Thin Wall Injection Molding – Definition, Tips, and Design Considerations

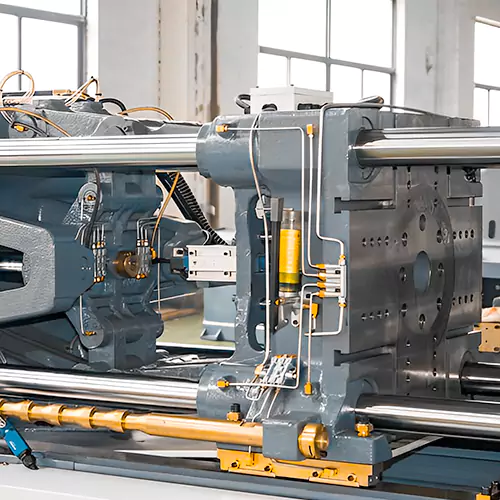

Injection molding is a common and adaptable manufacturing technology that allows businesses to generate high-volume production runs at a cheap cost per part without losing quality. It is extremely reproducible and capable of creating strong components that fulfill precise mechanical and dimensional specifications. Thin wall injection molding can be used when a company has to […]

Gas-Assisted Injection Molding: Innovative Plastic Manufacturing Solution

In today’s fast-paced world, the manufacturing industry is one of the most innovative, always setting new norms. In this growing and evolving industry, gas-assisted injection molding is an innovative plastic manufacturing technology that produces high-quality products. Today, we will dive further into the manufacturing process by discussing what it is and its various types, applications, […]

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can […]

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating […]

Introduction to the Production Technology of Plastic Injection Molding Parts for Automotive Products

Today, plastic injection molding has become a widely used production technology in the automotive industry for manufacturing complex, high-precision, and durable components that meet strict safety, reliability, and quality standards. The process of producing plastic injection molding parts for automotive products involves injecting molten plastic into a mold cavity, where it solidifies and takes on […]

What are the Characteristics of Injection Molding service companies in China?

Injection molding is a popular method of manufacturing plastic goods, provided by businesses specializing in injection molding service companies that use injection molds to produce large quantities of products quickly and at a low cost. Because of its low cost and high capacity for producing a huge quantity of products quickly, it is a common […]

Plastic Products Supplier Prototool: “Specialized in Special Engineering Material Applications”

Are you looking for a trusted plastic products supplier for your business? Whether in the beauty industry or other grossing business markets like automobile, electronics, consumer products, aerospace, etc., plastic products are used in every industry today. From medical products and supplies to beauty boxes, makeup product containers, furniture, and other products used in our […]

Ways to Find Your Desired Injection Molding Service?

Nothing beats plastic injection molding service as a production process for making plastic parts. It outperforms other plastic molding methods because the process is less complicated but more reliable. It has the versatility that intricate engineering designs require and the cost-effectiveness that many businesses seek to keep their bottom line healthy. But is it worth […]

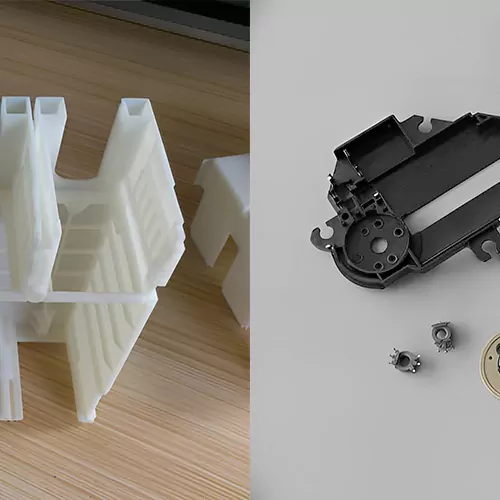

3D Printing vs. Injection Molding, Which is better?

You’re probably already considering potential production methods for your project. So, which production method is best? 3D printing vs. injection molding, and why? With this detailed guide, we will help you choose between injection molding and 3D printing to give life to your project by comparing and contrasting the two processes and highlighting their respective […]

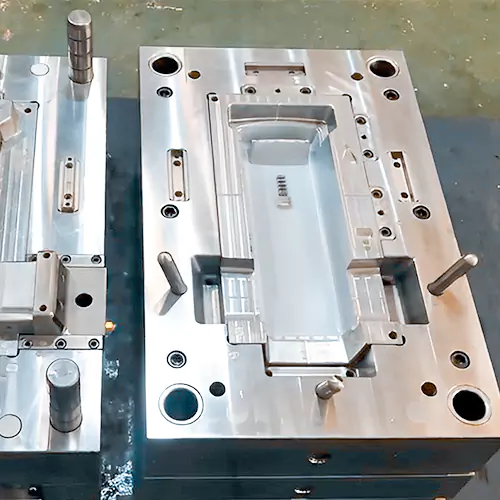

In-Depth Guide On The Injection Molding Gate

While injection mold tools are difficult to design and manufacture, their essential concepts are simple to grasp. The mold comprises two faces, one of which has a cavity and core set into which the plastic is injected. The plastic – which, as the name suggests, is injected into the mold via a sprue that feeds […]