The initial experience of diving into laser cutting can leave you feeling a tad overwhelmed. What are your options? What kind of material should you use? For which materials should you use this CNC Laser Cutting Machine setting?

This comprehensive guide will delve into the essential aspects of utilizing and acquiring the finest CNC laser-cutting machine.

So, continue perusing to acquire a wealth of knowledge about this remarkable tool.

What is a Laser Cutter?

Laser cutting is primarily a heat treatment procedure. In this process, a focused laser beam helps melt the material. Coaxial gas jets are utilized to expel molten material and create slits.

The laser beam or workpiece is moved under CNC control for continuous cutting. Although it is most commonly employed in industrial manufacturing, it is also used by schools, small enterprises, and amateurs.

How Does a Laser Cutter Work?

Although “laser” is an abbreviation for a highly serious and intense term, it has a simple meaning: narrow and coherent light.

So the laser must generate intense and focused light – and if enough light is concentrated into a single area, it can cut and burn things like a hot, sharp knife.

The initial stage is to create light. However, not all light suits a laser beam; we require light beams that collaborate. We use monochromatic light, meaning all light beams have the same wavelength.

For example, the laser beam may emit only blue light instead of your lamp’s white light, which contains numerous hues and has a broad spectrum.

There are various methods for producing this type of light for laser beams. CO2 lasers generate light by energizing a mixture of gases, whereas diode lasers use electricity to excite semiconductors, and fiber lasers use light to excite fiber optics.

Also Read: Gas-Assisted Injection Molding: Innovative Plastic Manufacturing Solution

Any of these methods will provide adequate light for laser beams. The light is then directed from the source to the lenses. The lenses will make the light more directed and coherent.

That’s all there is to it! Your laser beam is now emitting very coherent light.

The laser only engraves the material at low energies. This includes heating the material surface to the point that some evaporate and leaving markings. The laser is so hot and high-power sharp that it will cut through the material.

What Materials Does a CNC Laser Cutting Machine Cuts?

Industrial manufacturing, small enterprises, small shops, home businesses, home shops, and school education can all benefit from laser engraving and cutting machines.

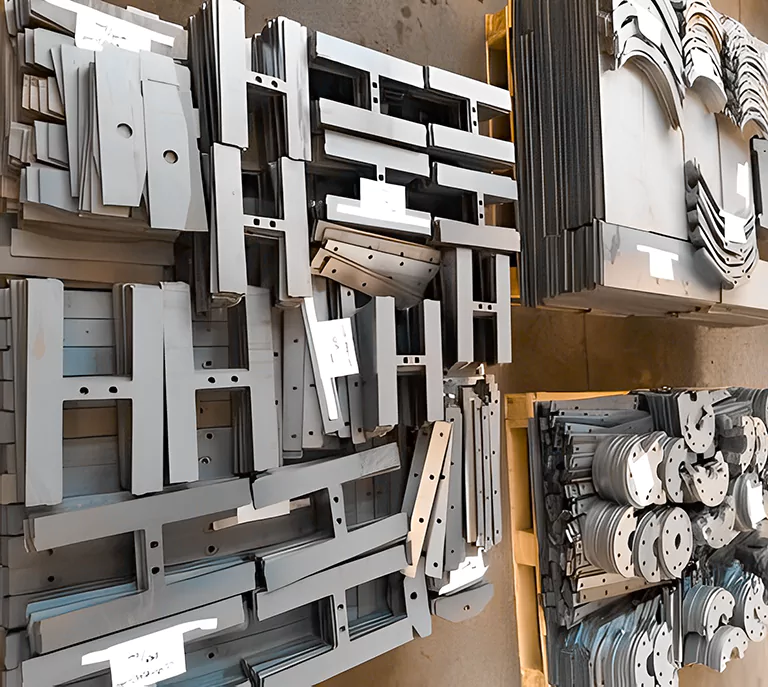

Fiber laser engraving machines are frequently employed to engrave and cut metal materials such as stainless steel, carbon steel, copper, alloys, aluminum, silver, gold, and iron.

Similarly, non-metallic materials such as wood, fabric, acrylic, leather, foam, plastic, stone, paper, MDF, and PVC are commonly engraved and cut using CO2 laser engraving and cutting machines.

Things to Consider When Choosing a CNC Laser Cutting Machine:

Take into consideration these essential factors when choosing a CNC laser-cutting machine for your business:

The Power – What Do You Want to Cut or Engrave?

A higher-power laser allows for faster setting and cutting, often requiring only one pass or fewer. As a result, a powerful laser saves time and cuts faster.

However, don’t buy a laser engraver based on raw laser machine power numbers. There is more intricacy, and some companies are secretive about the true power of their lasers.

