The machining quality and efficiency of the threads will directly impact the machining quality of the parts and, consequently, the machining center’s production efficiency with the advancement of CNC machining performance. Therefore the advancement of cutting tools and threading methods is continually increasing, and threading accuracy and efficiency are steadily improving. Several thread processing methods typically used in CNC machining centers in practice are summarized in this detailed blog on CNC thread machining.

So if you’re a technologist struggling to choose a thread processing method in processing, optimize production efficiency, and reduce quality accidents, then we’ve got you covered. Keep reading to learn all about CNC thread machining.

Also Read: The Molding Company Fulfilling All Production Needs: Prototool

What is CNC Thread Machining?

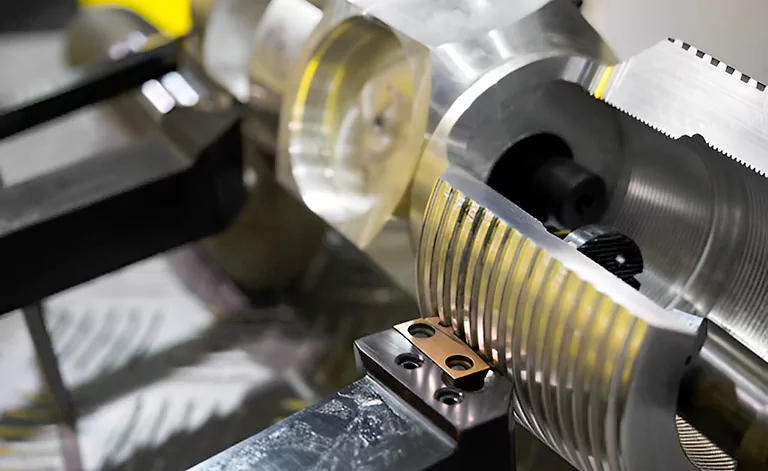

CNC Thread machining is a critical application in a CNC machining center. It is a subtractive approach for creating various diameters of external and internal threads. The circular movement of a rotating tool calibrated with the desired thread depth and density is used for this machining.

A thread’s principal job is to act as a coupling agent between two systems. Motion between pieces happens during the coupling process. Furthermore, a CNC thread machining structure is made up of various pieces. The crest, root, Helix angle, pitch, and flank are examples.

Different Types of Machining Threads:

Various classification schemes exist to categorize threads, resulting in a wide array of distinct thread types.

The UNF (fine) and UNC (coarse) threads are standard options inside the Unified thread system. External and internal threads, on the other hand, are the two most common forms of threads.

External Threads:

This kind of thread is sometimes referred to as a screw thread, and it can be found in things like screws, bolts, studs, and plug gages. Crafting external threads on a lathe is a highly efficient method for producing such threaded components.

The external thread can also be cut by hand using a round die, yet another method. The circular die utilized in this scenario is kept in a die stock that is not mobile. In addition to circular dies, there are hexagonal square dies, which are well-suited for interlocking applications.

Internal Threads:

A single-lip threading tool is utilized in machining an internal thread, also called a female thread. A conventional threading cap and this tool with a single lip might also help cut CNC internal threading.

One must remember that the formation of internal threads by cutting can only occur on concave surfaces.

When exactly is it necessary to use an internal thread? If your workpiece required screw insertions, you would need to have one. When cutting internal threads, machinists utilize either hand taps or machine taps on their machines.

3 Things to Consider for Effective CNC Thread Machining:

Before choosing the optimal threading procedure for a CNC thread machining operation, it is crucial to have a better understanding of your requirements.

Type of the Thread:

When selecting a suitable threading cycle, companies should thoroughly understand the requirements associated with the type of thread.

Even though the G76 cycle is one of the most compact and simple to operate cycles, it does not offer the possibility of cutting unique threads.

For enhanced control over the threading process, utilizing a G32 or G33 threading cycle is highly recommended when working with these types of threads.

