In automotive engineering, Interior LED Lamps play a crucial role in providing illumination within car compartments. (Check high-quality car parts manufacturing.) These vital components are a remarkable blend of plastic and aluminum materials, skillfully processed through injection molding and mold-making techniques. The design and manufacture of the components play a pivotal role in the production of Interior LED Lamps parts manufacturing. Specifically, the reflector and lens are critical factors that require careful attention.

The reflector is important in the Interior LED Lamp by directing the emitted light from the LED bulb toward the lens. This ensures optimal illumination of the car compartment. Typically crafted from top-quality plastic material, the reflector is meticulously shaped into a parabolic or elliptical form, meticulously designed to maximize light reflection. The precision involved in the reflector’s design and production stages guarantees the final product’s exceptional quality and efficiency.

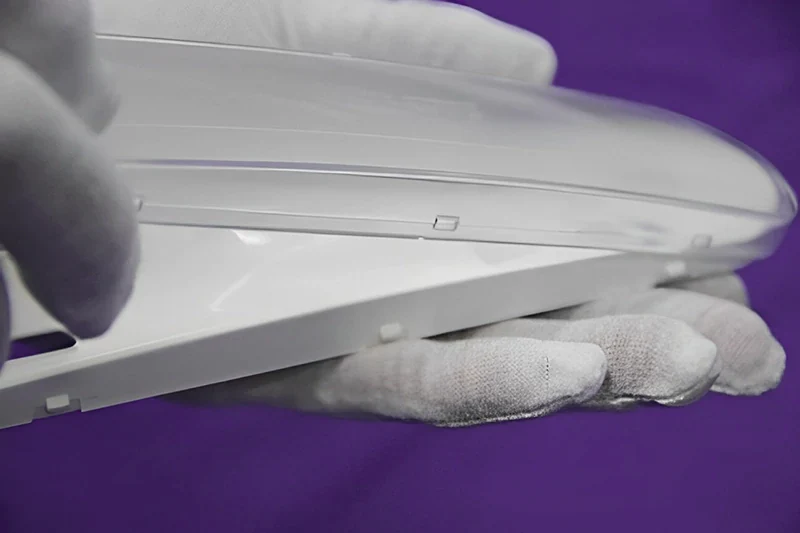

On the other hand, the lens assumes the critical task of uniformly dispersing the light throughout the car compartment. Composed of high-grade acrylic material, the lens undergoes an intricate process of shaping and polishing to achieve the desired light transmission and diffusion level. The utmost precision in the design and manufacturing of the lens is imperative to uphold the highest standards of quality and functionality.

The Interior LED Lamp

– Automotive Industry

The interior LED lamp parts manufacturing process requires meticulous attention to detail, from selecting materials to precisely shaping and assembling the components. By carefully integrating plastic and aluminum through advanced injection molding techniques, coupled with the artful craftsmanship involved in creating the reflector and lens, manufacturers can successfully produce Interior LED Lamp components that shine bright, enhancing the overall driving experience for automotive enthusiasts.

Efficient Tooling Production for Interior LED Lamp Parts Manufacturing: A Case Study

When our client approached us, seeking tooling products for Interior LED Lamps, we swiftly responded within 12 hours—a standard timeframe for production tooling quotes. However, due to the simplicity of the structure and our commitment to efficiency, we managed to slash the response time to 6 hours or even less. This expedited service reduced waiting times for our customers and gave them more valuable assessment time.

Through effective communication, we agreed on utilizing LG CHEM LUPOY RF3208 solid white and Bayer Makrolon PC2647 transparent materials for the project. The RF3208 material was selected for its impressive attributes: exceptional transparency, high-temperature resistance, and remarkable wear resistance, making it an ideal choice for the LED lamp parts. These material selections were made based on the client’s design requirements and valuable input from our CAD engineers.

