Injection molding is a popular method of manufacturing plastic goods, provided by businesses specializing in injection molding service companies that use injection molds to produce large quantities of products quickly and at a low cost. Because of its low cost and high capacity for producing a huge quantity of products quickly, it is a common manufacturing method.

Because China has a highly skilled labor force and relatively low production costs, the majority of corporations outsource the manufacturing of their injection molding products to China.

Hence, the scale of the injection molding market in China is enormous, and the industry that deals in injection molding face severe competition in China and other countries.

But what about the injection molding service companies in China that make them so much better and more preferred by customers worldwide? Let’s investigate this and the essential qualities that customers look for in injection molding service companies in China so that they can meet all of their production requirements.

Why Do Clients Prefer China-Based Injection Molding Service Companies?

In many cases, Chinese manufacturers can make injection-molded products in a period that is far quicker than the time frame that is typical for manufacturers in other nations. Having your injection-molded products manufactured in China rather than elsewhere in the world can be an extremely time- and money-saving strategy when producing your goods.

If the production firm you work for needs injection molding services to create plastic parts, one of the first and most important decisions you will need to make is whether you want to hire an injection molding facility in your nation or one located elsewhere.

Although several countries offer mold-making services, China is a key player in this industry. This is because the price of injection molding in China is far lower than in the United States or Europe. You may save 20–60% and have a shorter turnaround time if you purchase an injection mold built in China.

Because of this, and more specifically because of the superior service that companies in China offer in terms of cost, quality, turnaround time, and familiarity, customers frequently find that outsourcing their work to companies located in China or investing in Chinese companies is the best option for them.

Not to mention how the high-regional concentration, especially in the injection molding service companies located in the Pearl River Delta and Yangtze River Delta. It is easier to find more experienced and skilled manufacturing professionals in China for clients looking for guaranteed quality manufacturing.

Key Characteristics of China-Based Injection Molding Service Companies:

Quality:

There is a good reason why there are many injection mold producers and injection factories in China. Manufacturing has been an essential part of the Chinese economy for many years. China is home to many injection mold makers who provide their products to businesses and individuals in various countries.

Manufacturers and retailers in the United States have, for some time now, been concerned about the quality of injection-molded products coming from China. However, recently there has been a notable improvement in the quality of goods manufactured in China. This can be attributed partly to China’s commitment to quality control. Consequently, many businesses are looking to China to fulfill their injection molding needs.

There are a great number of reasons that have contributed to the quality improvement of items created in China. First, Chinese manufacturers emphasize quality assurance, extensively use engineers with relevant skills, and purchase cutting-edge machinery.

Second, because of improvements in education and training, China’s labor force has become more knowledgeable and has accumulated more experience. At long last, the government of China has begun to crack down on firms that produce goods of poor quality and those who counterfeit goods.

Due to these efforts, the quality of products manufactured in China using injection molding is now on par with the quality of products manufactured in industrialized countries. This is fantastic news for businesses that rely on these products, and it is also good news for customers, as they can be confident that they are purchasing a product of high quality.

Price:

The cost of the item is significantly reduced in China, and the country’s price ratio is among the lowest in the world. However, the prices of Chinese goods are determined by various factors. The ultimate price is determined in part by the kind of material that was used, as well as by the dimensions and intricacy of the product and the number of items that were manufactured.

Additionally, when purchases are placed through your supplier, Chinese injection molding service companies frequently provide discounts. Therefore, it is essential to obtain estimates from various sources before making a decision. Meanwhile, we may supply you with an offer that is certain to be included in your catalog.

This may be a good deal. The many tools produced in China always opt to manufacture molds and molds. Still, the price is significantly lower than what American businesses offer, even though the quality is comparable, but to be. The price is far lower than the one, increasing benefits and labor costs for your country.