Infeed Method of Operation

When using a CNC machine to cut threads, the tool’s movement when sinking in the workpiece to cut the tread is called the infeed.

Radial, modified flank, and incremental infeed are the three primary categories of infeed movements.

Modified Flank Infeed:

Radial infeed is the most common type. The cutting tool is inserted into the workpiece at an angle in the modified flank infeed method. This allows for more precise cutting.

This speeds up the cutting force throughout the full side of the cutting tool, eliminating stress concentration and enhancing the tool’s life span.

In addition, an improved flank infeed facilitates better chip formation and reduces the heat generated during the cutting operation.

As a result, modified flank infeed is one of the cutting methods utilized most frequently in CNC thread machining operations.

Incremental Infeed:

The cutting tool is moved in an oscillating motion from side to side during incremental infeed, known as the incremental infeed technique.

This method feeds the cutting tool at the proper angle while rapidly moving to and fro to cut the required thread. Additionally, the cutting tool is moved rapidly back and forth.

This procedure raises the level of vibration experienced by the cutting tool, which causes chatter to occur along the threaded surface. Nevertheless, the infeed method is best suited for cutting threads with a large pitch.

Radial Infeed:

The cutter is radially plunged into the workpiece during this form of infeed, known as a radial infeed.

This indicates that the cutter penetrates the surface of the workpiece at an angle of zero degrees and continues to move gradually until it reaches the appropriate level of depth.

The cutting force that must be applied to the material to remove it is increased, and tool wear is accelerated. However, this infeed approach is the easiest to execute.

Aside from that, the threads created due to this method have a very small helix angle, making them difficult to engage when fastening.

Cutting Tool:

The kind of cutting tool that you will employ is another component that will determine the success or failure of your thread-cutting operation. Cutting and shaping are often synonymous when referring to the threading operation.

The material can be effectively removed by smoothly maneuvering the cutting tool through the workpiece while simultaneously shaping the threads into the desired form.

For this reason, choosing the appropriate threading tool is essential before cutting the threads on your object.

Also Read: CNC Prototype Machining: What Are The Types and Applications

The type of cycle utilized should also be considered while selecting the appropriate cutting tool.

For instance, the G76 threading cycle only supports insert angles of 0 degrees, 29 degrees, 30 degrees, 55 degrees, 60 degrees, and 80 degrees. Therefore, it is unsuitable for CNC thread machining since it requires a specialized cutting insert.

What is Tap Processing?

To treat threaded holes, the most common approach is to use taps, also known as threading tools. It is mostly useful for threaded holes with minimal hole location precision requirements and small diameters (D30).

In the 1980s, all threaded holes began using flexible tapping methods. This meant that flexible tapping chucks were employed to hold the taps. Tapping chucks offer the potential to compensate axially for the difference arising from the asynchronous feed of the machine tool and the spindle speed. This allows for greater precision in the threading process.

Display the mistake to ensure that the right pitch was used. The flexible tapping chuck is characterized by its complicated design, high price, susceptibility to damage, and poor processing efficiency.

In recent years, rigid tapping has emerged as a crucial setup for CNC machining centers due to continuous performance improvement.

Because of this, rigid tapping has rapidly emerged as the most popular approach for processing threads. That is to say, the tap is held in place by a firm spring chuck, and the spindle feed and speed are controlled by the machine tool to maintain the same level of consistency.

In contrast to the flexible tapping chuck, the spring chuck is characterized by a straightforward construction, an affordable price, and a versatile application range. This means that in addition to fastening taps, it can also clamp end mills, drills, and possibly even other tools, which could result in cost savings for the tools.

At the same time, rigid tapping is frequently utilized for high-speed cutting, which increases the machining center’s productivity and decreases the costs associated with manufacturing.

Conclusion:

Machining threads is difficult because it requires expertise and expensive machinery. Therefore, Prototool has your back if you want to create standard threads that last a lifetime.