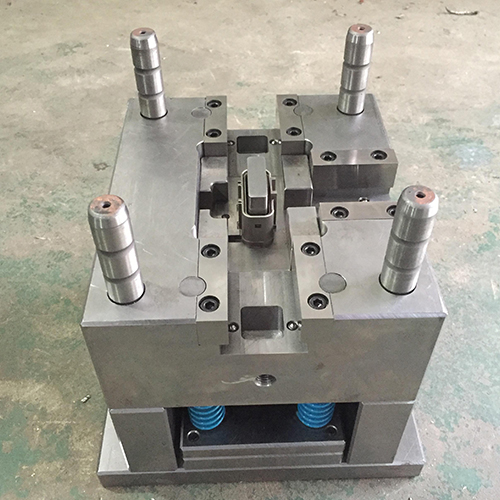

In-Mold Assembly: The Future of Efficient Manufacturing

In-Mold Assembly: Streamlining production with precision. Explore its principles, applications, and the future of manufacturing.

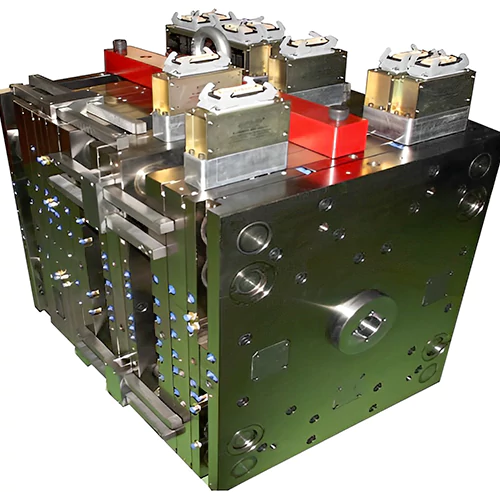

Stack Molding: Doubling Production Without Doubling Costs

Understanding stack molding: a game-changer in doubling production without inflating costs. Ready to revolutionize your molding process?

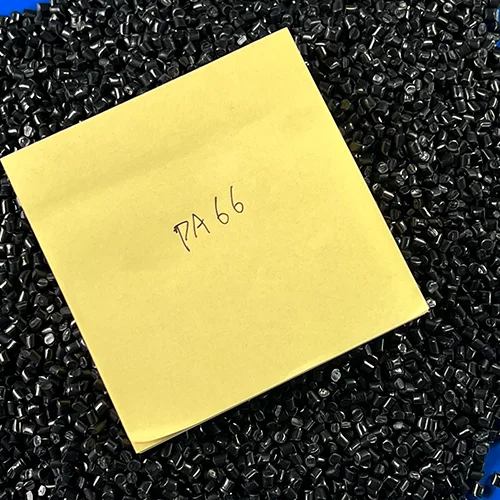

Polyamide Injection Molding Process Highlight: A Brief Overview

The beauty of plastic injection molding is that you may choose from various materials, each with advantages and disadvantages. Polyamide, better known by its brand name, Nylon, is one such plastic material frequently used in injection molding. This thermoplastic’s outstanding blend of electrical and mechanical qualities makes it a great choice for applications in various […]

Polystyrene Injection Molding | Plastic Injection Molding

Polystyrene injection molding is at the vanguard of modern manufacturing, providing an unrivaled mix of adaptability, cost-effectiveness, and ease of use. Polystyrene is a great example of the art of molding because it can be made into many different shapes, such as wrapping foams. Now, let’s learn more about the polystyrene injection molding technique. Characteristics […]

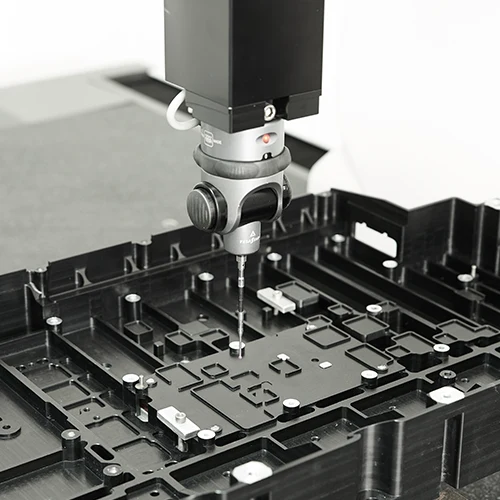

The 101 of Plastic Molding Quality Control – A Detailed Guide

Plastic molding quality control is essential in plastic injection molding because it ensures that goods are perfect. It requires careful steps for planning, developing, designing, and making. The proper mold design method and the correct process planning ensure customers get high-quality plastic products that meet their needs. Precision production control helps stop and eliminate mistakes […]

The Causes and Solutions of Warping in Injection Molding

Warpage, the injection molders‘ nemesis! It’s a common problem, especially during the fine-tuning process. Now picture a part that should match the cavity but decides to deviate, resulting in a warped section. In this scenario, even non-experts can spot the bending or twisting. So what do you do in this situation? Simple: avoid unintentional bending […]

HDPE Injection Molding | Plastic Injection Molding Service

HDPE injection molding has become a game-changing technology in modern manufacturing, changing how many goods are made. This article gives a brief overview of HDPE molding. It talks about how precise, efficient, and essential it is to many different businesses. What is HDPE? High-density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin with a […]

Injection Molding Nozzle – Types, Defects, and Characteristics of a Quality Nozzle

Injection molding is a popular and widely used way to make things. An injection molding nozzle is a key part of the ejector system at the bottom of the molding machine. Its main job is to move melted plastic from the barrel into the mold, a key part of making the end product. The mold’s […]

Vacuum Voids in Injection Molding: Unraveling The Most Common Injection Molding Defect

Although the plastics manufacturing business has been more productive thanks to plastic injection molding service, its finished products don’t always meet the client’s expectations. From lack of efficiency in managing the injection molding process to operating errors, production errors, and whatnot – different aspects of this production approach can lead to common injection molding defects. […]

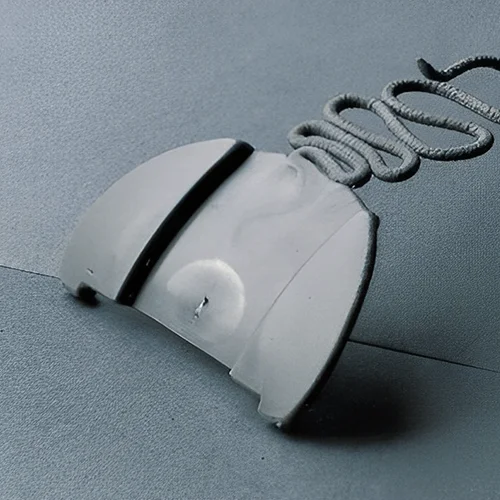

Jetting in Injection Molding – Identifying the Cause and Troubleshooting the Defect

Jetting occurs in a molded component when molten material is injected into the mold cavity and starts solidifying before it fills the cavity. It is a type of distortion caused by this premature solidification. Furthermore, jetting is frequently visible as a squiggly line on the surface of the final component, typically leading from the original […]