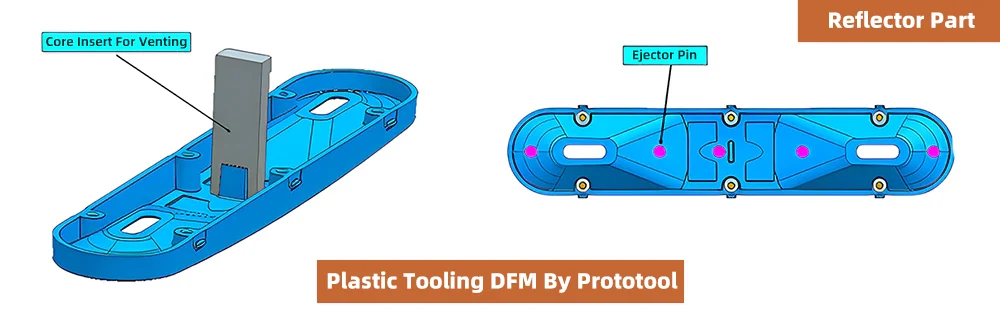

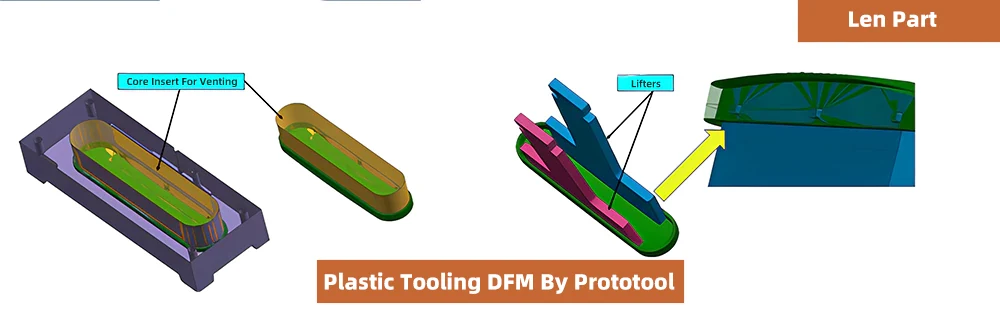

Progressing further, we embarked on the crucial Design for Manufacturing (DFM) communication stage. Here, we meticulously optimized the tooling product design, ensuring seamless integration into the injection molding and mold-making process. Our team of engineers collaborated closely with the client, guaranteeing that the design was compatible with the manufacturing process and enhancing the product’s quality, performance, and overall efficiency. Valuable suggestions were made, fine-tuning the design to achieve the highest standards in all aspects.

By streamlining our processes, engaging in effective communication, and leveraging our expertise, we successfully delivered efficient tooling products for Interior LED Lamps. This case study highlights our commitment to customer satisfaction and our dedication to providing exceptional services in the field of tooling production.

Optimizing Design for Manufacturing (DFM) Process: Illuminating the Interior LED Lamp

DFM stands as a pivotal phase in the manufacturing journey, harmonizing design excellence with efficient and cost-effective production. For our Interior LED Lamp parts manufacturing project, DFM sprang to life within a mere 1 to 2 days upon reviewing the 3D model. This crucial step enabled our adept team to unearth potential manufacturing hurdles and propose design modifications to our esteemed client, paving the way for seamless tooling progression.

Following the initial review, our skilled team diligently crafted the comprehensive DFM report, proudly showcasing the intricacies of the design scheme to the client. The report entailed meticulous details, spanning from the parting line and gating to ejection mechanisms and wall thickness. With the DFM report in hand, collaborative discussions fostered a nurturing environment to resolve design intricacies and ensure optimal manufacturability.

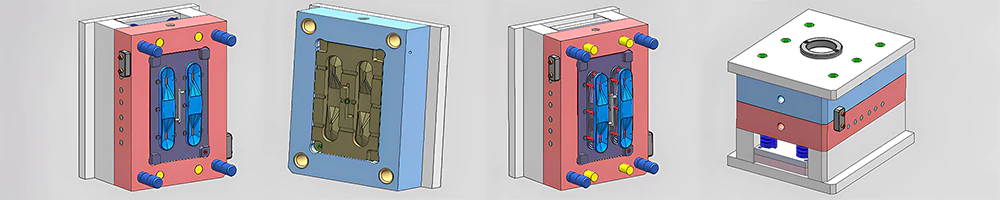

Buoyed by the finalized DFM report, we embarked upon the tooling design process, spearheaded by our seasoned mold designers equipped with cutting-edge software. Their expertise weaved magic, fashioning an impeccable mold design encapsulating every facet with utmost care and consideration. The tooling design synergistically embraced the chosen materials, LG CHEM LUPOY RF3208 solid white and Bayer Makrolon PC2647 clear, ensuring these exceptional resources’ efficient and effective utilization.

By placing unwavering focus on optimizing the Design for Manufacturing (DFM) process, we illuminate the path to unparalleled excellence in Interior LED Lamp production. This vivid account underscores our commitment to seamlessly integrating design and manufacturing, elevating the art of tooling to new heights.

