ABS Machining | Challenges, Helpful Tips, Material Finishing Methods, & More!

A professional ABS machining company shares information about the challenges of machining ABS and how to make top-quality plastic parts.

Tools, Techniques, Key Parameters And Surface Finishing Method For Steel Machining

Prototool is a proficient metal machining company, with a special expertise in CNC steel machining, and we’ll share our advanced skills to you

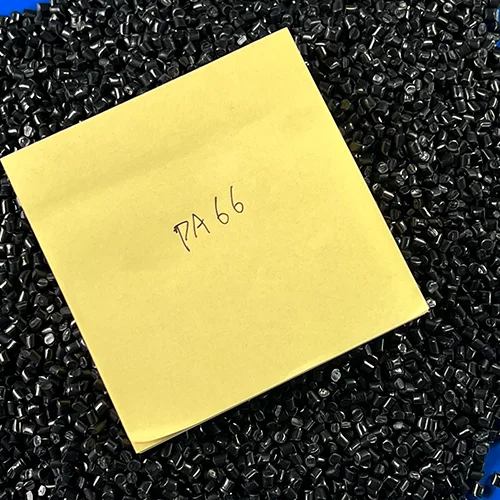

Polyamide Injection Molding Process Highlight: A Brief Overview

The beauty of plastic injection molding is that you may choose from various materials, each with advantages and disadvantages. Polyamide, better known by its brand name, Nylon, is one such plastic material frequently used in injection molding. This thermoplastic’s outstanding blend of electrical and mechanical qualities makes it a great choice for applications in various […]

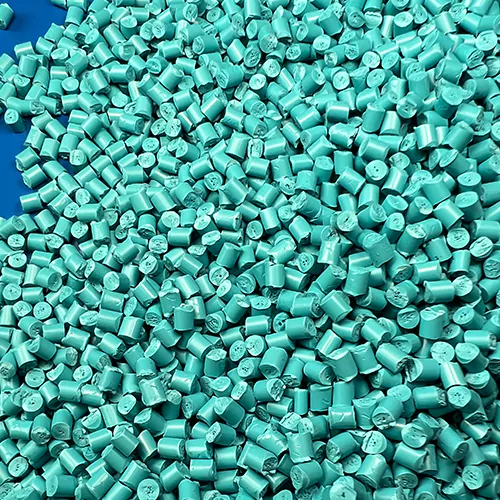

Polystyrene Injection Molding | Plastic Injection Molding

Polystyrene injection molding is at the vanguard of modern manufacturing, providing an unrivaled mix of adaptability, cost-effectiveness, and ease of use. Polystyrene is a great example of the art of molding because it can be made into many different shapes, such as wrapping foams. Now, let’s learn more about the polystyrene injection molding technique. Characteristics […]

HDPE Injection Molding vs. LDPE Injection Molding

Polyethylene (PE) is a versatile thermoplastic that can be made into various forms based on its chemistry. The most common types are high-density polyethylene (HDPE) and low-density polyethylene (LDPE), but there are also many other types. Despite sharing some commonalities, HDPE injection molding vs. LDPE injection molding exhibit distinct chemical structures. These differences give rise […]

HDPE Injection Molding | Plastic Injection Molding Service

HDPE injection molding has become a game-changing technology in modern manufacturing, changing how many goods are made. This article gives a brief overview of HDPE molding. It talks about how precise, efficient, and essential it is to many different businesses. What is HDPE? High-density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin with a […]

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts. Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. […]

The Importance of Shrinkage of Injection Molding Plastics

Molding done with injection molding plastics undergoes a process known as shrinkage, which contracts as it cools after being injected. Most of the shrinking happens inside the mold while it is cooling, but there is still some shrinking after the part has been ejected since it continues to cool. It indicates the extent to which […]

How to Manage the Color Difference Of Injection Molded Parts

In general, chromatic aberration is a prevalent fault in plastic injection molding. And it is found in the injection molding process. But that’s not all the defects that may occur in such parts related to their color differences. As we all know, several factors influence the color difference of finished injection molded parts. It’s no […]

Plastic Products Wall Thickness: The Most Recommended Reference

The wall thickness of injection molded plastic products significantly impacts their quality. If the wall thickness is too thin, it will be challenging to meet the requirements for strength and rigidity and fill the cavity for large and complex products. Too thick will not only waste raw material but also quickly generate bubbles inside the […]