Recently, the demand for strong, low-friction, and wear-resistant materials has surged, aiming to replace metals. Thanks to technological advancements – machined Delrin, a lightweight polymer – has become a versatile choice in various industries. It’s cost-effective and easy to machine, making it a preferred choice. Now, if you plan to make the most of the benefits of machining Delrin (machining POM), this article will help you explore all the do’s and don’ts of POM machining. To get a clearer insight into the professional machining process, we suggest you also go through our detailed guide on machining parts.

Now, without further ado, let’s dive into the details.

POM Grades for Machining

POM’s versatility shines through in its various grades, each tailored to specific requirements. You can refer to the table below to explore more about the POM grades and the different CNC machining requirements they fulfill:

| Grades | Usage |

| PTFE-Filled Acetals | Ideal when impact strength and wear resistance are paramount, PTFE-filled Delrin excels in demanding applications. |

| Glass-Reinforced Acetals | Glass-reinforced Delrin offers enhanced strength and heat resistance, surpassing other grades. |

| FDA-Compliant Acetals | FDA-compliant Delrin grades cater to medical and food-related applications, ensuring safety and quality. |

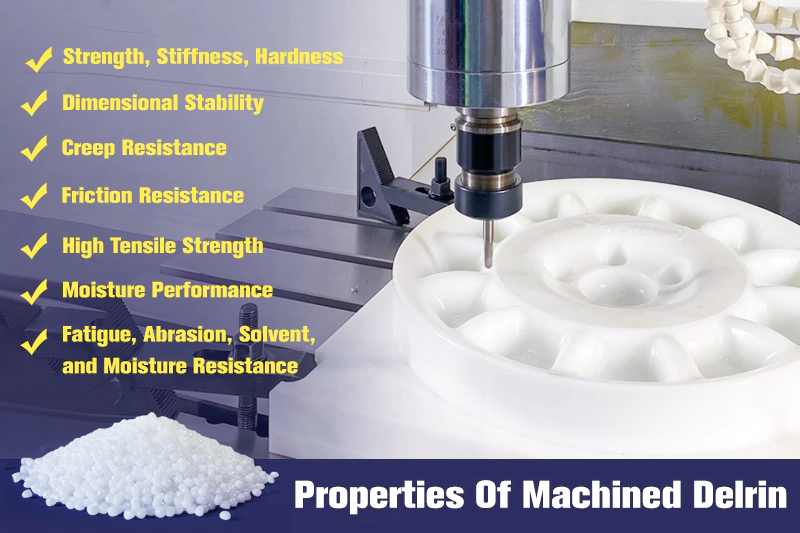

Properties of Machined Delrin

Delrin, an acetal homopolymer, boasts remarkable characteristics that make it a top choice for machining. Here’s a breakdown of its key properties:

- Strength, Stiffness, and Hardness: POM is renowned for its strength, stiffness, and hardness. It provides a solid foundation for various applications that demand structural integrity and durability.

- Dimensional Stability: Delrin exhibits exceptional dimensional stability, ensuring that machined components maintain their intended shape and size over time.

- Creep Resistance: It offers good creep resistance, making it reliable for prolonged stress or load applications.

- Friction Resistance: POM stands out with superior friction resistance, reducing wear and tear in mechanical components.

- High Tensile Strength: With high tensile strength, Delrin can withstand significant forces without deformation.

- Fatigue, Abrasion, Solvent, and Moisture Resistance: Delrin’s resistance to fatigue, abrasion, solvents, and moisture makes it suitable for various challenging environments.

- Moisture Performance: Delrin excels in wet conditions, outperforming materials like Nylon. It retains its low coefficient of friction and wear resistance even in high-moisture or submerged settings.

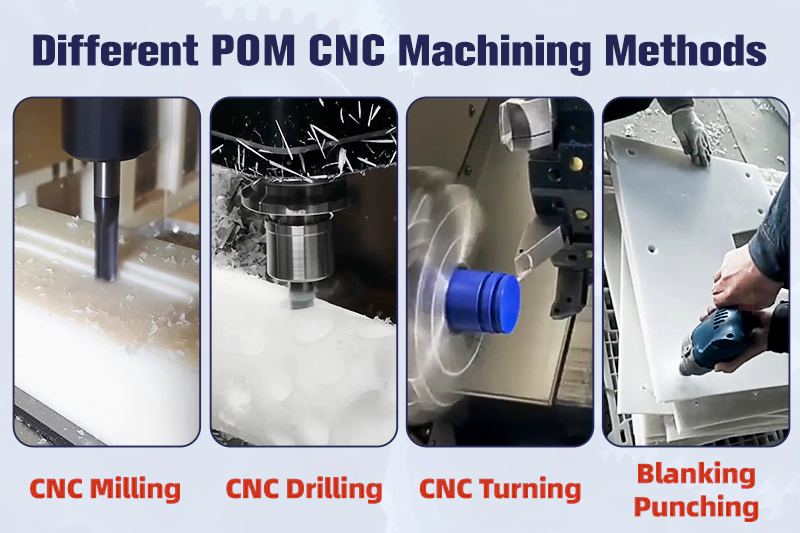

Different POM CNC Machining Methods

Because of their high machinability, POM workpieces can be manipulated into the desired shape using CNC machining operations, such as milling, turning, routing, and drilling (Check POM CNC drilling process).