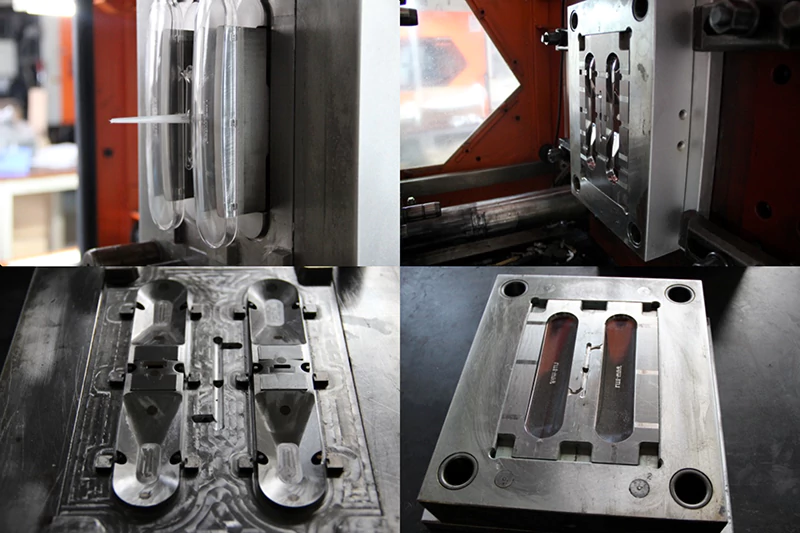

Parts Injection, Testing, and Mold Modification: Pursuit of Excellence

With an unwavering dedication to excellence, we implemented a robust testing protocol to ensure the unparalleled quality of the parts. Every aspect was scrutinized, leaving no room for flaws or defects. Our team promptly addressed detected issues, leaving no stone unturned to deliver the highest quality product.

Assembling Brilliance Step-by-Step

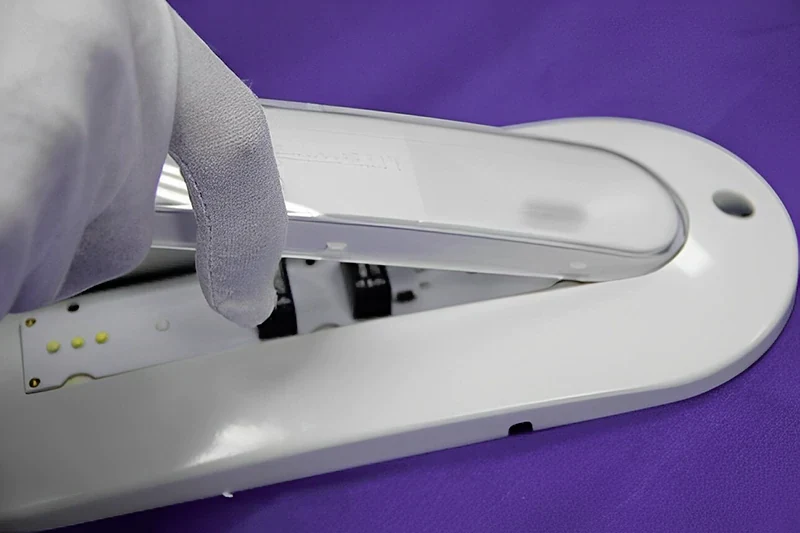

- Accessory parts are seamlessly integrated.

- O-ring expertly installed.

- PCB flawlessly positioned.

- Meticulous assembly of the light-cup.

- Precise installation of the light-cup.

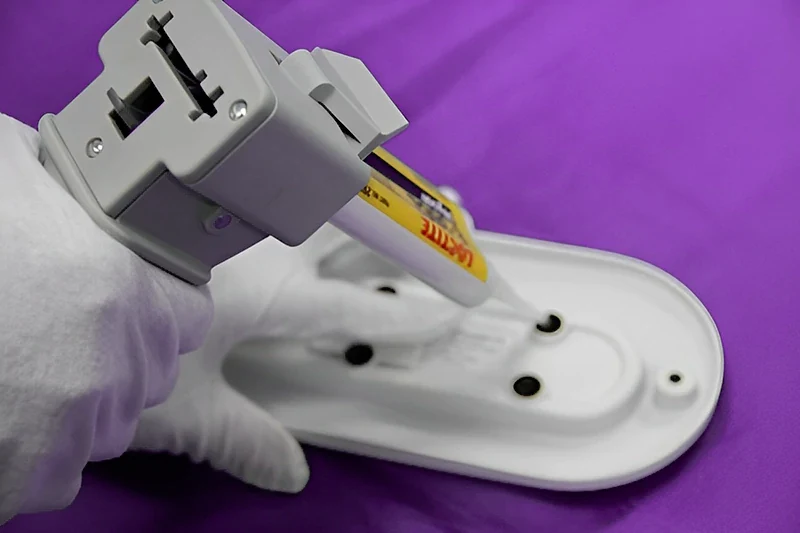

- Flawless gluing techniques employed.

- The finishing touch, a testament to perfection.

Uncompromising Quality Control

Our esteemed QC department holds the illustrious title of the golden supplier, with a meticulous inspection process that leaves no room for error. Every part undergoes rigorous scrutiny, with each detail meticulously compared against the 3D model to ensure precise dimensions within tolerance. Our comprehensive checks encompass running dimensions, lighting assessments, sealing tests, and more.

A Triumph of Excellence

In conclusion, the Interior LED Lamp parts manufacturing case study shines a light on the transformative power of injection molding and mold-making processes in crafting superior LED lamp components. Our team achieved swift turnaround times through a customer-centric approach and the utilization of cutting-edge technologies while steadfastly maintaining an unwavering focus on quality control and design for manufacturing. The success of this project serves as a resounding testament to the pivotal role played by effective communication, collaboration, and a steadfast commitment to meeting customer needs in creating exceptional products.