Manufacturing Infrastructure:

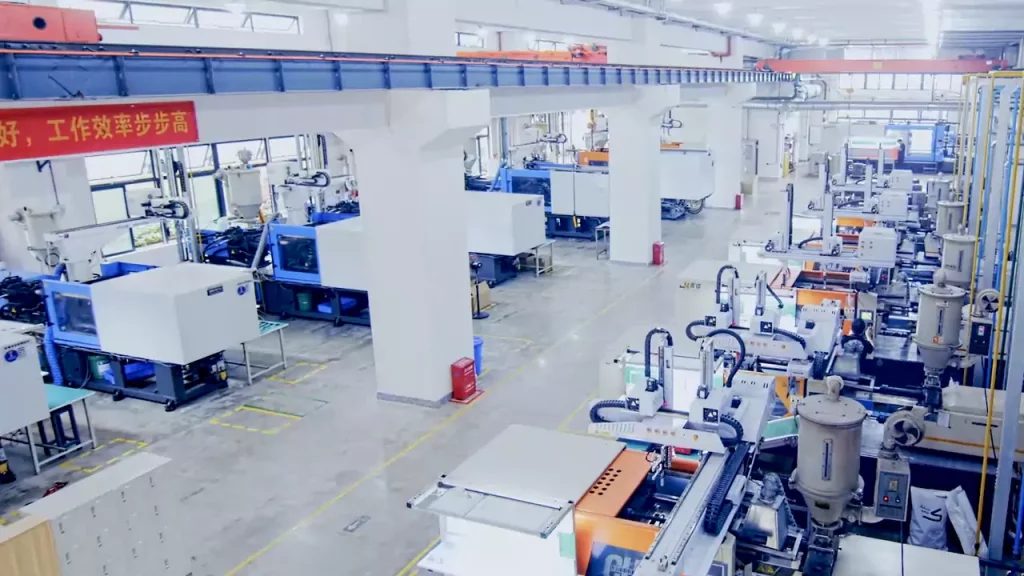

The massive manufacturing infrastructure in China that is outsourced to other countries is one of the most valuable economic assets in the country. It has been estimated that China is responsible for more than 80 percent of the world’s electronic goods manufacturing and 70 percent of the world’s apparel production. The expansion of manufacturing in China has been a driving force behind China’s overall economic development, which has helped bring millions of people out of poverty.

The infrastructure of China’s manufacturing sector is also a key source of employment for many people. However, in recent years, China’s manufacturing industry has slowed as the country has begun to move up the value supply chain and focus on high-end products. This is due to China’s concentration on moving further up the value chain.

As a direct consequence, China’s industrial infrastructure is not the economic powerhouse it once was. Despite this, it continues to play a significant role in the Chinese economy and is one of the primary drivers of employment.

Turnaround Time:

The lead time for injection molding from China is relatively short. Varying on the size and intricacy of the tool, this process can take anywhere from three to eight weeks to complete.

When considering China as a location for manufacturing injection-molded items, lead time is a crucial issue to keep in mind. It takes more time to manufacture injection-molded products in China than in developed countries like the United States, Japan, or Germany.

The time it takes to get products that have been injection molded from China can range anywhere from four weeks to three months, depending on the degree of difficulty of the product and the quantity of the order. The extended delivery timeframes for injection molded products originating in China can be attributed to several different variables, including the amount of time required to produce molds, test them, and transport them.

Additionally, the typical wait times for Chinese suppliers are far greater than those of their Western counterparts. Injection-molded products originating in China can, however, have their delivery times reduced in various methods.

For instance, suppliers may move their facilities closer to the production locations, and orders could be segmented into several separate, smaller orders to shorten the overall wait times. Hence, with careful planning and execution, to shorten the amount of time needed for the delivery of injection-molded products originating in China.

The Experience and Knowledge that Chinese Manufacturers Possess:

The Chinese manufacturing industry has accumulated vast experience and knowledge over the years. They have been in the business for many years, allowing them to acquire a profound knowledge of the production procedure and hone their expertise in creating high-quality goods. Consequently, they can offer their clients superior support and service.

In addition, they can provide competitive costs, making them an appealing choice for companies that want to purchase products from China. Businesses looking for high-quality products at more affordable costs could benefit from working with Chinese producers.

These injection molding service companies can offer superior service and assistance because they have the necessary knowledge and skills. They have a vast amount of experience and knowledge in this field. They bring great experience and expertise to the table, allowing them to deliver outstanding service and support. Many companies have decided to obtain their supplies from China. To satisfy the requirements of your plastics firm, choose a Chinese mold manufacturer right now.

Conclusion:

Overall, the quality characteristics, professionalism, years-long expertise, and know-how of the manufacturing process and the market that China-based injection molding service companies have made these companies like Prototool a better investment option for clients looking for guaranteed quality production.