If you explore, you will find that many items we use regularly are often made of more than a single material. For example, if you have a look at a pair of scissors, there is the usage of a plastic handle and metal blades. For us, it is a regular household thing that we use pretty often. Though this might be simple enough, have you ever thought about how this regular-use item is made? If you explore, engineers need to think and finalize the method to ensure that we can use these different materials together to meet different needs. These methods are frequently needed in manufacturing such materials as the pair of scissors we just mentioned. Out of the general methods used to adhere to these essential needs, insert injection molding is one critical service that is frequently needed.

We will explore how insert injection molding works today. But before we get into further details about how it works, let us see what the insert molding is all about.

Molding, what is it all about?

Before we get into insert molding, let us understand what molding is. In simple language, it is the process by which we can convert raw material to a particular shape or form for the final desired and finished product.

Molding techniques vary

Different materials require different molding techniques. The overmolding process and insert molding design types are the most popular molding techniques used.

They deliver the best results and are thus considered one of the best in the current market.

Making helpful plastic and making them into specific finished products like plastic chairs involves several processes. The first and foremost process is melting and, thus, softening the plastic at very high temperatures. Then different methods are used to mold them into the specific finished products needed, like plastic chairs.

What is insert molding?

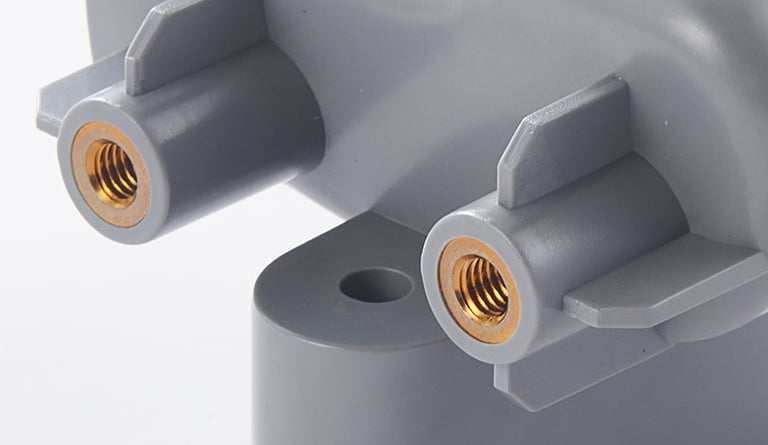

If you are not aware, insert molding is a highly powerful tool. The tool bolsters the form and function of plastic injection molded parts. Through this process, there are the injection of other parts, usually metal parts, into the molded material directly.

Let us take an example. As mentioned already, in the case of the scissor, there is a plastic handle into which the metal blades of the scissors need to be injected or inserted. Here are the metal inserts that need to be inserted or injected into the mold before the plastic injection.

Once the insertion or injection of the metal parts has been made into the mold, the exact need to be surrounded by the plastic. The injection process must be such that the metal part that has been inserted remains bonded firmly to the material it inserted. The same must hold good even after cooling and curing.

In insert injection molding, you need to understand that it works on the same principle as plastic injection molding. In case of the same, molten resins are inserted into the plastic mold. Once the requisite injection of the plastic resins has been made, they are allowed to cool off and solidify. Once this is done, the inserted parts are ejected or removed from the mold they had been inserted or injected into.

The main difference here is the insertion of metal inserts into the molten resin, which is before the mold is closed. Thus, in most cases, plastic usually covers the entire product or the metal inserts. It is entirely engulfed in molten plastic, and there are no cracks. Instead, it is done in a way that there is a uniform wall thickness throughout.

As already explained earlier, the inserted product can be as simple as metal blades, as in the case of scissors. But in some instances, there may be some inserts that can be like complex machines too.

Why is insert Injection molding often preferred?

Compared to other methods, it is seen that the insert injection molding method is often used and why insert molding services are widely used. Many reasons are there for the same.

They are more durable.

If, instead of inserting molding for the attachment if screws are used, then cracks can develop. But owing to this mechanical process, after some time, cracks might develop.

With the screw-based assortment procedures, there is a much greater risk of wear and tear. The chances of loss here, as a result, are many.

On the other hand, for the insert molding process, the entire product is covered by plastic. It is naturally formed around the metal part or product. Here there is a mechanical bond.

They, therefore, are much more durable and thus also more preferred.

It can help to provide a soft grip.

With the insert molding process used for scissors, there is a soft and more convenient grip. In addition, it provides a good quality product design in this insert molding process.

The plastic injection molding process is often used because it enables manufacturers to make a much more reliable structure. It also increases the strength of the finished product that is made with the help of this insert injection molding process.

Insert Injection molding components are more reliable to use

It is seen that components made from insert molding processes are free from faults and failures. The reason is this is a highly advanced process that ensures complete precision. It is a fundamental reason for the popularity and wide use of the process.

The process ensures design flexibility.

Design flexibility in almost every industrial process is a vital requirement. The good thing about the components made from the insert molding process ensures that they are flexible. Flexibility is beneficial in different industrial processes.

Made from one sheet of material

Another great advantage of the insert molding process is that the entire finished product is from a single sheet of plastic. Thus, it helps in the consistency of the finished product.

These are the main reasons that the industry often seeks to insert injection molding.

Helps the finished product to have an excellent exterior finish

One significant benefit of using the insert molding process is that it ensures that the finished products’ exteriors have great shape and quality.

Designing guidelines for the insert Injection Molding

Knowing the advantages of insert injection molding, specific design guidelines are crucial for maximizing its benefits.

After now knowing the basics of the insert molding process and the benefits associated, if you plan to avail of the insert injection molding, you need to ensure that the service provider ensures some of the following things. These are similar to the conventionally molded parts in some ways.

Maintaining consistency in the wall thickness.

To ensure that you have a suitable finished product through the insert-molding process, you need to ensure that the wall thickness is evenly maintained.

Carefully consider the placement of the inserted parts

If there is an error in the placement of the inserted parts, problems are bound to happen following the process. In line with this, it is to be ensured at all times that the position of the inserted material, usually metal, is rightly placed.

Ensure there is the use of top-class machinery for the process

To derive the best results, you need to keep in mind that there is a need for the most advanced machinery is needed for the insert molding process. Thus, if you are availing of insert injection molding, you need to make sure that the providers of the same use the latest and the most advanced machines to deliver the best results.

The service providers also need to ensure that all the fed data is correct. If this is not done, any minor misalignment in the process can lead to a complete failure of the product.

Thus, we can say that the service providers need the best machines and an expert team to handle everything correctly to avoid any disaster resulting from the errors.

The inserts need to be of the highest quality.

In addition to coordinating other factors, like machine input, the quality of inserted components must also be exceptionally high.

If one is to insert metal parts, one needs to ensure that the inserts are solid, so they do not break down under any condition. If that happens, then the same can have profound implications as well.

Conclusion

To conclude, we can say that the insert-molding process is prevalent now in the industry. It is now being widely used owing to the many benefits it has. So, if you are using it, you can surely enjoy the benefits mentioned here. But at the same time, you need to employ only the best provider of insert molding services to ensure you have the best results.

Thus when choosing the providers of this very beneficial process, you must ensure that all the considerations for selection mentioned here are adhered to.