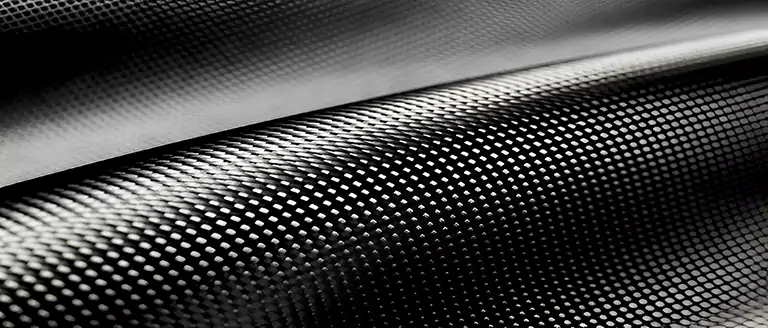

The term aerospace machining tells it all when it comes to advanced composites. Besides, as the manufacturing industry advances, composite materials are coming together to produce the aerospace industry’s future, with the ultimate goal of fuel efficiency.

The increased reliance on carbon fiber composites in manufacturing aircraft components for military and commercial aircraft has been a major driver of the increased use of advanced composites in the aerospace machining market. The industry requires high-performance materials with high mechanical and thermal capabilities and materials with low weight and production costs.

What Factors Should Be Considered in Aerospace Machining?

Honeycomb materials, often known as honeycomb structures in the aerospace industry, are primarily used in composite materials. Honeycomb sandwich structures are frequently utilized in the aerospace sector to create various wall panels, airfoils, bulkheads, hatches, floors, engine covers, tail nozzles, silencers, heat insulation panels, satellite star shells, and so on.

In this industry, five-axis linkage CNC machine tools have the same machining efficiency as two three-axis machine tools. It can potentially remove the investment in some large-scale automated production lines, saving a significant amount of floor space, work between multiple manufacturing units, and transportation time and expenses.

Carbon Fiber Applications in Aerospace Machining:

Did you know that carbon fiber is 1-4 times stronger than ultra-high-strength steel, yet its density is only 5/1 that of steel? Carbon fiber is not only a unidirectional belt and woven fabric (continuous fiber), but it is also a powder, staple fiber, medium, and long fiber reinforced composite material that can be treated and molded using the injection molding method.

Moreover, carbon fiber resin matrix composites are currently the most frequently used, with the greatest promise in the automotive industry.

But How are Aircrafts Parts Material Selected?

Below are important considerations for material selection in the aircraft sector.

Strength in parts results in a stronger whole.

These advantages have led to using carbon fiber composites in producing structural aircraft elements ranging from wings and seats to overhead compartments, brackets, and more. Hence, advanced composites are replacing metal components in many elements of aircraft manufacture due to their potential to achieve less-weight structural parts. It has also made carbon fibers more accessible to automotive, energy, marine, and infrastructure industries.

Improved fuel efficiency isn’t the only way to cut costs in aerospace machining parts manufacturing by using modern composites. While composite materials may be more expensive to create than standard metals or non-reinforced plastics, their increased lifespan, higher fuel efficiency, and lower manufacturing costs can offset the initial cost during the product’s lifetime. This makes carbon fiber a feasible alternative that aerospace firms are increasingly investigating.

Advanced composites outperform metal.

Compared to traditional materials such as aluminum alloy and metal, modern composites such as carbon fiber offer a high-performance solution for producing lighter-weight, higher-strength structural aircraft components. It can help lower the carbon footprint by improving fuel efficiency in high-flying applications.

Carbon fiber’s lightweight quality matches its accompanying strength, so improved composites are vital to the aerospace machining industry’s future. Additional benefits of the reinforcing fibers, which leading aircraft manufacturers Boeing and Airbus use, include:

- Corrosion resistance.

- Decreased production costs.

- The capacity to tolerate high temperature and high-pressure situations.

- Stiffness and flexibility.

Advantages of Using Carbon Fiber in Manufacturing:

Carbon Fiber Composites Improve Aerodynamic Performance

Aerodynamics is crucial in influencing an aircraft’s fuel economy. The more streamlined an aircraft’s design, the more fuel-efficient it is. Carbon fiber composites may be accurately produced to provide complicated yet smooth geometrics, allowing engineers to optimize the airplane’s aerodynamics. Furthermore, carbon fibers are robust, which aids in the design of seamless swept wing designs. The aircraft’s fuel consumption rate can be reduced by up to 50% by reducing aerodynamic drag.

Carbon fibers aid in the development of more fuel-efficient aircraft.