Delrin can be machined with hard-steel tools, similar to aluminum and copper. It produces the best machining quality with a low feed rate and high cutting speed. In addition, coolants are necessary while machining at a high cutting speed of 250 ft/min.

Delrin CNC Milling

Milling is the most common way to use a CNC machine to shape Delrin into various forms. For Delrin CNC milling, it is recommended to use sharp cutting edges to facilitate continuous chip formations. Delrin milling requires single-fluted mills to prevent heat formation and low chip clearance.

Delrin CNC Drilling

The drilling of Delrin can withstand the standard twist drill. Ground-flat leading edges of drills are the ideal choice when drilling POM, which can be altered by changing lip angles. The perfect scenario is a cutting speed of 1500 rpm, 118° twist drill, medium feed, and no coolant.

Delrin CNC Turning

Turning of Delrin material is quite similar to brass turning operation. It demands high speed and medium feed rate grounded tool bits for smooth operation. A chip breaker can be beneficial in preventing large chip formation, which will also restrict drag and interference.

Blanking & Punching

For the small size parts, blanking & shaping of Delrin sheets is the perfect option for precision POM machining. It can be punched with a hand or a high-pitched punching press. The sheet cracking is a significant problem in punching or blanking the Delrin sheet, which can be solved by pre-heating the sheet.

POM Machining Limitations and Best Practices

POM plastic machining offers impressive versatility and strength, but like any material, it has unique limitations and considerations. Whether delving into Delrin CNC machining or exploring custom Delrin machining, understanding the strengths and the challenges is paramount to achieving exceptional results.

Navigating Delrin’s Limitations

- Adhesion Challenges: Delrin boasts remarkable chemical resistance, a valuable trait in many applications. However, this resistance can pose challenges when it comes to adhesion. Delrin doesn’t readily bond with adhesives, although it tends to be more adhesive-friendly than POM copolymers. When embarking on POM plastic fabrication or POM CNC milling projects, achieving strong adhesive bonds may require specialized techniques or adhesives.

- Flammability Concerns: Delrin doesn’t extinguish itself; it will keep burning until oxygen is depleted. In a Delrin-involved fire, you must have a Class A fire extinguisher ready to quell the flames effectively. It’s crucial to take this flammability aspect seriously, especially when considering Delrin for specific applications.

- Heat Sensitivity: Delrin’s high-temperature sensitivity is a notable concern during machining. Excessive heat can lead to deformation, potentially compromising your project. To mitigate this risk, maintain proper machining temperatures throughout your Delrin machining process.

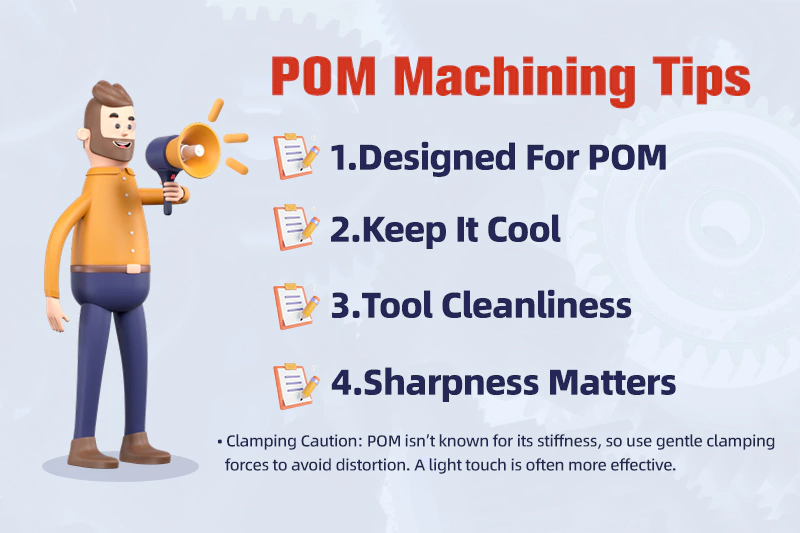

POM Machining Tips

- Designed For POM: When designing components for Delrin machining, strive for consistent wall thickness to ensure precision Delrin machining. Incorporate fillets and ribs as needed, especially for larger parts that may be more susceptible to warping.

- Keep It Cool: Delrin’s high-temperature sensitivity means you should take extra care with cooling during machining. Air-based coolants perform better than liquid options and can help expedite chip removal.

- Tool Cleanliness: To prevent contamination, opt for cutting tools that have never been used to machine aluminum or other metals previously.

