ABS加工|課題、役立つヒント、素材の仕上げ方法など!

ABS加工のプロフェッショナル企業が、ABS加工の課題と最高品質のプラスチック部品を作る方法について情報を共有する。

Tools, Techniques, Key Parameters And Surface Finishing Method For Steel Machining

Prototool is a proficient metal machining company, with a special expertise in CNC steel machining, and we’ll share our advanced skills to you

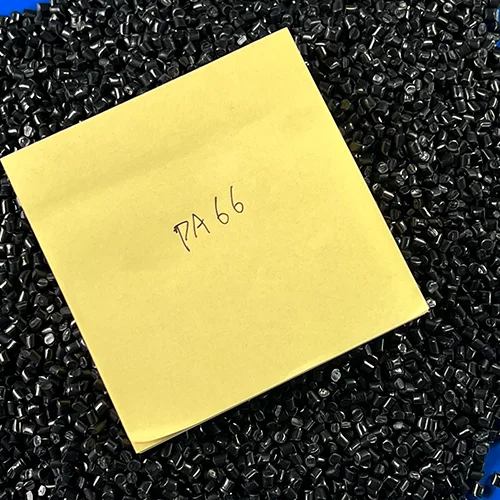

Polyamide Injection Molding Process Highlight: A Brief Overview

The beauty of plastic injection molding is that you may choose from various materials, each with advantages and disadvantages. Polyamide, better known by its brand name, Nylon, is one such plastic material frequently used in injection molding. This thermoplastic’s outstanding blend of electrical and mechanical qualities makes it a great choice for applications in various fields. Let’s dive deeper into thermoplastic polyamide injection molding to help you better understand your possibilities. Understanding Polyamide: PA is an abbreviation for polyamide, often known as Nylon. It is a very important thermoplastics class for high-performance engineering applications. It features characteristics that are well-balanced overall. They have repeated amide connections, denoted by the notation […]

Polystyrene Injection Molding | Plastic Injection Molding

Polystyrene injection molding is at the vanguard of modern manufacturing, providing an unrivaled mix of adaptability, cost-effectiveness, and ease of use. Polystyrene is a great example of the art of molding because it can be made into many different shapes, such as wrapping foams. Now, let’s learn more about the polystyrene injection molding technique. Characteristics of Polystyrene: Polystyrene is usually (but not always) a homopolymer, which means it is made up entirely of the monomer styrene in conjunction with itself. Depending on the type, PS can be categorized as a “thermoplastic” or a “thermoset” material. The term refers to how the plastic reacts to heat. Thermoplastic materials are fully liquid […]

HDPE Injection Molding vs. LDPE Injection Molding

Polyethylene (PE) is a versatile thermoplastic that can be made into various forms based on its chemistry. The most common types are high-density polyethylene (HDPE) and low-density polyethylene (LDPE), but there are also many other types. Despite sharing some commonalities, HDPE injection molding vs. LDPE injection molding exhibit distinct chemical structures. These differences give rise to various physical characteristics that in turn define their applications and processing methods. To help you explore all the different variations of polyethylene injection molding, we recommend this article focus on high-density polyethylene, also known as HDPE, and low-density polyethylene, also known as LDPE. Also Read: How to Choose the Best CNC Machining Company for […]

HDPE Injection Molding | Plastic Injection Molding Service

HDPE injection molding has become a game-changing technology in modern manufacturing, changing how many goods are made. This article gives a brief overview of HDPE molding. It talks about how precise, efficient, and essential it is to many different businesses. What is HDPE? High-density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin with a milky white appearance and some clarity in thin sections. It’s natural-colored columnar or oblate pellets with outstanding hardness, tensile strength, creep/wear resistance, and chemical stability. Use-Case of HDPE Molding: Injection molding using HDPE can make parts of various configurations and dimensions. First, the HDPE plastic is melted into a form that can be molded. After […]

CNC加工部品に最適な金属材料

どのような製造プロセスにおいても材料の選択は不可欠だが、エンジニアやCNC機械加工サービスプロバイダーは、CNC機械加工部品に関して細心の注意を払わなければならない。この手順は、金属からグラスファイバー、木材まで、幅広い材料に適しているため、適切な材料を選択することは簡単ですが、作業に最適な材料を選択することはできません。しかし、CNC機械加工プロジェクトに最適な金属材料を選択したい場合もあるでしょう。このブログでは、CNC機械加工部品に最適な金属材料を選択するのに役立つ、いくつかの重要な考慮事項について説明します。CNC機械加工部品用の5つの一般的な金属 金属であれ、どのような材料であれ、製品チームはCNC製造に多くの選択肢を持っています。

射出成形プラスチックの収縮の重要性

射出成形で作られたプラスチックは、射出後に冷却されると収縮する。収縮の大部分は金型内で冷却中に起こりますが、射出された後も冷却が続くため、若干の収縮が生じます。金型から取り出して冷却した後、プラスチック部品の大きさがどの程度小さくなるかを示す。プラスチックの収縮率には、プラスチックの種類、成形条件、金型の構造などが大きく影響します。様々なポリマー材料間で収縮率には大きな幅がある。第二に、[...]...

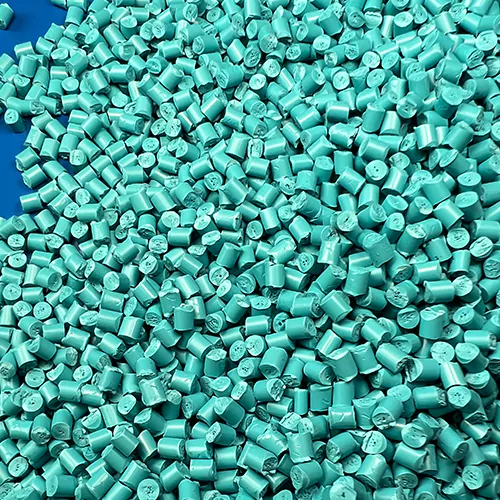

How to Manage the Color Difference Of Injection Molded Parts

In general, chromatic aberration is a prevalent fault in plastic injection molding. And it is found in the injection molding process. But that’s not all the defects that may occur in such parts related to their color differences. As we all know, several factors influence the color difference of finished injection molded parts. It’s no surprise that it’s one of injection molding’s most difficult-to-control technologies. Professional service providers, such as Prototool, understand the types of errors and how to avoid them to supply customers with high-quality injection molded parts. Please continue reading to learn how such businesses do it. How Are Colors Mixed in Injection Molded Parts? · Compounding In this […]

プラスチック製品の肉厚:最も推奨されるリファレンス

射出成形プラスチック製品の肉厚は、その品質に大きく影響します。肉厚が薄すぎると、強度と剛性の要求を満たし、大型で複雑な製品のキャビティに充填することが難しくなります。肉厚が厚すぎると、原材料を無駄にするだけでなく、プラスチック製品の内部にすぐに気泡が発生し、製品の外観に凹みなどの欠陥が生じます。同時に冷却時間も長くなる。その結果、経済的な観点から、プラスチック製品を薄くすることは非常に重要です。プラスチック射出成形用金型を製作する際には、プラスチック製品の厚みが成形工程の要求に合っているかどうかを検討する。もし