The lighter a plane is, the less expensive it is to run and maintain in the aviation business. The lightweight design improves fuel efficiency, lowering the overall cost of operating commercial aircraft. Did you know? Carbon fiber composites are incredibly strong and relatively lightweight. An aircraft made with carbon fiber composites can be nearly 20% lighter than an aircraft built with aluminum.

In fact, experts estimate that every kilogram of weight saved by employing carbon fibers saves around $1 million throughout the airplane’s life.

They are suitable for creating complex shapes.

Metallic alloys utilized in traditional airplane manufacture are typically brittle. As a result, engineers are turning to carbon fiber composites with high malleability. This enables the creation of more complicated shapes, introducing a new and innovative domain to aircraft engineering. Building complicated forms reduces the number of aircraft parts as well as the number of joints and fasteners necessary to install a component.

There are two benefits to doing so: First, fewer joints and fasteners would result in speedier assembly time; second, every hole drilled to attach joints and fasteners would result in a possible crack-initiation site. Having fewer of them is thus expected to make the structure stronger and more dependable.

Carbon Fiber Composites Aid in the Use of Fewer Aircraft Parts

The amount of parts required to construct an airplane also influences its weight, aerodynamics, and fuel efficiency. More parts required to create an airplane means more manufacturing time, weight, maintenance, and expenses. Fortunately, carbon fiber composites can be easily produced and molded to combine numerous pieces into a single, more robust, and reliable structure.

Carbon fiber is resistant to corrosion

Another advantage of employing carbon fiber composite materials in aircraft manufacture is that they are more corrosion-resistant than metal alloys. This makes them an ideal choice for aviation since corrosion resistance means longer part lifespan, better maintenance, and lower operating expenses. Furthermore, carbon fiber has great crack and fatigue resistance when paired with a stronger resin matrix.

Carbon Fiber Composites Allow for Quicker Fabrication

The fabrication process is expected to be accelerated by the faster assembly and the need to create fewer parts. Carbon fiber composites are incredibly flexible, enabling complex shaping and seamless integration into unified structures. As a result, producers have fewer pieces to fabricate and assemble. This will improve the time to market and speed up the manufacturing process.

Additional Aerospace Industry Technologies Being Adopted Today:

Welding with a Laser Beam:

Laser welding delivers faster and more precise processing compared to conventional welding procedures. As a result, laser welding is an excellent material-handling solution when great precision and reproducibility are required. It is also an excellent method for combining incompatible materials, which can be difficult with typical welding procedures. The fact that laser welding transfers extremely little heat to the material being fused is perhaps its most significant advantage.

Using this technology, there is no heat-affected zone formed around the weld. Moreover, no cracking or material weakness could jeopardize the joint’s performance. Pressure vessel welding, orifice drilling, proximity sensor welding, leading-edge hole drilling, battery welding, and sensitive electronics glove box welding are all examples of laser machining applications.

Additive Manufacturing:

The aerospace machining industry was the first to identify the enormous potential of additive manufacturing (AM) for developing parts with advanced materials and novel geometries. Most components are printed using powder-bed laser printing technologies. However, alternative laser and electron beam techniques are also employed. AM can also create lattice structures, particularly within the fuselage, saving weight and aiding heat dissipation.

AM simplifies assembly and reduces potential failure sites by replacing multiple parts with a single component. Fused deposition modeling (FDM) is an additive manufacturing (AM) technology that deposits ultra-thin layers of semi-molten thermoplastics to construct semi-hollow objects, such as honeycomb structures for unmanned aircraft system wings, lowering weight while increasing strength.

AM is also progressing toward producing larger pieces up to two meters in length. For example, GKN Aircraft recently collaborated with the US Energy Department’s Oak Ridge National Laboratory. Their collaboration aimed to develop a large-scale additive manufacturing technique specifically for manufacturing significant titanium aerospace components.

Five-Axis Machining Setup:

The structure of the five-axis machining center varies, and the machine tool’s structural design impacts the equipment’s performance from the foundation, determining the rigidity, machining accuracy, stability, operability, and so on.

The advantage of five-axis simultaneous machining is that it can continuously maintain the appropriate angle between the tool feed direction and the workpiece surface, resulting in better surface quality and a better approach to the chamfer while also improving tool life, saving time in one clamping, and lowering the machining error rate.

Five-axis linkage is widely employed in the mold manufacturing sector for curved surface processing, while three plus two-axis machining centers are used for flat machining.

Conclusion:

Using carbon fiber composite materials in the construction of airplanes provides engineers with greater freedom when planning aerodynamic efficiency and fuel savings. Commercial aerospace machining manufacturers may reconsider constructing designs in which the wings and fuselage integrate to improve the plane’s lift-to-drag ratio.

Carbon fiber has been used in aircraft production since the 1970s. With recent technological breakthroughs, we can expect to see more powerful and unique aircraft designs.

What are your thoughts on this?