- Sharpness Matters: When machining Delrin, a sharp cutting tool with a generous clearance angle will yield superior results. Using cutting lubricants can also enhance the machining process.

- Clamping Caution: POM isn’t known for its stiffness, so use gentle clamping forces to avoid distortion. A light touch is often more effective.

Surface Finishes for Machined Delrin (POM) Parts

Regarding POM plastic machining, achieving the right surface finish is pivotal to meeting your project’s requirements.

Whether you opt for the rugged texture of an as-machined finish or the polished perfection of bead blasting, understanding these choices empowers you to make informed decisions for your next project of POM prototyping, manufacturing of Delrin machined parts, or any other Delrin CNC machining requirement.

Let’s go ahead and explore the different finishing methods for CNC-machined Delrin parts:

As-Machined Finish

An as-machined finish leaves your Delrin part with a surface that retains the marks and texture resulting from the machining process.

This finish is suitable for components where a slightly rough or textured surface is advantageous. It enhances friction, making it ideal for parts engaged in mechanical applications that require grip and durability. If your component will face demanding conditions with intense friction, the as-machined finish can withstand the challenge.

Bead Blast Finish

Bead blasting offers a uniform and consistent surface finish. It eliminates machining marks, leaving your POM part with a smooth and polished look.

This finish is versatile and can be applied to various Delrin parts. It not only enhances aesthetics but also improves durability. Bead blasting is particularly useful for hiding any defects that may have occurred during the machining process.

Whether you’re crafting components for aesthetic appeal or functional excellence, the bead blast finish accommodates a wide range of Delrin manufacturing requirements.

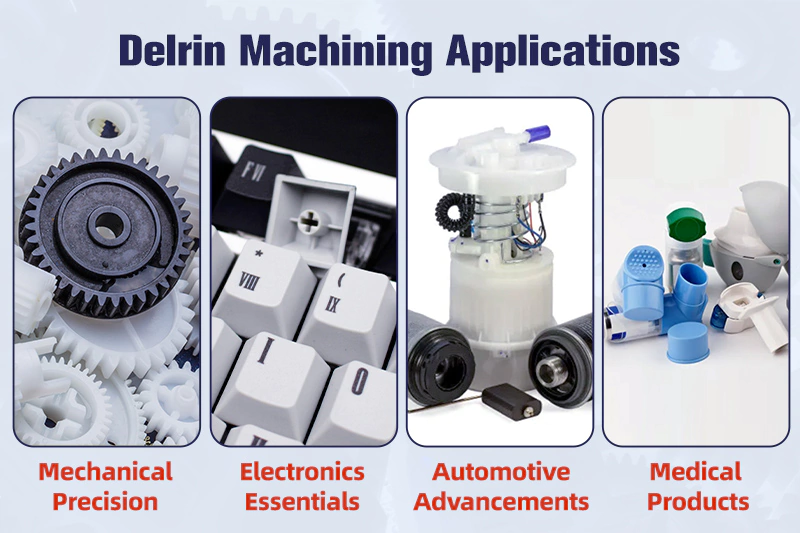

Delrin Machining Applications

Delrin plastic machining has entered numerous industries, from automotive manufacturing to consumer electronics. Understanding the diverse applications of POM is crucial for those engaged in precision Delrin machining, Delrin CNC machining, or any facet of Delrin plastic fabrication.

Mechanical Precision

Delrin’s exceptional properties make it an ideal choice for crafting mechanical components. These may include gears, housings, springs, fan wheels, valves, bearings, rollers, and scrapers. Whether you’re designing robust industrial machinery or intricate mechanisms, Delrin can offer the precision and durability you need.

Electronics Essentials

In the realm of electronics, Delrin shines as well. It serves admirably as an insulator, safeguarding delicate circuitry from interference and damage. Additionally, POM is a top pick for crafting connectors, spools, and various consumer electronic parts, including keyboard covers. Its electrical insulation properties make it a trusted choice.

Automotive Advancements

The automotive industry relies on Delrin for a range of components. From the door lock system to hinged housings and fuel transmitter units, Delrin plays a pivotal role in enhancing automotive functionality and safety. Because of its ability to bounce back and withstand wear and tear, it’s often the first choice for important uses like these.

Medical Products

In the medical field, POM demonstrates its versatility once more. It finds a home in inhalers, insulin pens, and various medical instruments. POM’s biocompatibility and machinability shine through, whether it’s ensuring precise drug delivery or crafting intricate surgical tools like surgical staplers and even guitar picks.

Conclusion

With its unique qualities and wide range of grades, machining Delrin opens up a world of possibilities. Whether you need POM CNC machining or custom Delrin machining for your specific application, this material has you covered.

For expert craftsmanship and top-notch quality, Prototool is a trusted name in the manufacturing industry, always ready to meet your Delrin manufacturing needs. With Prototool, your Delrin projects are in capable hands, ensuring excellence from start to finish.