involves using specialized pieces of machinery, such as CNC machines and lathes, to cut and shape the mold according to the 3D model. The mold must be machined to a high degree of accuracy and precision to ensure that the finished product meets the desired specifications.

Heat Treatment:

After mold machining, it undergoes a heat treatment. This process involves subjecting the mold to high temperatures to improve its strength and durability. The heat treatment process may include quenching, annealing, or other heat treatment techniques, depending on the material used and the desired properties of the mold.

Polishing and Finishing:

Once the mold has been heat-treated, it is polished to improve its surface finish and remove any burrs or imperfections. This process involves using specialized equipment, such as polishing wheels and sandblasting equipment, to achieve the desired surface finish.

Mold Testing:

Before you use the mold in production, it must undergo testing to ensure it meets the desired specifications. Testing typically involves injecting a small amount of material into the mold and examining the finished product for defects or inconsistencies.

Mold Maintenance and Repair

After you use the mold in production, it must be adequately maintained and repaired to ensure its longevity and reliability. This may involve routine cleaning, lubrication, and more extensive repairs if the mold becomes damaged or worn.

Why is Mold Fabrication So Hard to Learn?

There are several reasons why mold fabrication can be a challenging skill to learn, including reasons like:

- The process is highly technical and requires a deep understanding of the materials

- Machining techniques and quality control standards

- The equipment used in mold fabricating is often specialized and requires extensive training to operate properly

- And also because mold fabricating requires a high degree of precision, and even minor errors can result in significant defects in the finished product.

5 Tips to Improve Your Mold Fabricating Skills:

Below are several steps you can take to improve your skills. Here are a few tips:

1. Learn the basics of materials science: Understanding the properties of different materials is essential to mold fabricating. Take the time to learn about the strengths and weaknesses of various metals and alloys and the properties of plastics and other materials commonly used in mold fabrication.

2. Take courses in CAD and CAM software: CAD (Computer-aided design) and CAM (Computer-Aided Manufacturing) software are critical tools in mold fabricating. By taking courses in these programs, you can learn how to design and machine molds with high precision.

3. Get hands-on experience: There is no substitute for hands-on experience in mold fabricating. Seek opportunities to work in a fabrication shop or take an apprenticeship with a skilled mold fabricator.

4. Study quality control standards: Quality control is essential in mold fabrication, and understanding the various standards and regulations that apply to your industry is critical. Take the time to study quality control practices and learn how to test and evaluate molds for defects.

5. Practice, practice, practice: Like any skill, learning mold fabricating takes time and practice to master. Be patient with yourself, seek out feedback and guidance from more experienced fabricators, and continue to refine your techniques and processes over time.

Conclusion

Mold fabrication is a critical process in the manufacturing industry, requiring high skill, precision, and technical expertise. While learning mold fabricating can be challenging, it is also advantageous, and mastering this skill can lead to a fulfilling career in manufacturing. So if that’s what you need, follow the tips mentioned above, and you’ll surely get there!