A 10W laser, on the other hand, can cut reasonably thick wood and etch-covered metals. A 40W CO2 laser can accomplish the same but far better (engrave considerably more materials). Only strong fiber laser cutters, and industrial devices, can begin to cut metals.

Speed – How Fast Should the Cutter Cut?

Engraving speeds are critical, especially if you sell laser cut or engraved goods and want to complete each project as soon as feasible. But don’t confuse speed with laser strength; speed is simply the fastest your laser can move across each axis – it doesn’t guarantee it can cut right through the material.

It is worth considering that laser engravers have varied ideal speeds and test cuts can be used to evaluate your laser engraving machine.

Cut thicker materials slower (more passes may be required) but faster if you want to engrave and don’t want a too-dark contrast.

Size – Does It Fit Your Working Area?

The greatest laser engravers can engrave larger images and other designs; you don’t want to be limited to little tasks, so a large-format CNC laser cutting machine & engraver may be the ideal option.

Professional laser engravers have large working areas; however, keep in mind that an enclosure limits the laser’s working area slightly.

Under $1000, laser engraving machines typically feature open-air systems (rather than enclosures) and can provide good sizes for the budget. The cheapest lasers, for example, may only have 150 x 150 mm working areas, whereas expensive lasers often have more than 400 x 400 mm. This will suffice for most hobbyist projects and huge engravings.

Performance Quality – Does It Meets Your Quality Expectations?

Engraving precision is essential for high-quality engraving. Combining cut depth, focal point, and components such as stepper motors generates engraving precision.

However, it’s worth considering that even low-cost laser engravers are incredibly accurate. In fact, no laser cutter might work well if you don’t optimize your laser beam focal length and settings. Furthermore, speed, percentage power (compared to the cut materials), whether you have air assistance, and many other aspects influence the ultimate quality of your item.

Price – Does It Fit Your Budget?

Nowadays, you can acquire competent laser engraving equipment for under $300. However, it doesn’t mean you should because they’re frequently made from lower-quality materials and aren’t as accurate and trustworthy as you’d like.

It is important to remember that there is a difference between an excellent budget laser engraving machine and a laser engraver that is a great fit for your budget. And there’s nothing wrong with using less expensive laser engraving equipment if you want to save money but don’t need all the added power.

However, consider your current and future needs before selecting a CNC laser cutting machine.

Gas Assistance – Which One is Ideal For You?

Oxygen, nitrogen, and shop air are the most typical support gases. Certain laser-cutting specialists also utilize the use of argon and oxygen-nitrogen combinations.

The primary objective of the help gas is to clear away the material that has been melted by the laser so that it does not begin to harden as the laser advances.

In addition, nitrogen and argon can inhibit oxidation, whereas oxygen is responsible for producing an exothermic reaction that boosts the temperature of the cutting process.

Software Compatibility – Does It Work For You?

Another consideration is that while you have control over the software you use to design, you do not have complete control over the laser software. It is dependent on the laser.

Some laser manufacturers provide their laser control software, while others integrate with third-party software already in place. The laser program handles the majority of your interactions with it. Using the laser program, you can load photos and possibly vector drawings (as well as g codes, depending on your laser).

Then, change the software’s laser power and speed settings before pressing the start button. If your laser is capable of rotaries, your laser software will include a setting for “cylinder engraving.” It can regulate the laser and rotational to engrave on circular objects.

Also Read: What is CNC Machining: A Professional Guide

CNC Laser Cutting Machine Vs. CNC Laser Engraving Machine

These machines have a similar working mechanism, i.e., they use custom models to create parts. So how do you differentiate between your needs for a laser cutter vs. a laser engraver? Let’s understand the difference in the table below.

| CNC Laser Cutters | CNC Laser Engravers |

| Laser cutters employ intense light beams to vaporize material, leaving the finished product behind. In subtractive manufacturing, these cutters use vector files to precisely cut your desired product, cutting off chips and cleanly separating these areas. CO2 lasers are commonly used in laser cutters, and even low-end models can swiftly and precisely cut through acrylics, plastics, and wood. | Laser engraving devices create an image, logo, or design by engraving it into the material’s surface instead of cutting completely through it. While engraving is most commonly used to add a company logo or message to a sign, it may also be used to permanently imprint monochrome artwork onto a piece of wood. Images in SVG, jpg, png, or AI formats are used for this purpose. The process often involves grid engraving, in which the laser moves horizontally, line by line, cutting away varying material thicknesses to create a contrasted and legible image. Lasers with small spot sizes and short focal lengths are used by engravers to create precise designs. |

Conclusion:

Understanding your usage needs in a CNC laser cutting machine helps you pick the ideal machine for your short-term and long-term usage.

By utilizing this comprehensive guide, you can better understand how a CNC laser cutting machine operates and the range of materials it can cut and obtain valuable insights on selecting the perfect one for your projects.